Reinventing Steel for a Stronger, Lighter, Greener Future

Steel is the backbone of modern infrastructure, from soaring skyscrapers and bridges to the cars and trains that connect our cities. For over a century, engineers have relied on steel’s strength and durability to build the world around us. Today, this tried-and-true material is undergoing a remarkable transformation. A new generation of steel is emerging that promises to be stronger and lighter than before, while also being produced in ways that dramatically shrink its carbon footprint. In an era focused on sustainability and efficiency, next-generation steel is set to revolutionize construction and manufacturing.

This evolution of steel couldn’t come at a better time. The construction sector faces pressure to reduce material usage and cut CO₂ emissions, all without compromising structural safety. Traditional steelmaking is energy-intensive and emits significant carbon dioxide, about 7% of global emissions come from steel production. Meanwhile, architects and engineers are pushing the limits of design, demanding materials that are both high-performance and planet-friendly. In response, steel industry innovators and researchers have been “turning up the heat” on their old processes (in more ways than one) to deliver steel that meets these 21st-century needs. The result is a wave of breakthroughs, from advanced alloys and metal composites to fossil-free steel production methods, all poised to reshape the future of construction.

Stronger and Lighter by Design

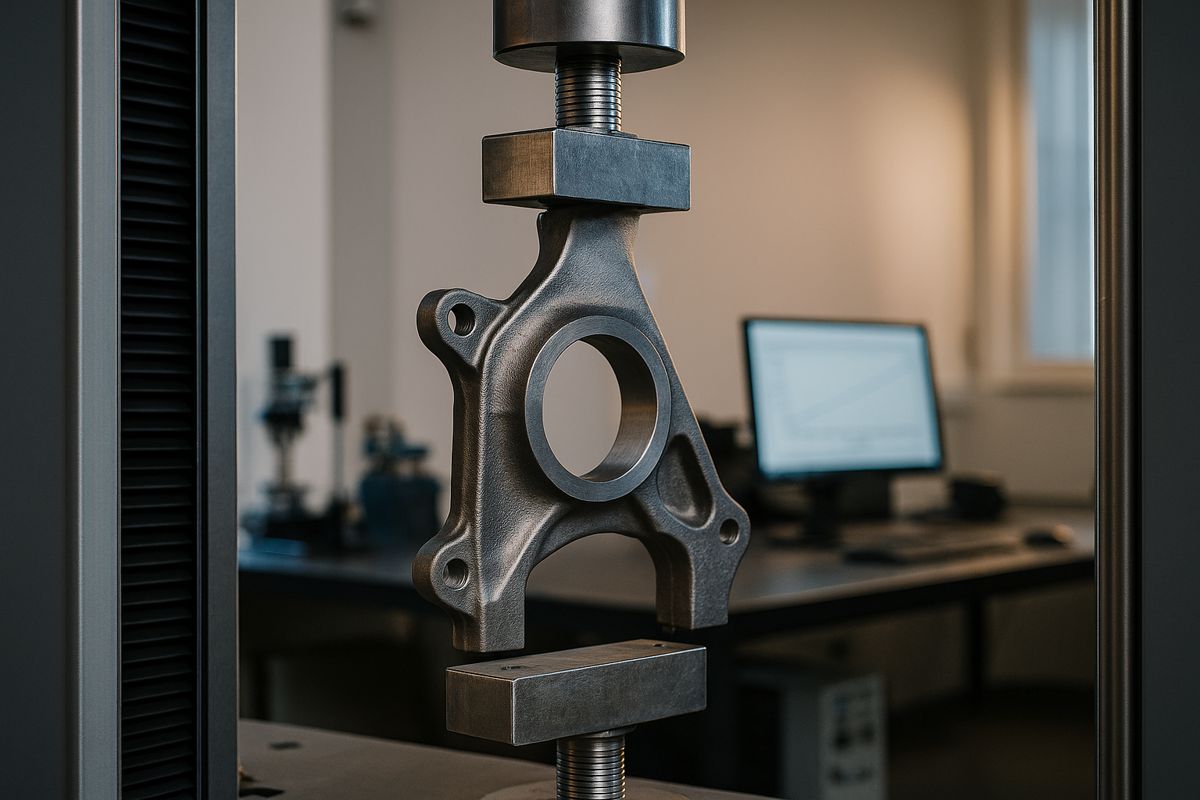

One of the most exciting developments in metallurgy is steel that is significantly stronger than conventional grades yet lighter in weight. High-strength steel isn’t entirely new, engineers have been incrementally improving steel’s strength for decades, but recent advances are taking it to another level. Advanced High-Strength Steels (AHSS), for instance, represent a new class of alloys originally pioneered for the automotive industry. These steels have exceptional tensile strength (often exceeding 1,000 MPa), allowing automakers to make lighter car frames without sacrificing safety. Now, similar concepts are moving into construction, where higher strength can translate into leaner structures and material savings.

Metallurgists are tweaking steel’s chemistry and microstructure to achieve these gains. They are adding elements like manganese, nickel, and even aluminium to create ultra-strong yet ductile alloys. A ground-breaking example comes from researchers in Germany and South Korea, who developed a lightweight stainless steel alloy with over 1 GPa (gigapascal) of strength and 17% lower density than typical stainless steel. By incorporating aluminium and carbon into the mix, they created a steel that is just as formable and corrosion-resistant as standard stainless, but with significantly less weight. In other words, they tackled the age-old trade-off between strength and weight head-on, and won. Such alloys could enable skyscrapers and long-span bridges to use thinner beams and columns, reducing overall mass without compromising performance.

