Ammonia-Powered Engines for Cleaner Transportation

By optimizing air–fuel mixing conditions for efficient ammonia combustion, the study brings us closer to viable ammonia-fuelled vehicles

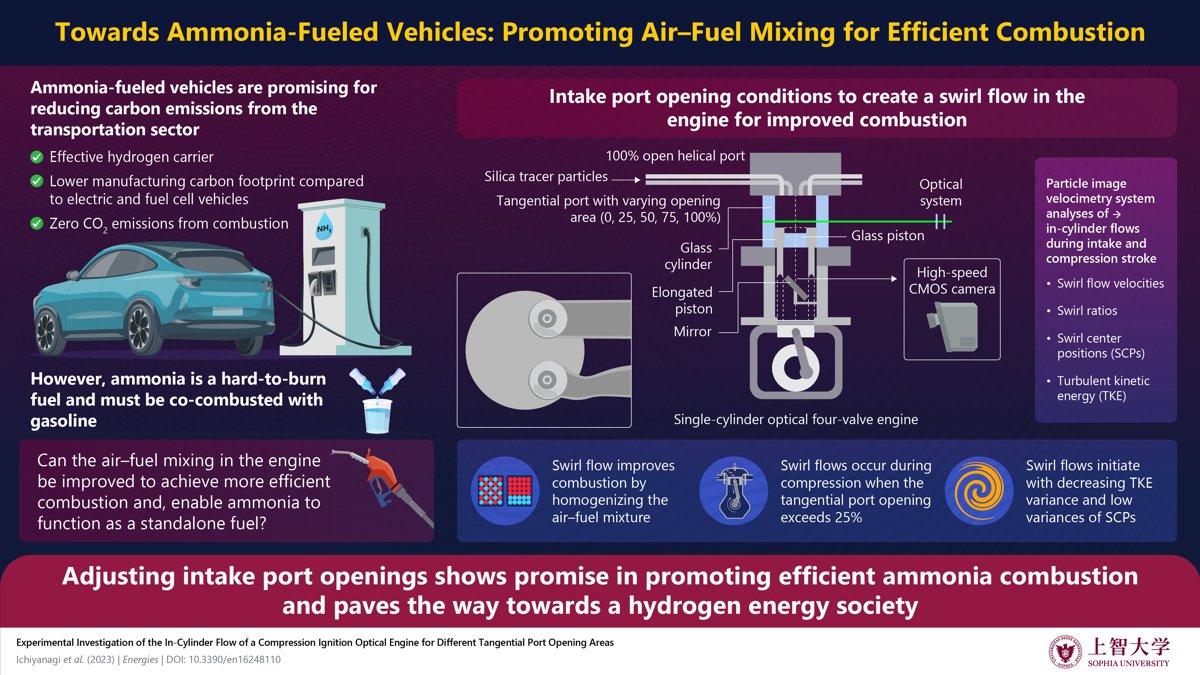

The use of ammonia as a fuel addresses challenges related to hydrogen storage and transport. However, ammonia is a challenging fuel to burn efficiently. Now, researchers at Sophia University have explored intake port opening conditions that lead to swirling flow in engines. They improve the mixing of air and fuel for more efficient combustion. The findings could pave the way for ammonia-fuelled vehicles, supporting the UN’s Sustainable Development Goal for clean and sustainable energy.

While the transportation sector has witnessed a dramatic shift toward electric vehicles (EVs), the idea of using hydrogen as a clean and efficient fuel for transportation has been explored for many decades. These vehicles emit water on combustion, and since they are based on the production of existing engine vehicles, they are expected to have a lower manufacturing carbon footprint than EVs. However, storing and transporting hydrogen requires high pressures and low temperatures, which are energy-intensive processes. To address this, ammonia has been considered as a potential carrier of hydrogen for fuel cells or combustion engines. But ammonia is a hard-to-burn fuel and requires mixing with gasoline for efficient combustion.

Since 2019, Professor Mitsuhisa Ichiyanagi from the Department of Engineering and Applied Sciences at the Faculty of Science and Technology at Sophia University, along with Emir Yilmaz and Takashi Suzuki, also from Sophia University, has been working to design engines where ammonia can be used as a standalone fuel. Their work focuses on intake port opening conditions that enhance the mixing of air with fuel inside the engine cylinder for a more efficient combustion. In a study published in the journal Energies on 17 December 2023, the researchers determine intake port opening conditions that would lead to swirling flow conditions within the cylinder of an engine.

“Airflow within cylinders profoundly affects combustion and emissions by influencing the air–fuel mixing phenomenon,” says Prof. Ichiyanagi. “With the aim of burning only ammonia, we have basically investigated the relationship between the engine’s intake system and the flow inside cylinders.”

Swirling flow refers to a vortex-like pattern of air–fuel mixture entering the engine’s cylinder. This is advantageous as it promotes better mixing of air and fuel, creating a more homogenous mixture, leading to improved combustion and reduced emissions. The researchers conducted their investigation in an optical single-cylinder diesel engine with a glass cylinder and piston. For air intake, the engine used conventional tangential and helical intake ports.

To visualize the air flows in the engine, the researchers introduced silica particles with diameters of 4.65 µm as tracers during the intake stroke and monitored their movement in the engine with a high-speed CMOS camera. Air entering through the helical port develops into swirling patterns, while air from the tangential port initially produces no vortical structure. However, when redirected by the cylinder walls, it eventually generates swirling structures.

In their earlier experiments, the researchers observed that airflow velocity remained relatively constant across various helical port openings. So, leaving the helical port completely open, they varied the opening of the tangential port to 0 %, 25%, 50%, 75%, and 100% to determine its effect on intake and in-cylinder flows during the intake and compression strokes.

The researchers noted the successful generation of swirl flows in the early stage of the compression stroke when the opening of the tangential port was more than 25%. The formation of swirl flows was observed to correlate with low variances of turbulent kinetic energy during the intake stroke and low variances of the swirl centre position during the compression stroke. The observation of swirl flows in the cylinder opens the door to efficient ammonia combustion in the engine. The researchers intend to apply the findings from this study to investigate the combustion characteristics of an ammonia–gasoline mixture or only ammonia in the engine.

Driven mostly by EVs, the demand for lithium is expected to exceed 2.4 million metric tons by the 2030s, a significant increase from the 130,000 metric tons produced in 2022. According to the International Energy Agency, this could lead to potential lithium shortages as early as 2025. In such a situation, ammonia emerges as a promising alternative clean fuel.

Although there are challenges to overcome before ammonia-fuelled vehicles become a reality, this research holds promise for achieving current and future decarbonization goals. “The development of ammonia-fuelled engine vehicles is expected to not only reduce carbon dioxide emissions from engines but also contribute to realizing a hydrogen energy society,” says Prof. Ichiyanagi.