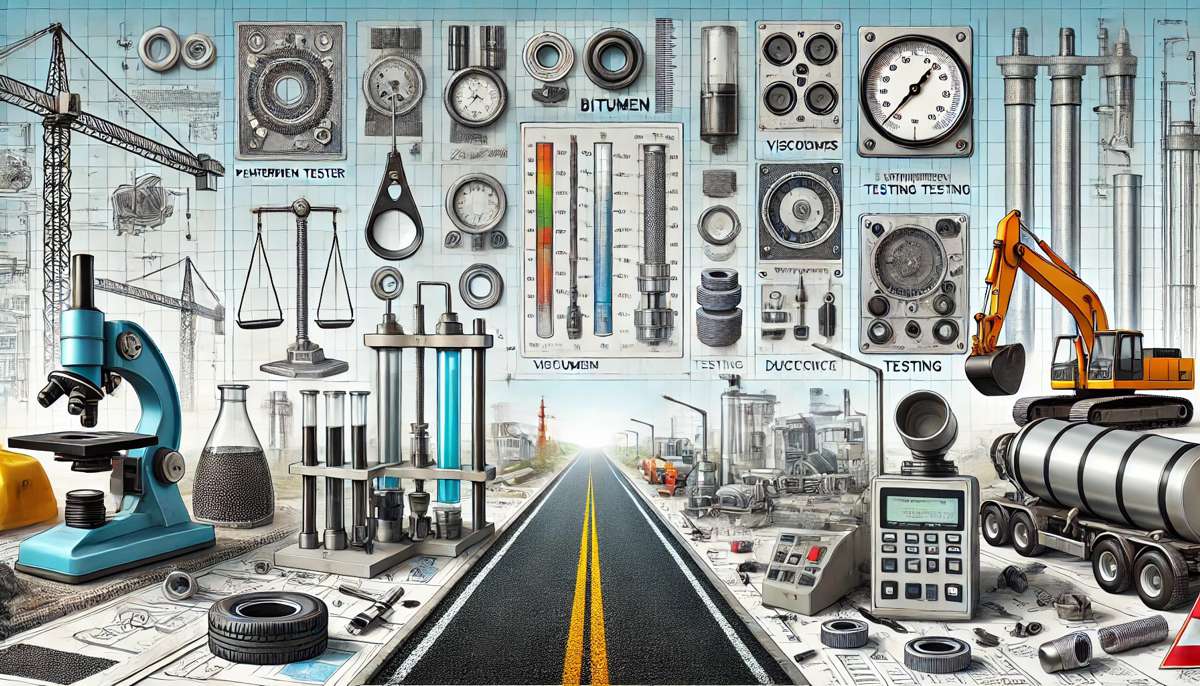

Understanding Bitumen Specifications, Tests and Properties

Bitumen, a cornerstone in road construction and roofing, is a complex material with unique responses to stress. Its viscoelastic nature means it can behave as both a solid and a liquid, depending on the conditions.

This dual behaviour is influenced by temperature and the duration of applied force, making the understanding of bitumen properties essential for construction professionals.

Bitumen Behaviour and Characteristics

Bitumen’s reaction to stress varies:

- Low temperatures and short loading times: Acts like an elastic solid.

- High temperatures and long loading times: Behaves like a viscous liquid.

- Normal conditions: Exhibits both viscous and elastic properties.

Given this complexity, bitumen’s performance is heavily dependent on temperature and loading time, necessitating various tests to characterize its properties.

Key US Bitumen Tests

Several tests are employed to evaluate bitumen properties, each designed to measure specific attributes critical to its performance in construction.

- Penetration Test (ASTM D5): The penetration test is a fundamental measure of bitumen’s hardness or softness. In this test, a standard needle, under a weight of 100 grams, is allowed to penetrate the bitumen sample for five seconds at a controlled temperature of 25°C. The depth of penetration, measured in tenths of a millimetre, indicates the bitumen’s consistency. This test is crucial because it helps determine the suitability of bitumen for different climatic conditions; lower penetration values are preferred in hotter climates to avoid excessive softening.

- Ductility Test (ASTM D113): Ductility is a measure of bitumen’s ability to deform under stress. In this test, a standard sample of bitumen is elongated in a controlled environment until it breaks. The distance it stretches before breaking, measured in centimetres, indicates its ductility. This property is particularly important for ensuring that the bitumen can withstand the deformations that occur in pavements without cracking, ensuring longevity and durability of road surfaces.

- Softening Point Test (ASTM D36): The softening point test determines the temperature at which bitumen reaches a particular degree of softness. Using the Ring and Ball apparatus, a bitumen sample is heated at a controlled rate, and the temperature at which the sample softens sufficiently to allow a steel ball to pass through is recorded. This test is crucial for determining the bitumen’s performance in high-temperature environments, indicating its resistance to softening under summer heat.

- Specific Gravity Test (ASTM D70): The specific gravity test measures the density of bitumen compared to water. This is important because the density affects how bitumen is applied and mixed with aggregates in paving. By determining the specific gravity, engineers can calculate the volume of bitumen required, ensuring accurate mix designs and effective material usage. This test typically involves a pycnometer or a cube specimen of the bitumen.