Steel is also getting smarter through composite materials. By integrating steel with other high-performance materials, engineers can imbue steel components with new properties. For example, steel-carbon fibre composites marry steel’s rigidity with carbon fibre’s lightweight tensile strength. Ceramic-infused steel can enhance heat resistance for extreme environments, and polymer-coated steel adds flexibility and corrosion protection. These hybrid materials take the best of each component: the goal is a composite that’s tougher and lighter than plain steel, yet still cost-effective to manufacture. Aerospace and automotive firms have been early adopters, but construction could benefit too, imagine steel structural panels reinforced with carbon fibre, or rebar with polymer cores to prevent rust. As metallurgists note, such composites are engineered even at the molecular level to unlock unprecedented performance for critical structures.

Another fascinating innovation is metallic foam, essentially steel with internal air pockets that make it ultralight. Researchers have created composite metal foams that retain the strength of solid steel while dramatically reducing weight. In the image above, a cross-section of steel foam shows its bubble-like structure. These foams use hollow metal spheres or pores within a steel matrix to slash weight by up to 70%, yet they remain remarkably strong and shock-absorbing. In fact, one U.S. company claims its steel foam is “as strong as steel yet as lightweight as aluminium,” meaning an equal-sized bar of this foam can weigh the same as one made of aluminium. This material can also absorb impact and heat far better than solid metal, making it attractive for safety applications. While metal foams are still emerging tech, they highlight how creative engineers are getting in the quest for lighter steel. For the construction world, such lightweight yet strong materials could translate to easier handling, lower transportation costs, and structures that put less stress on foundations.

It’s not just about static strength either, self-healing steel is on the horizon. Inspired by self-healing concrete and polymers, scientists are experimenting with steel composites that can repair tiny cracks on their own. By embedding microcapsules of healing agents in the steel matrix, early prototypes have shown the ability to seal micro-cracks when stress or corrosion causes damage. It’s akin to giving steel a built-in maintenance crew. If perfected, self-healing metals could extend the lifespan of bridges, buildings and pipelines by automatically mending minor fractures, reducing the need for costly repairs. Though still largely in the research stage, this concept underscores how next-gen steel aims not only to be stronger and lighter, but also smarter and more resilient over time.

