Cortec Revolutionising Fire Sprinkler Corrosion Protection with Vapor Pipe Shield

In the ever-evolving realm of fire protection, a ground-breaking development is making waves: the Vapor Pipe Shield.

This innovative system, introduced by General Air Products in 2023, is poised to revolutionise corrosion prevention in dry and pre-action fire sprinkler systems. Recent test results underscore its efficacy, suggesting a paradigm shift in how the industry approaches corrosion mitigation.

The Challenge of Corrosion in Dry Fire Sprinkler Systems

Dry pipe fire sprinkler systems are indispensable in environments susceptible to freezing temperatures or in spaces housing sensitive assets—think hospitals, museums, and data centres. These systems remain devoid of water until activation, preventing potential water damage to delicate equipment and artefacts. However, the absence of water doesn’t equate to immunity from corrosion. Over time, internal corrosion can compromise system integrity, leading to costly repairs or, worse, system failures during critical moments.

Traditionally, the industry has leaned on nitrogen generators to combat this issue. By purging oxygen and introducing nitrogen, the aim is to create an environment less conducive to corrosion. This method aligns with the NFPA 13 Standard for the Installation of Sprinkler Systems, allowing contractors to utilise a Hazen-Williams C-Value of 120 for hydraulic calculations. Yet, maintaining the requisite 98% nitrogen purity has proven challenging in practical applications.

A New Era in Corrosion Protection

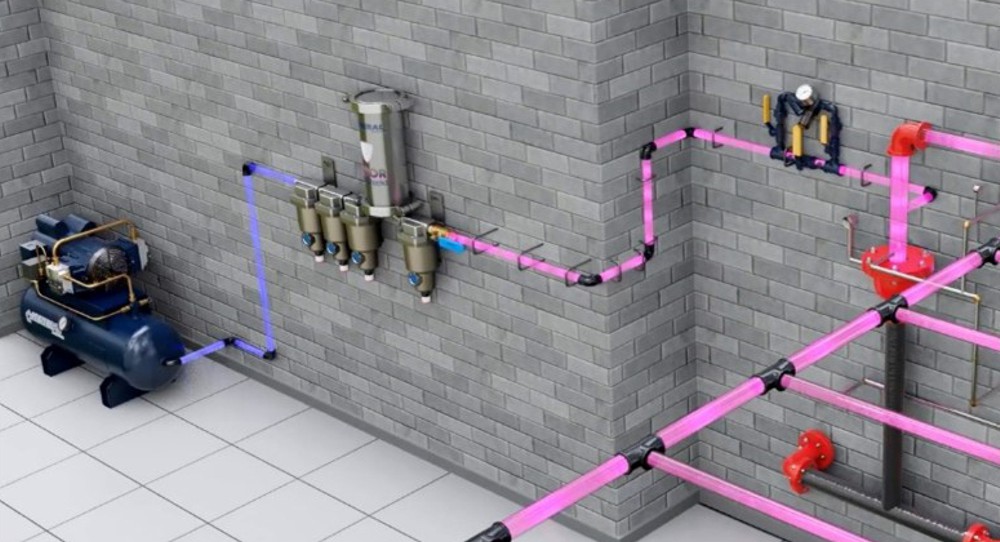

General Air Products, in collaboration with Cortec® Corporation, has unveiled the Vapor Pipe Shield—a patented, UL Listed system designed to simplify and enhance corrosion prevention. Unlike traditional methods, this system employs Vapor phase Corrosion Inhibitors (VpCIs) to form a protective molecular barrier inside the piping network.

Fully mechanical and devoid of electrical dependencies, the Vapor Pipe Shield integrates seamlessly between the air compressor and the dry pipe valve. As air flows through the system, it carries VpCI® molecules into the sprinkler pipes, where they adhere to metal surfaces, creating a one-molecule-thick shield against corrosion.

Compelling Test Results

To evaluate the effectiveness of the Vapor Pipe Shield, General Air Products commissioned Corrosion Testing Laboratories, Inc. for a comprehensive five-year study.

The initial findings, released in December 2024, were striking: VpCI® protection was up to seven times more effective on carbon steel samples partially submerged in water compared to systems utilising 98% nitrogen. This data not only highlights the superiority of VpCI® technology but also prompted the 2025 edition of NFPA 13 to extend the 120 C-Factor allowance to include VpCI® delivery systems like the Vapor Pipe Shield.

This endorsement signifies a significant shift in industry standards, validating the system’s efficacy and encouraging its widespread adoption.

Advantages of VpCI® Technology

The benefits of VpCI® technology extend beyond mere corrosion protection:

- Simplicity and Maintenance: The system is straightforward to install, akin to an air maintenance device, and requires minimal upkeep.

- Energy Independence: Being fully mechanical, it operates without the need for electricity, enhancing reliability.

- Comprehensive Protection: VpCI® molecules safeguard metal surfaces even in the presence of corrosive elements like oxygen, water, or chlorides.

- Thorough Coverage: The protective vapor permeates the entire system, including hard-to-reach areas such as branch lines, ensuring uniform protection.

Industry Adoption and Future Prospects

Since its launch in March 2023, the Vapor Pipe Shield has seen rapid adoption across North America, with over 500 installations to date. Ray Fremont Jr., President of General Air Products, remarked: “That milestone speaks not only to the effectiveness of VpCI® technology but also to its growing recognition as a game-changer for corrosion mitigation in dry and pre-action fire sprinkler systems.”

Looking ahead, the partnership between General Air Products and Cortec® Corporation aims to further refine and expand the application of this technology, ensuring that critical fire protection systems remain reliable and durable.

A Bright Horizon for Fire Protection

The emergence of the Vapor Pipe Shield marks a significant advancement in fire sprinkler system technology. By addressing the persistent challenge of corrosion with innovative solutions, the industry is taking a proactive step towards enhancing safety and reliability.

As this technology continues to gain traction, stakeholders can anticipate a future where fire protection systems are more robust, efficient, and dependable.