Autocraft to accelerate international EV growth strategy with £24m in finance

Autocraft Solutions Group, a specialist in cutting-edge automotive remanufacturing technologies, has agreed a major financing package with HSBC UK amid plans to rapidly upscale its international EV battery repair footprint.

Worth £24m, the financial package will support the growth of Autocraft’s EV Solutions business as it looks to establish itself in strategic global locations where there is growing demand for its REVIVE® range of EV battery testing, repair and remanufacturing solutions. As the automotive industry strives to become more circular, Autocraft is on track to continue its impressive growth this year by working more closely with its global customer base of OEMs.

With the automotive industry facing higher-than-expected rates of EV battery failure, such packs are being prematurely recycled, despite the vast majority of the battery pack being suitable for remanufacture back into electric vehicles. This carries a heavy environmental and financial cost for the automotive industry as EV ownership rates continue to rise.

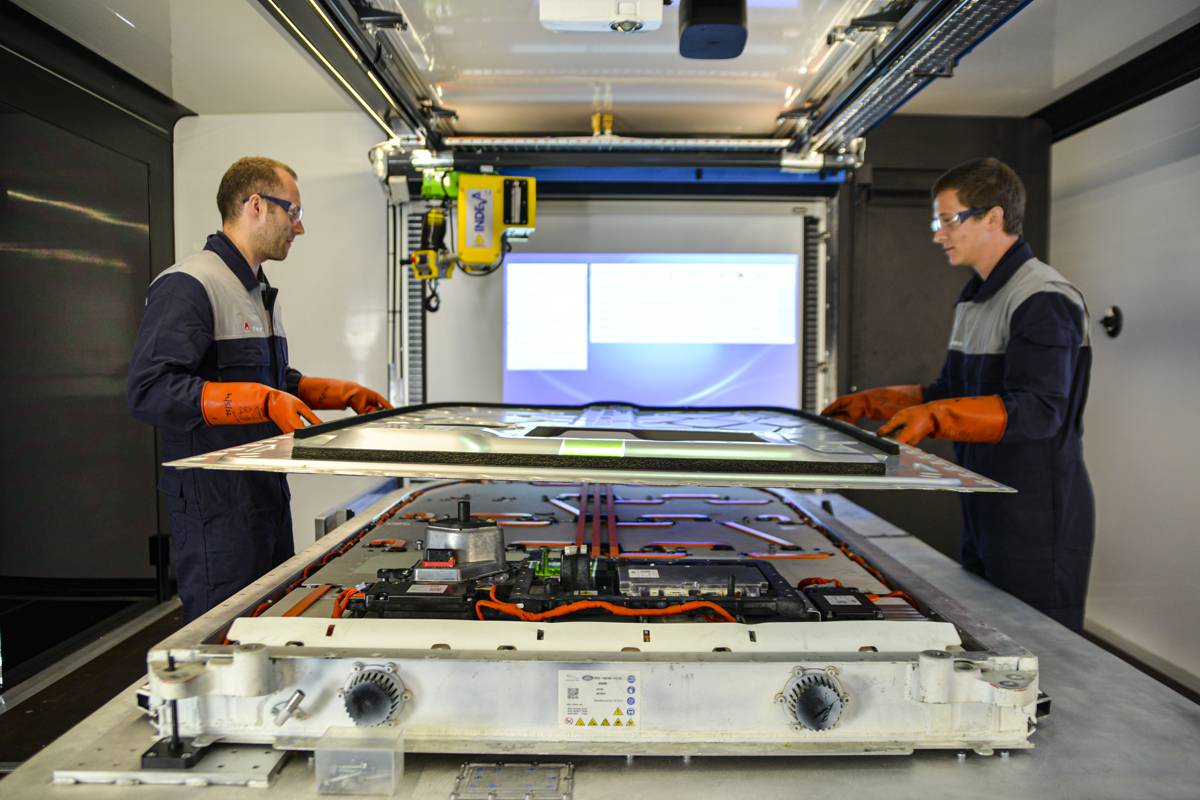

Recognising the environmental imperative to maximise the longevity of each module, Autocraft developed the first industrialised process for EV battery remanufacturing. By identifying and replacing underperforming cells with healthy ones recovered from other packs, it has a proven methodology for restoring and maintaining optimal EV battery performance. Its unrivalled capability in battery state-of-health testing means it can diagnose the root cause of faults on a cellular level, even before they have occurred, so that predictive maintenance can be undertaken.

Following the successful launch of its first European EV battery repair facility in Arnhem, Netherlands, in 2023, Autocraft is keen to maintain momentum and is actively pursuing plans to open new facilities across Scandinavia, Southern Europe, and North America. Each REVIVE® facility will triage, repair and remanufacture EV battery packs, processing 1,400 EV batteries each year. By keeping existing batteries operational, each facility will save around 1,500 tonnes of CO2, six megawatt-hours of electricity, and two million litres of water per year by eliminating the need for OEMs to produce replacement battery packs.

As the EV parc rapidly increases, so too does the number of EV battery pack failures, whilst increasingly sophisticated battery technology adds significant complexity to the repair process. Since few dealerships are equipped to carry out battery repairs with the required level of precision and speed, this culminates in high rates of repeat failure and excessive timescales for repair, with both undermining confidence in EV.

By industrialising the remanufacturing process, Autocraft has ensured that the optimal conditions for a safe, reliable, and speedy repair process are met, thereby shielding OEMs from the risk of repeat failures. Moreover, this capability can play a key role in eliminating uncertainty around long-term EV battery health, a major obstacle to widespread adoption.

Mike Hague-Morgan, Executive Director at Autocraft Solutions Group, said: “The number of EVs continues to rise, bringing with it increased demand for our world-class remanufacturing capabilities. We are on a mission to unlock the full environmental and performance potential of EVs and, with the financial backing of HSBC, we are now one step closer to making this a reality. Importantly, the bank also shares our passion for green tech, making it the ideal partner to support our next phase of growth.

“To reach net-zero, we simply cannot allow for battery packs to be prematurely recycled. Our remanufacturing capability ensures we can maximise battery life by restoring optimal health, with all the environmental benefits this brings. Expanding our global footprint will allow us to work more closely with the worldwide automotive industry, helping it to significantly reduce its environmental impact, while instilling confidence in EV.”

Despite its growing focus on the eMobility market, Autocraft remains committed to ICE remanufacturing, highlighting a strong environmental case for its services. Not only is it more sustainable to prolong the life of automotive components, its expertise in ICE manufacturing frees up valuable resources for automakers to invest in transitioning to cleaner forms of propulsion.