The Green Steel Revolution

Perhaps the most urgent transformation in steel is happening on the environmental front. Traditional steelmaking is a carbon-intensive process, for every ton of steel produced via blast furnace, roughly 1.8 to 2 tons of CO₂ are emitted. Given the millions of tons of steel produced globally, the sector’s carbon footprint is enormous. As climate change pressures mount, the steel industry has no choice but to reinvent itself with greener technologies. The good news is that a “green steel” revolution is well underway, targeting every stage of steel’s life cycle from production to recycling.

A cornerstone of sustainable steel is its recyclability. Unlike many materials, steel can be recycled infinitely without losing quality. Old steel beams or rebar can be melted down and turned into new steel products with no degradation in strength or durability. This has made steel one of the most recycled materials on the planet, in fact, over 25 billion tons of steel have been recycled in the past 125 years. Today’s structural steel is typically made with 92% recycled content on average, a figure that underscores steel’s role in the circular economy. Every scrap of steel that’s reused means less iron ore mined and less energy expended on extracting raw materials. For builders and developers, using recycled steel is a win-win: it often costs less than new steel (since it avoids the expense of mining and refining) and it contributes to green building certifications that reward high recycled content.

However, recycling alone won’t eliminate steel’s emissions, especially as demand for steel continues to grow. This is why the industry is pursuing major changes in how steel is made in the first place. The traditional route, the coal-fired blast furnace, is gradually giving way to electric furnaces and innovative iron-making methods that aim to cut out fossil fuels. One promising route is electric arc furnaces (EAF) powered by renewable electricity, which melt scrap steel to produce new steel. EAFs already account for about 40% of Europe’s steel production and generally emit far less CO₂ per ton than blast furnaces. The catch is that they rely on scrap availability and the resulting steel can have impurities, making it less suitable for certain high-grade applications. Even so, expanding EAF usage and improving scrap sorting can significantly green the supply.

The holy grail of green steel, though, is to make brand-new steel without coal at all. Enter hydrogen-based steelmaking. In conventional steelmaking, carbon (from coal or natural gas) is used to strip oxygen from iron ore in a chemical reaction, producing CO₂. If hydrogen is used instead, the by-product is plain water vapor, cutting out CO₂ entirely. This concept is being pioneered in projects like HYBRIT in Sweden and H2 Green Steel’s new plant in Boden, Sweden. These facilities use electrolysis (powered by wind, hydro, and solar energy) to generate green hydrogen, which then reduces the iron ore in a special reactor. The result is sponge iron that can be processed into steel with near-zero carbon emissions. Europe’s steelmakers are investing heavily in this shift, using hydrogen to close the roughly 1.3-ton CO₂ gap per ton of steel that blast furnaces currently produce. It’s an expensive transition (the EU estimates over €180 billion in investment needed to green its steel industry) but a game-changing one. By 2026, Sweden’s SSAB plans to supply commercial fossil-free steel, and companies like Volvo have already produced prototype vehicles using this steel.

Steel executives are framing this as nothing short of an industrial revolution. Martin Lindqvist, CEO of SSAB: “We are now taking a giant leap towards an entirely fossil-free value chain… We see a new green revolution emerging.” In August 2021, SSAB delivered the world’s first batch of hydrogen-reduced fossil-free steel to Volvo, a milestone that drew global attention. It demonstrated that heavy industries can collaborate to slash emissions in their supply chain without waiting for distant deadlines. As Lindqvist noted, it’s about tackling the entire value chain, from the mine to the end product, in pursuit of climate-neutral steel.

Another innovation cutting emissions is happening in the furnace itself. In Australia, engineer Veena Sahajwalla developed Polymer Injection Technology (PIT), which they nicknamed “Green Steel,” which replaces coal or coke with waste plastics and rubber in the steelmaking process. Old tires, plastic bottles and other polymer waste can serve as a carbon source to create foaming slag in electric arc furnaces, effectively upcycling trash into steel. This not only reduces reliance on coal but also helps solve the problem of plastic waste. By one estimate, using polymer injectants can cut a steel plant’s coke needs significantly, lowering its carbon emissions accordingly. Several steel mills have piloted this method, finding that it yields quality steel while consuming tons of otherwise landfilled material. It’s a compelling example of circular economy thinking, using one industry’s waste to fuel another’s production.

