HaloDrive Axial Flux Motor Powering the Next Wave of e-Mobility Innovation

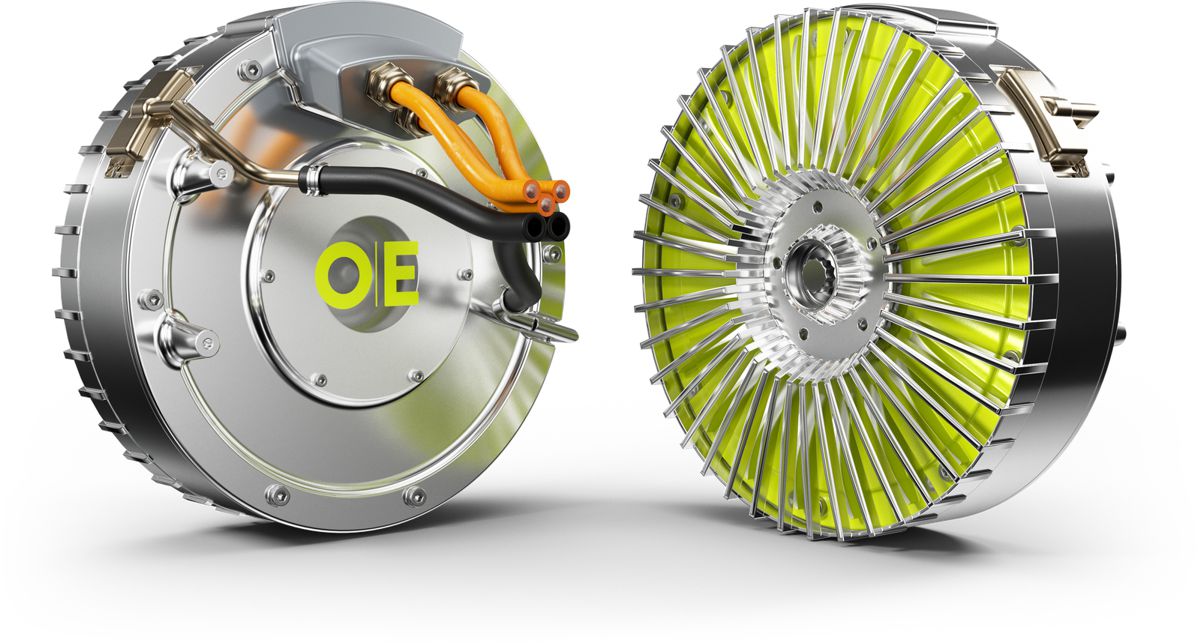

In an era where electrification is no longer optional but essential, Orbis Electric has taken a bold step forward. The California-based company has pulled the wraps off HaloDrive, a revolutionary axial flux motor-generator that’s already turning heads across industries. From its injection-moulded plastic stator to its modular construction and jaw-dropping torque, this motor isn’t just a contender—it’s a game-changer.

HaloDrive isn’t another incremental update. It’s a full-scale reinvention of what an electric motor can do and where it can go. Designed to serve a broad spectrum of applications. including electric vehicles, trucks, marine systems, aerospace platforms, and even stationary industrial power generation. HaloDrive is aiming squarely at the heart of the energy transition.

Outmuscling the V8, Outclassing the Competition

Here’s the headline: HaloDrive matches the torque of a V8 engine, delivering an astonishing 100 Nm/kg torque density. To put that in perspective, that’s significantly higher than what you’d find in conventional radial or axial flux motors. Better still, it does all this while being slimmer, lighter, and more cost-effective.

“With HaloDrive, we offer a high-performance axial flux motor that is not only highly efficient and powerful but also environmentally sustainable,” said Chance Claxton, CEO of Orbis Electric.

This isn’t a pipe dream. Orbis has already piloted HaloDrive with several passenger vehicle OEMs for in-wheel propulsion and with heavy-duty trucking fleets as a diesel replacement generator. In one notable trial, a customer reported a 61% boost in fleet fuel efficiency.

Modularity Makes It Magic

What sets HaloDrive apart isn’t just brute force—it’s brains too. The four-part modular design offers unparalleled flexibility. Whether it’s a P2, P3, P4, or P5 configuration, HaloDrive slips into position without requiring structural modifications. That means faster integration, quicker time-to-market, and less engineering overhead.

And it doesn’t stop at mobility. When deployed as a generator, the HaloDrive system can be installed in under three hours. That’s game-changing for sectors like construction or shipping where downtime comes with a hefty price tag.

Fuel-Free Cooling for the Cold Chain

One of the most promising use cases for HaloDrive lies in commercial transport refrigeration. Known as eTRU (Electric Transport Refrigeration Units), these setups traditionally rely on diesel. But HaloDrive offers a clean break: installed on a truck’s driveshaft or axle, it captures braking energy and converts it into electricity for cooling—completely off-grid.

The benefits here are hard to ignore:

- Up to 100% reduction in diesel refrigeration fuel usage

- 90% reduction in operating costs

- Emissions cut to nearly zero

In an industry under increasing regulatory scrutiny, those numbers spell major savings and compliance wins.

Tackling the Motor Efficiency Crisis Head-On

According to the U.S. Environmental Protection Agency, transportation accounts for 39% of the country’s CO2 emissions. Globally, it’s responsible for about 12%. Yet here’s the kicker: one-third of the world’s electricity is being guzzled by inefficient electric motors.

This is where Orbis Electric sees an opportunity. With HaloDrive operating at up to 97% efficiency, there’s a chance to slash emissions by as much as 1.4 billion metric tonnes of CO2 globally. That’s not a typo. That’s the kind of impact that rewrites the playbook.

“We can achieve exceptional performance while also mitigating risks tied to rare earth materials, ensuring consistent availability and pricing stability,” said Marcus Hays, Founder and CTO of Orbis Electric.

In a market still reeling from supply chain shocks and rare earth dependencies, that promise of price stability and environmental responsibility is a major feather in Orbis’s cap.

Engineering for the Future, Built for Today

From aerospace to agriculture, passenger cars to container ships, the versatility of HaloDrive is its superpower. Its plastic injection-moulded stator cuts weight and cost while enhancing thermal stability. That’s not just smart engineering—it’s market readiness.

Here are a few more key takeaways:

- Torque Matching a V8: Instant torque delivery of 100 Nm/kg

- 35% Lower Drivetrain Costs: Compared to radial flux counterparts

- Plug-and-Play Generator Installation: Under three hours to deploy

- Scalable Configurations: Modular design adapts to different drivetrain architectures

It’s not just about ticking boxes. HaloDrive is designed to serve sectors with serious energy and efficiency demands, and it’s doing so without compromise.

Partnering to Power the Next Revolution

Orbis Electric isn’t going it alone. With HaloDrive now available for commercial rollout, the company is actively looking for Tier 1 production partners, OEMs, and industrial operators eager to transition to cleaner energy platforms.

There’s a growing urgency across sectors to meet sustainability targets, and many companies are finding themselves constrained by legacy systems. HaloDrive offers a way out—a high-performance, future-ready technology that eliminates traditional roadblocks around cost, material dependency, and integration complexity.

Electrifying Possibilities Ahead

From decarbonising road freight to keeping perishable goods cool without diesel, the possibilities with HaloDrive are as expansive as they are practical. And with transport emissions squarely in the crosshairs of climate policy worldwide, solutions like these aren’t just nice-to-have—they’re essential.

By reimagining what an electric motor can do, Orbis Electric has delivered more than a product. They’ve delivered a platform that can help the world move—literally and figuratively—towards a cleaner, more efficient future.