Nissan Revolutionising Perfection with AI Paint Process

Nissan has always prided itself on delivering vehicles that reflect quality and craftsmanship. But now, thanks to artificial intelligence (AI) and machine learning, Nissan is pushing the envelope even further in ensuring their cars don’t just look good – they’re flawless.

The meticulous art of automotive painting has entered a new era, with Nissan leading the way in using AI to perfect every painted surface of their vehicles. Whether it’s the sleek Electric Blue of the Sentra or the rugged Baja Storm of the Rogue, the finish is now better than ever.

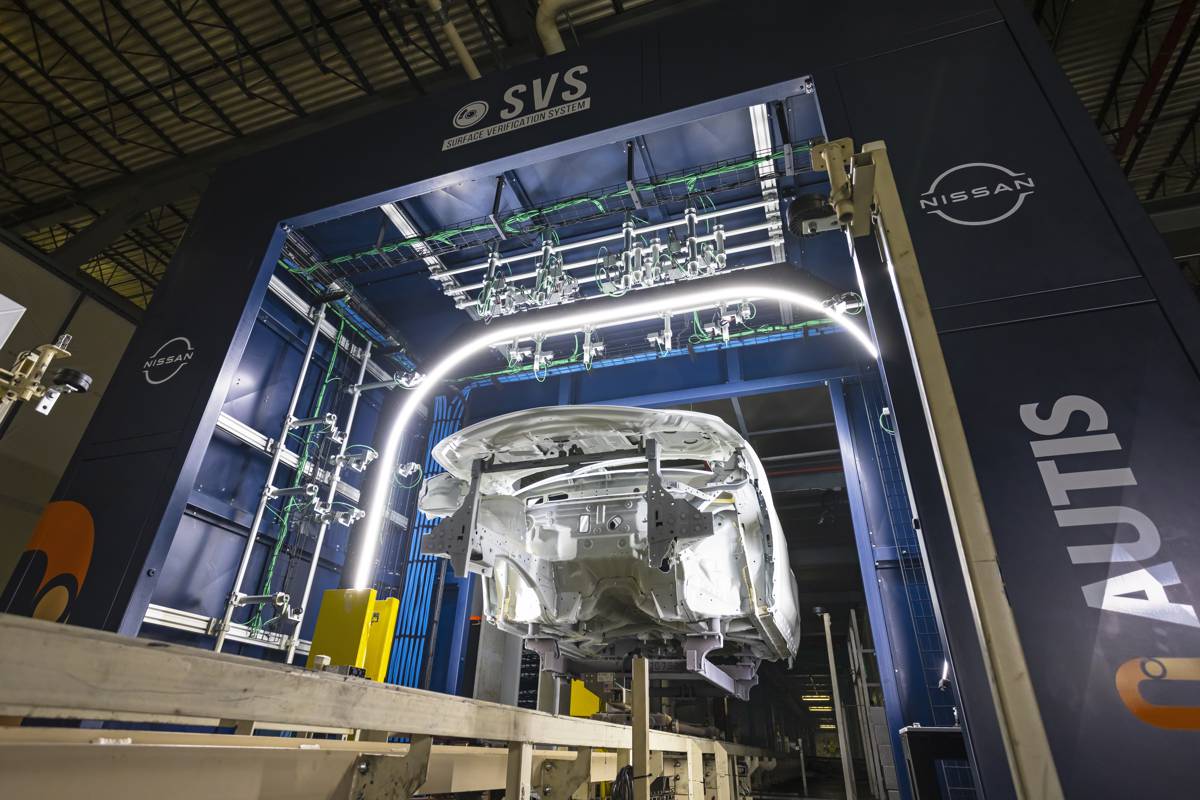

Nissan’s use of AI, particularly through its innovative AUTIS Surface Verification System, is fundamentally changing how the company detects and corrects paint imperfections. In fact, AI is not just improving the quality of the finish; it’s reshaping the entire paint process.

The Role of AI in Nissan’s Paint Process

In an industry where appearances are everything, a flawless paint job is essential. It’s often the first thing customers notice, even if they don’t consciously realise it. That mirror-like shine or the smooth, even coat that highlights the contours of a Nissan vehicle is a subtle indicator of quality. But delivering that perfection involves a complex, multi-step process that’s highly susceptible to errors. Enter AI.

Nissan applies nearly two gallons of paint to each vehicle, with three layers covering the car – primer, base coat, and a clear protective layer. Even in the most controlled environments, imperfections like dirt particles, fibres, or minute craters can mar the surface. But now, Nissan has an ace up its sleeve: the AUTIS Surface Verification System. This advanced technology is driven by AI and machine learning, identifying flaws with a level of precision that surpasses the human eye.