Of course, not all green steel solutions are high-tech. Some are as simple as rethinking logistics and energy efficiency. European steelmakers, for instance, are looking at sourcing iron ore locally to reduce the 3,500+ nautical miles journeys that iron shipments often take (and the CO₂ that those cargo ships emit). Others are optimizing their furnaces and power usage, even tweaking the oxygen mix in burners can make a difference in emissions. And there is interest in carbon capture at existing plants: capturing CO₂ from blast furnace exhaust and either storing it or using it in other industries. While carbon capture usage in steel is still minimal and adds cost, it could serve as a bridge technology for older plants until they can be replaced with cleaner setups.

The push for green steel is also coming from the top down. Policymakers in the EU and beyond are introducing stricter carbon regulations and incentives. The European Green Deal, for example, is prompting heavy industries to map out how they will reach net-zero emissions by 2050. In the United States, government infrastructure projects are increasingly expected to use low-carbon materials, and discussions of carbon border taxes (to penalize high-emission steel imports) are gaining traction.

Investors, too, are applying pressure through ESG (environmental, social, governance) criteria, meaning steel companies must show credible decarbonization plans to secure financing. The CEO of ArcelorMittal, the world’s second-largest steelmaker, recently highlighted the sector’s responsibility in this transition: “As a large emitter, the steel industry can make a vital contribution to achieving net zero by 2050. This project demonstrates what is achievable.”. Aditya Mittal’s comment came as ArcelorMittal announced a €1 billion investment to make its Sestao plant in Spain the world’s first full-scale zero carbon-emissions steel facility. The company aims to offer meaningful volumes of zero-carbon steel within a few years, a bold promise that signals how serious the industry’s biggest players are about this revolution.

Building the Next Era of Construction

What do these advances mean for construction professionals, investors, and policymakers? In short, a paradigm shift in how we design and build structures. Stronger, lighter steels give architects and engineers new freedom. Greener steels help developers and governments meet aggressive sustainability targets. And the combination promises buildings and infrastructure that are both high-performance and low-carbon, a dual benefit that was hard to imagine a generation ago.

