Advanced Cutting Systems Are Transforming Civil Engineering

Roadbuilding in 2025 is no longer just about pouring concrete and rolling asphalt. Civil engineers face growing pressure to deliver infrastructure that lasts longer, costs less, and minimizes its environmental footprint.

From highways that must handle heavier freight traffic to bridges that demand pinpoint precision in prefabrication, the challenges are expanding in both scale and complexity. Traditional cutting tools are struggling to keep up.

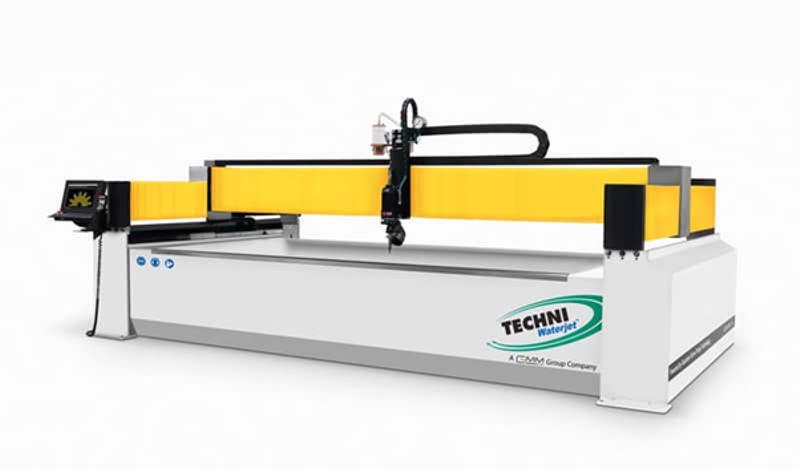

This is where advanced cutting systems come into play. Among them, waterjet technology has become one of the most versatile and effective solutions for modern infrastructure. Contractors increasingly rely on advanced waterjet cutting machines by TECHNI Waterjet to handle the toughest materials while maintaining precision and efficiency on large-scale projects.

By enabling clean, precise cuts across a wide range of materials without the downsides of heat or vibration, waterjets are redefining how civil projects are built. In this guide, we’ll explore why smarter tools are essential, how they work, and what advantages they bring to the future of road construction.

What are advanced cutting systems in civil engineering?

Advanced cutting systems in civil engineering refer to specialized technologies designed to cut, shape, and modify tough materials used in infrastructure projects. These include waterjets, laser cutters, plasma cutters, and diamond wire saws. Unlike conventional saws or drills, they provide a higher degree of precision, efficiency, and safety, making them essential for projects that demand accuracy at scale.

Civil engineers use these systems to cut through concrete, asphalt, composites, steel reinforcement, and even natural stone. The versatility of these methods allows contractors to handle both prefabricated components in controlled environments and on-site adjustments during large-scale projects. Among all of these technologies, waterjets have gained particular attention for their ability to cut virtually any material without introducing heat or compromising structural integrity.

Why does road and infrastructure construction need smarter cutting tools?

The scale of today’s infrastructure projects has exposed the limits of older cutting techniques. Traditional tools like handheld saws, pneumatic drills, or thermal cutting systems are still used, but they often create more problems than they solve. For example, thermal cutting generates extreme heat, which can weaken or warp materials. Mechanical saws and drills produce vibration, dust, and significant wear on equipment, increasing costs and health risks for operators.

Beyond safety and material concerns, inefficiency remains one of the biggest drawbacks. Conventional cutting is slow, produces large amounts of waste, and often requires secondary finishing to meet project tolerances. In large highway or bridge projects, this translates into higher costs, longer timelines, and delays that ripple through supply chains.

Modern infrastructure also demands much more precision than before. Projects often involve prefabricated concrete segments, reinforced bridge decks, or composite materials that require exact dimensions to fit into place. Even a few millimeters of error can create cascading issues in assembly. This is why advanced cutting systems have moved from optional to essential. They provide cleaner, faster, and safer solutions that match the demands of 21st-century roadbuilding.

How does waterjet cutting work in civil engineering?

Waterjet cutting relies on a high-pressure stream of water, sometimes mixed with abrasive particles, to slice through tough materials. The process doesn’t rely on heat, which means no warping or weakening of structural elements. Instead, it uses focused kinetic energy to achieve clean, precise results.

The basic steps can be broken down as follows:

- Pressurization: Water is pressurized up to 60,000 psi or more.

- Mixing: Abrasives such as garnet are added for harder materials.

- Nozzle ejection: The high-pressure stream is released through a fine nozzle.

- Material cutting: The jet erodes the material layer by layer until the cut is complete.

Unlike thermal cutting, waterjets produce no heat-affected zone. This makes them particularly valuable for reinforced concrete, metals, and composites, where structural properties cannot be compromised.

What about other advanced cutting methods?

While water jet cutters are the most versatile, other systems are still widely used depending on project needs.

- Laser cutting: Excellent for thin metals and detailed cuts, but struggles with thick concrete or stone.

- Plasma cutting: Fast and effective for metals but generates heat and lower precision.

- Diamond wire cutting: Highly effective for reinforced concrete, though slower and less flexible.

