Damage Prevention and Early Detection for Buried Pipelines

The Korea Research Institute of Standards and Science has developed a damage prevention and early detection system for buried pipelines, preventing pipeline failures caused by third-party interference (TPI) and other threats.

TPI is one of the main causes of damage to buried pipelines used for transporting water, petroleum, gas, and other substances. Leaks in damaged pipelines not only lead to environmental contamination but also present risks such as explosions, fires, and sinkholes. However, the prevention still has been challenging for pipeline management entities to detect TPI in advance.

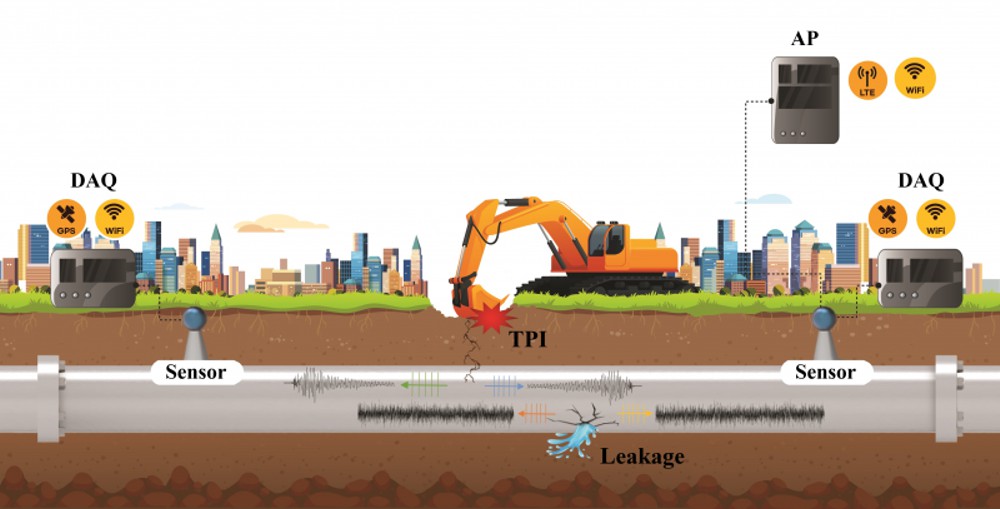

The Non-Destructive Metrology Group at KRISS has developed a real-time monitoring system that identifies actual damage activities before buried pipelines are damaged. When TPI or other threats make a critical impact just around pipelines, the system recognizes it as a risk and gives early warnings to prevent incidents.