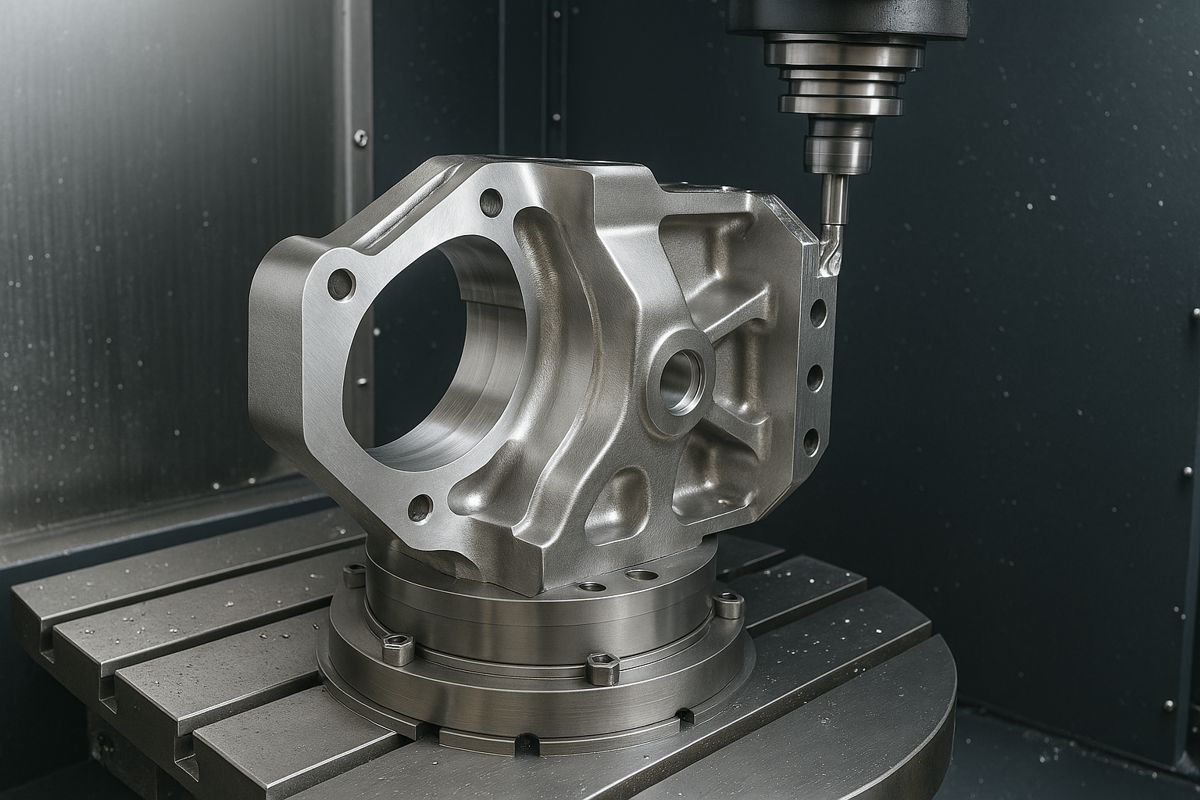

From an engineering perspective, higher-strength steels allow for bold designs with less material. Skyscrapers can reach taller heights with slimmer profiles when using steel that has, say, twice the yield strength of ordinary structural steel. Long-span roofs and bridges can be constructed with fewer supports, since the steel components can carry greater loads. Lighter steel also means reduced seismic forces (lighter buildings experience lower earthquake loads) and potentially smaller foundations, which can reduce construction costs. For project managers, using advanced steel might mean fewer tons of material to transport and lift into place, a significant logistical and economic advantage.

For example, a high-rise building designed with ultra-high-strength steel beams might use far fewer columns on lower floors, opening up floor plans while still supporting the weight above. Bridge builders using lightweight steel composites could erect spans that put less stress on pylons, or even explore modular construction where lighter steel modules are fabricated off-site and easily shipped to the project location. These are tangible benefits that can make construction faster and more efficient. In essence, next-gen steel is enabling a new era of “doing more with less”, more strength with less weight, more performance with fewer materials.

Equally important are the environmental and economic gains from green steel. Low-carbon and recycled steel can dramatically reduce a building’s embodied carbon, the emissions associated with materials and construction. This is crucial as many countries move toward zero-carbon buildings; operational energy efficiency is improving, so embodied carbon in materials is a growing piece of the emissions puzzle. Using greener steel is a direct way to shrink that footprint. It’s also increasingly a selling point. Environmentally conscious clients, from tech giants to city governments, are now asking for sustainable materials in their projects. A developer who can say their new office tower is made with “fossil-free steel” or 95% recycled steel gains a marketing edge and often regulatory goodwill.

There are also financial incentives aligning with these moves. Green building rating systems like LEED and BREEAM award points for using recycled and low-carbon materials, for instance, LEED credits require a certain percentage of recycled content in structural materials. Construction firms that adopt sustainable steel can attract eco-minded investors and meet government procurement requirements that favour low-emission suppliers. And as the cost of carbon is increasingly counted (through carbon pricing or taxes), using steel with a smaller carbon footprint could mean significant cost savings in the long run.

Let’s not overlook policy makers: they play a pivotal role in this transition. Governments can spur demand for next-gen steel by investing in public projects that specify “green steel” and by offering incentives or subsidies for low-carbon manufacturing. Some are already doing so. In Europe, alliances of producers and buyers are forming under initiatives like SteelZero, where organizations commit to buying 50% low-emission steel by 2030 and 100% net-zero steel by 2050.

