NanoBioLubricants to make Industrial Grinding practices Eco-Friendly

Traditional grinding processes heavily depend on metalworking fluids that contain harmful chemicals, posing significant environmental and health risks.

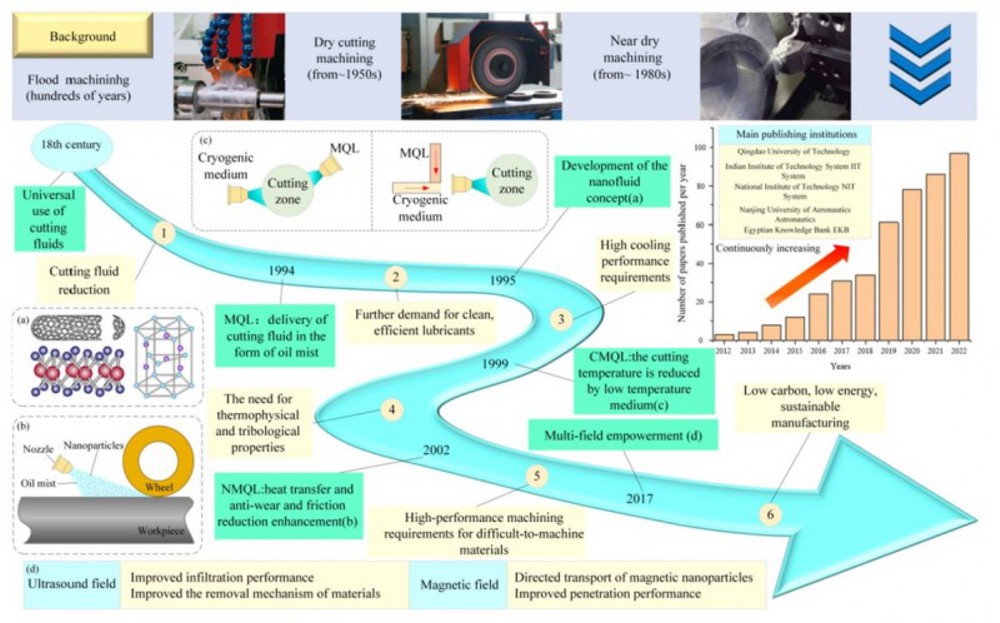

As the industry shifts toward sustainability, there is an increasing demand for efficient alternatives that mitigate these concerns. NanoBioLubricants, which enhance biodegradable oils with nanoparticles, provide a viable solution. They aim to enhance grinding performance while substantially reducing ecological footprints.

A recent review published in Advances in Manufacturing on March 9, 2024, highlights significant advancements in the use of NanoBioLubricants for grinding operations, showcasing a sustainable and efficient approach that seamlessly integrates environmental consciousness with industrial performance.

These innovative lubricants utilize nanoparticles to enhance the properties of vegetable oil-based fluids, offering a dual benefit of superior lubrication and environmental safety. The research details how nanoparticles such as silicon oxide and molybdenum disulphide, known for their high thermal conductivity and robust film-forming abilities, are integrated into biolubricants to significantly improve heat transfer rates and reduce friction at the grinding interface.

This synthesis of nanoparticles with biolubricants not only preserves the physical integrity of grinding wheels but also prevents thermal degradation of the workpiece, thus ensuring smoother operations and extending the lifespan of manufacturing tools. Additionally, the study highlights the role of these nanoparticles in forming a chemically and physically stable lubrication layer that withstands the extreme conditions of industrial grinding.

Dr. Chang-He Li, a senior researcher involved in the study, emphasizes: “Our research demonstrates that NanoBioLubricants can drastically improve the thermal and friction dynamics at the grinding wheel-workpiece interface. This not only enhances the grinding performance but also significantly cuts down on energy consumption and environmental impact.”

This technology not only aligns with global environmental goals but also offers substantial cost savings in operations, setting a new standard for eco-friendly industrial practices. As industries worldwide strive for greener solutions, the adoption of NanoBioLubricants could mark a crucial step in fostering a more sustainable and responsible manufacturing landscape.