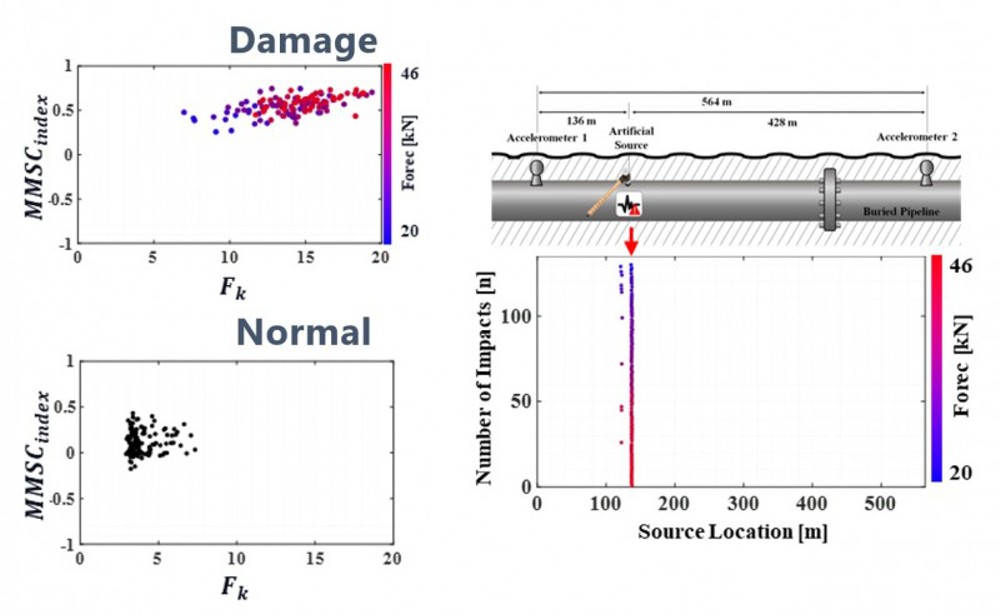

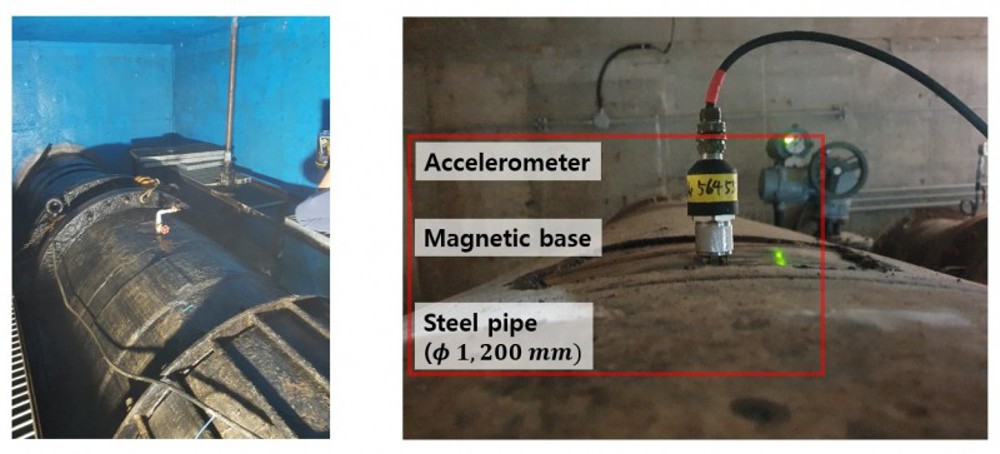

The core technology is based on precise measurement and analytical models of the elastic wave propagated upon impact to the pipelines. With a pair of sensors several hundred meters apart along the pipeline, the system enables the real-time monitoring of impact signals between the sensors. This provides immediate calculation of the time and location of the impact, similar to seismological centres that detect vibrations and localize source position of an earthquake using arrival time of seismic waves.

The sensors can be easily attached to accessible parts exposed from buried pipelines, such as valve chambers or manholes. Moreover, the system incorporates precise analytical algorithms that effectively reduce and filter out unnecessary signals like noise from surroundings: traffic, daily life noise, and so on.

The research team conducted tremendous field experiments to validate the system’s practical applicability to real buried pipelines in operation spanning several kilometres in South Korea. The results demonstrated that the system successfully detected impacts over about 20 kN with an accuracy of over 95 %. Given that typical force causing pipeline damage often in the range of several hundreds kN or more, the system was found to be suitable for the prevention and early warning of pipeline damage incidents.

Conventional monitoring technologies for buried pipelines usually have only focused on detecting leaks after damages occur. This accomplishment by KRISS, therefore, represents the world’s first early detection system for long-distance pipeline damage. The research team completed technology transfers to companies in South Korea and filed patent applications in both the United States and Europe.

The novel system can be applied not only to water pipelines but also to various types of pipelines, including those for oil and gas transportation as well as heat supply. It can be utilized in smart monitoring systems for the online detection and management of abnormal conditions in buried pipelines.

Dr. Dong-Jin Yoon, a principal researcher from the Non-Destructive Metrology Group, said: “Despite the serious risk of major accidents and loss of life due to pipeline breaks, we have had to rely on leakage reports from informants. This technology will contribute to public safety and social cost savings.”