By pooling purchasing power, these coalitions send a strong market signal that sustainable steel is the future. Similarly, ResponsibleSteel certification is emerging as a way to ensure steel coming into projects meets stringent environmental and social criteria. All this means that in the near future, being able to supply or work with next-generation steel could be a prerequisite for doing business in construction and infrastructure development.

In practical terms, how might a construction professional experience the next-generation steel revolution? Consider a scenario a few years from now:

- Bidding on a new project: The client asks for low-carbon materials to meet their sustainability pledge. A contractor sources green steel made via hydrogen reduction, which carries a product label showing its CO₂ per ton is 90% lower than normal. This choice helps win the bid.

- Design and engineering: The structural engineer selects high-strength steel sections (perhaps a grade twice as strong as standard steel), allowing smaller beam sizes. They also incorporate steel-composite elements, maybe steel beams with a carbon-fibre reinforced bottom flange, to maximize stiffness with minimal weight. The building’s frame ends up 20% lighter, saving on foundation costs.

- Construction phase: Workers find the lighter steel components easier to handle and assemble. Fewer heavy lifts are needed, and standard connections work thanks to thoughtful design integration. Despite the advanced materials, no exotic techniques are required on-site.

- Lifecycle and maintenance: The finished structure has lower embodied carbon from day one. Over its lifetime, it may benefit from steel elements that resist corrosion longer (thanks to alloys or coatings) and perhaps even heal minor cracks on their own if self-healing steel becomes viable. At the end of the building’s life, the steel components are 100% recyclable, ready to be melted down and used again in the next project, truly cradle-to-cradle.

This vision is quickly becoming reality. Each year brings new pilot projects and commercial launches that validate these technologies. We’ve already seen an electric arc furnace skyscraper in the U.S. built using almost entirely recycled steel. We’ve seen a bridge in the Netherlands fabricated with 3D-printed steel components, showcasing how digital manufacturing can further optimize material use. And we’ve seen automakers like Volvo and Mercedes-Benz sign deals for green steel, signalling that mass-market demand is on the way.

Forging a Sustainable Future

Steel has always been synonymous with progress, think of the Iron Age or the rise of the steel-framed skyline. Now, progress means making steel itself smarter and cleaner. The construction industry stands on the brink of a steel revolution where materials science and environmental responsibility go hand in hand. This next-generation steel isn’t just a laboratory curiosity; it’s arriving on factory floors and construction sites, driven by a global imperative to build more sustainably.

As the steel industry transforms, construction professionals will be among the biggest beneficiaries. They’ll have access to materials that enable daring designs previously thought impractical, from ultra-light roof structures to super-tall towers with lower embodied carbon than some mid-rise buildings today. Investors will find that supporting green steel innovation can unlock competitive advantages and fulfil ESG commitments. And policy makers will see that decarbonizing one of the hardest-to-abate industries is possible through innovation, regulation, and cross-sector collaboration.

Crucially, this is a story still being written. Challenges remain, new steel alloys must prove their long-term durability, green steel production needs to scale up and become cost-competitive, and the industry will need a skilled workforce to adopt unfamiliar materials and techniques. But the momentum is undeniable. With each new furnace retrofitted for hydrogen, each ton of CO₂ saved by recycling, and each structure optimized with stronger steel, we forge a path toward a construction landscape that is efficient, cutting-edge, and aligned with our climate goals.

The pioneers driving these changes often invoke a simple idea: the best way to predict the future is to create it. In mills and research labs around the world, they are creating the future of steel right now. It’s a future where skylines rise higher on the shoulders of advanced alloys, where our infrastructure leaves a lighter footprint on the earth, and where even the hardest metal can be a symbol of sustainability.

For the construction sector and beyond, that is an inspiring vision, one that is becoming reality with every new innovation in stronger, lighter, greener steel.