Each method has its place, but when it comes to balancing versatility, safety, and precision, waterjets often stand out.

How are waterjets used in highway and road construction projects?

In civil engineering, waterjets prove their value by tackling a wide range of jobs. They are used to cut through concrete slabs during road rehabilitation, shape bridge components for prefabrication, and slice asphalt for resurfacing projects. Engineers also rely on them to cut guardrails, steel reinforcement bars, and even curbs and monuments made of stone.

Some real-world applications include:

- Cutting expansion joints in concrete highways

- Removing damaged asphalt sections without harming underlying layers

- Precision trimming of bridge deck components

- Shaping reinforced steel beams for infrastructure projects

This versatility is what makes them indispensable in large-scale civil engineering.

What materials in road construction can be cut with waterjets?

The adaptability of waterjet cutting is one of its strongest features. Unlike thermal or mechanical methods that are limited to specific materials, waterjets can handle virtually anything used in roadbuilding.

Common examples include:

- Concrete (reinforced and prestressed)

- Asphalt

- Steel and iron

- Aluminum and composites

- Stone (granite, limestone)

- Plastics and polymers used in infrastructure

This flexibility allows contractors to use a single tool across different phases of construction rather than switching between machines.

How precise is waterjet cutting for civil engineering?

Precision is critical in infrastructure, and waterjets deliver tolerances that rival many factory-grade systems.

What are the tolerances achievable with waterjet cutting in infrastructure projects?

Typical kerf widths range from 0.5–1.2 mm. Depending on the thickness and material, tolerances can be as tight as ±0.1 mm, with most civil projects working within ±1.0 mm. Compared with other systems:

- Laser cutting: tighter tolerances on thin metals, limited on thick materials

- Plasma cutting: faster but less precise

- Diamond wire cutting: accurate but slow

This makes waterjets ideal for prefabrication, where large elements must fit seamlessly on-site.

How thick of materials can waterjets cut in roadbuilding?

In practice, waterjets can cut:

- Up to 12 inches (300 mm) of steel

- Over 24 inches (600 mm) of softer materials like concrete or stone

Such ranges are unmatched by most competing technologies, reinforcing waterjets’ position as the go-to for road construction.

What are the main advantages of waterjet cutting for civil engineering?

Engineers value waterjets for several reasons:

- No heat distortion

- Cuts virtually any material

- High precision on large-scale elements

- Reduced waste and environmental impact

- Safer working conditions

- Faster turnaround for prefabrication

The combination of performance and safety makes them particularly appealing for long-term infrastructure projects.

How do smarter tools reduce waste and improve efficiency in road projects?

Every cubic meter of wasted material or reworked component costs time and money. Waterjets and other advanced tools optimize efficiency by producing precise cuts and minimizing material loss.

Some key strategies include:

- Optimized nesting of parts to reduce scrap

- Minimal kerf width, saving material

- Selective demolition that removes only damaged sections

This leaner approach supports sustainability while also lowering overall project costs.

What industries and civil engineering sectors benefit from advanced cutting?

These technologies extend far beyond highways. Civil sectors making strong use of advanced cutting include:

- Highway and bridge construction

- Tunneling and underground transport

- Airports and runways

- Rail infrastructure

- Prefabricated concrete plants

The ability to cut across multiple materials ensures wide applicability.

What should engineers consider before choosing a cutting system for infrastructure?

No single system fits every project. Engineers must weigh:

- Material thickness

- Type of reinforcement

- Precision vs speed needs

- Cost per cut vs lifecycle savings

- On-site mobility vs factory cutting

- Common mistakes such as underestimating reinforcement density in concrete

These considerations prevent costly errors and ensure the right tool is used for each scenario.

What are the best advanced cutting machines for civil engineering projects?

When selecting equipment, engineers often prioritize:

- Power and pressure capacity

- Mobility (truck or trailer-mounted for site use)

- Cutting head versatility

- Maintenance requirements

- Integration with CAD/CAM systems

Machines that excel in these areas help maximize uptime and flexibility.

What are the alternatives to waterjets in road construction?

Waterjets are not the only option. Engineers may still choose:

- Diamond saw cutting: traditional, but lower precision

- Wire saws: effective but slow and costly

- Plasma cutting: limited to metals

- Laser cutting: high precision, limited by thickness and reflectivity

These systems fill specific roles, but few match waterjets’ balance of performance and adaptability.

What is the future of cutting systems in civil engineering?

Emerging trends point toward automation, robotics, and AI-driven optimization. Future waterjets may integrate with digital twin models to plan cuts before materials reach the site. Sustainability will also play a growing role, with systems designed to recycle water and abrasives.

Smarter tools are set to transform how infrastructure is designed, built, and maintained.

A Stronger and Smarter Future

Civil engineering is moving toward a future where precision and sustainability matter as much as strength and scale. Advanced cutting systems — especially waterjets — are helping meet that demand by offering accuracy, safety, and versatility that traditional tools cannot match. From reducing waste to enabling complex prefabrication, these technologies are redefining roadbuilding for a new era.

The next generation of highways, bridges, and tunnels will not only be stronger but also smarter, thanks to the tools reshaping how we build them today.