By analysing high-resolution images of each vehicle as soon as it’s painted, AUTIS has helped Nissan increase its defect detection rate by an impressive 7% at its Smyrna, Tennessee plant. It’s a game-changer.

How AUTIS Identifies Imperfections

So, how does AUTIS work its magic? The system uses state-of-the-art cameras to capture an astonishing 15,000 images of each vehicle immediately after it leaves the paint booth. These images are then rapidly processed and analysed, flagging even the tiniest imperfections.

“The human eye can spot 85%-95% of flaws, but AUTIS identifies over 98%,” says Travis Fritsche, a paint process engineer at Nissan. This increased detection rate translates to a higher standard of quality and, ultimately, a more polished product.

When AUTIS detects a potential flaw, it alerts technicians who can immediately view the flagged imperfections on monitors or even wrist-worn devices. This tech-centric process not only reduces eye strain for the team but also increases their efficiency. “Technicians are critical for confirming and categorising defects. AUTIS is a tool to enhance their work, not replace it,” explains Rod Lynch, a new model paint engineer at Nissan.

AI and Machine Learning

One of the key benefits of AUTIS lies in its ability to learn and evolve. This isn’t just any AI system – it’s powered by machine learning, which means it gets smarter with time. The more defects it encounters, the more adept it becomes at recognising and categorising them. From dirt to fibre fragments, the system builds a comprehensive library of potential flaws.

“It’s a self-learning system,” Lynch says. “With feedback from technicians, AUTIS learns to recognise defects like dirt, fibres, and craters. It will continue to refine and build a library of what defects look like.”

This ongoing learning process helps Nissan address recurring issues by grouping defects based on vehicle type and paint colour. This data-driven approach allows the team to spot patterns and fix root causes, resulting in fewer defects over time.

Nissan’s Legacy of Innovation in Paint Inspection

This isn’t Nissan’s first foray into advanced paint technology. In fact, the company has a long history of innovation in this area. Back in 1985, Nissan became the first automaker to use laser-equipped robots for paint inspections, detecting imperfections as small as 0.3 millimetres in just 45 seconds.

Fast forward to today, and AUTIS takes that legacy to the next level. The system can now detect imperfections as tiny as 0.2 millimetres, and it does so in less than half the time it took decades ago. That’s nearly 40 years of technological progress, and the results are undeniable. The AUTIS system has already evaluated over 500,000 vehicles at the Smyrna Vehicle Assembly Plant alone, and it’s also operational at Nissan’s other plants in Canton, Mississippi, and Aguascalientes, Mexico.

These plants produce a range of popular models, including the Altima, LEAF, Rogue, Kicks, Sentra, and Murano, all benefiting from the heightened quality control that AUTIS delivers.

Enhancing Expertise with AI

While AI is transforming Nissan’s paint process, it’s essential to highlight the critical role humans continue to play. AUTIS is a tool – a powerful one – but it’s not meant to replace human workers. Instead, it complements their expertise, enabling them to focus on what they do best: ensuring that Nissan vehicles meet the highest standards.

“Technicians are still the backbone of the process,” says Fritsche. “AUTIS has significantly reduced our investigation time and elevated our quality, but it’s the technicians who confirm and fix the issues.”

This symbiotic relationship between human expertise and AI technology is a hallmark of Nissan’s approach to quality control. The result is a more efficient process that delivers better vehicles to customers.

What’s Next for Nissan’s AI-Powered Paint Process?

As Nissan continues to refine its paint inspection process, the possibilities are vast. With machine learning enabling continuous improvement, AUTIS will only get better at detecting defects and optimising processes. The system is already helping Nissan reduce downtime, increase efficiency, and enhance the quality of its vehicles. And as AI technology advances, so too will the standards of craftsmanship at Nissan.

But it doesn’t stop there. AI’s impact on the automotive industry extends beyond paint. From autonomous driving systems to smart manufacturing, Nissan is at the forefront of integrating AI into every facet of vehicle production.

A New Era of Excellence

By blending cutting-edge AI with human expertise, Nissan is setting new benchmarks for quality in the automotive industry. The use of AUTIS is just one example of how the company is leveraging technology to ensure its vehicles don’t just look perfect but perform perfectly, too.

For Nissan, the future is clear: it’s one where AI and humans work hand in hand to achieve excellence in every aspect of vehicle production.