- Viscosity Test (ASTM D2171): Viscosity denotes the flow characteristics of bitumen at a given temperature. This test uses a capillary viscometer to measure the time it takes for a specified volume of bitumen to flow through a capillary tube under controlled conditions. Viscosity is a critical parameter as it affects the ease of mixing and compaction of bituminous mixes. The results help in ensuring that the bitumen will form a uniform film over aggregates, providing necessary binding and durability to the pavement.

- Flash and Fire Point Test (ASTM D92): Safety in handling bitumen is paramount, and the flash and fire point test determines the temperatures at which bitumen vapours ignite. The flash point is the lowest temperature at which vapours briefly catch fire, while the fire point is the temperature at which the bitumen ignites and continues to burn. These tests ensure safe heating practices by defining temperature limits to prevent hazardous situations during bitumen processing and application.

- Float Test (ASTM D139): The float test is used to measure the consistency of bitumen when other tests, like penetration or viscosity, are not applicable. The test involves timing how long it takes for water to pass through a bitumen sample in a specified apparatus. This test provides a float value in seconds, indicating the bitumen’s consistency, which helps in determining its applicability for various paving conditions and ensuring proper performance in service.

- Water Content Test (ASTM D95): Minimising water content in bitumen is essential to prevent foaming during heating, which can affect the material’s application and performance. The water content test involves mixing a bitumen sample with a petroleum distillate, heating it, and measuring the condensed water. Ensuring water content does not exceed 0.2% by weight helps in maintaining the quality and effectiveness of the bitumen.

- Loss on Heating Test (ASTM D6): The loss on heating test evaluates the bitumen’s volatility loss when exposed to high temperatures. A sample is heated at 163°C for five hours, and the weight loss is measured. This test is crucial for determining the bitumen’s stability and suitability for hot climates, ensuring that it does not lose too much mass and thus retains its binding properties in pavement applications.

British Standards for Bitumen Testing

In the UK, British Standards (BS) provide specific guidelines and methods for testing bitumen, ensuring consistency and reliability in its use for construction.

- Penetration Test (BS EN 1426): Similar to the ASTM method, this test measures the depth a standard needle penetrates the bitumen under specified conditions. It helps determine the hardness or softness of bitumen, providing essential data for its application in varying climatic conditions.

- Softening Point Test (BS EN 1427): This test determines the softening point of bitumen using the Ring and Ball method, as per British Standards. It identifies the temperature at which bitumen becomes soft enough to allow a steel ball to fall through, which is crucial for understanding its performance in high-temperature environments.

- Fraass Breaking Point (BS EN 12593): The Fraass breaking point test measures the temperature at which bitumen transitions from a flexible to a brittle state. This test involves cooling a thin layer of bitumen on a steel plate and bending it until it cracks. The breaking point indicates the material’s performance at low temperatures, ensuring it remains resilient in cold climates.

- Viscosity Test (BS EN 12595): This test measures the viscosity of bitumen using a rotational viscometer. The method involves heating the bitumen and measuring the resistance to flow under controlled conditions. Viscosity data is critical for ensuring proper mixing, handling, and compaction of bituminous materials in paving applications.

- Elastic Recovery (BS EN 13398): Elastic recovery is a measure of the bitumen’s ability to return to its original shape after deformation, particularly important for polymer-modified bitumens. This test stretches a sample to a specified length and measures the percentage of recovery, providing insight into the material’s elastic properties.

- Dynamic Shear Rheometer (DSR) (BS EN 14770): The Dynamic Shear Rheometer test assesses the viscoelastic properties of bitumen. It measures the complex shear modulus and phase angle under varying temperatures and stress conditions. This test provides a comprehensive understanding of bitumen’s behaviour under realistic service conditions.

- Multiple Stress Creep and Recovery Test (MSCRT) (BS EN 16659): Using the Dynamic Shear Rheometer, the MSCRT evaluates the elastic response and susceptibility to permanent deformation of bitumen. This test involves applying multiple stress cycles and measuring the material’s recovery, which helps in understanding its performance under repeated loading conditions.

- Bending Beam Rheometer (BBR) (BS EN 14771): The Bending Beam Rheometer test assesses bitumen’s stiffness and ability to dissipate stress at low temperatures. By applying a constant load to a sample in a cold environment, this test provides data on the material’s low-temperature performance, ensuring it remains flexible and durable in cold climates.

Ageing Tests

- Short-Term Ageing: RTFOT Method (BS EN 12607-1): The Rolling Thin Film Oven Test simulates the short-term ageing of bitumen during mixing and transportation. By exposing a thin film of bitumen to heat and air, this test predicts the material’s performance and stability through the production process.

- Long-Term Ageing: PAV Method (BS EN 14769): The Pressure Ageing Vessel test simulates the long-term ageing of bitumen, representing years of service life. By subjecting the material to high pressure and temperature, this test helps predict the durability and longevity of bitumen in real-world conditions.

Ensuring Quality and Durability

Bitumen’s unique properties and responses to environmental conditions make it a critical material in construction. Through a series of rigorous tests and adherence to international and British standards, its performance can be accurately characterised and optimised for various applications.

Understanding these tests and specifications is essential to ensure the quality and durability of bituminous materials in their projects.