Nanotech Is Transforming Rubber‑Reinforced Mixes for Green Concrete

Concrete may be the backbone of global infrastructure, yet the world is grappling with its environmental footprint. Traditional mixes rely heavily on virgin aggregates and cement, both major contributors to resource depletion and carbon emissions. As nations push toward cleaner construction, researchers and engineers are increasingly searching for clever ways to improve performance while cutting environmental impact.

Among the most promising developments sits a compelling blend of waste-rubber recycling and nanotechnology. Rubber aggregates sourced from end-of-life tyres and nano titanium dioxide are emerging as a dynamic duo in sustainable concrete research. This hybrid approach not only diverts waste from landfill and reduces the strain on natural sand resources, but also tackles the well-known performance limitations of rubberised concrete.

And make no mistake, those limitations have long been a sticking point. When crumb rubber replaces fine aggregates in traditional mixes, fresh and hardened concrete properties tend to decline significantly. Reduced density, compromised workability and noticeable drops in compressive, tensile and flexural strength all historically plagued rubber-reinforced concrete. Yet researchers at the National Institute of Technology, Hamirpur, India, have demonstrated that these drawbacks are far from insurmountable.

Digging into the research

Civil engineering scholars Jatin Sharma, Gyanendra Kumar Chaturvedy and Umesh Kumar Pandey undertook a detailed study titled Sustainable Rubberized Concrete: The Role of Nanotitanium Dioxide in Enhancing Mechanical and Durability Properties. Their goal focused on evaluating whether finely dispersed nano titanium dioxide could offset the structural penalties associated with rubber aggregates.

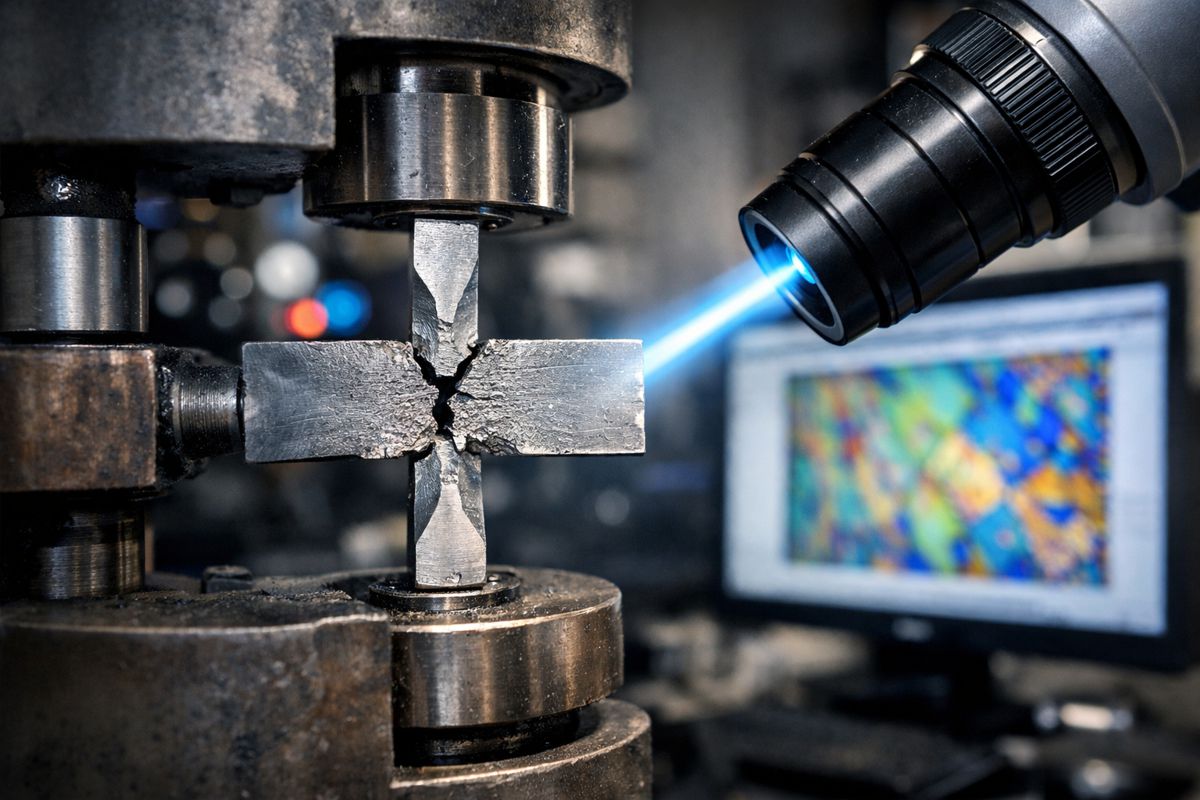

The team developed M40-grade mixes aligned with IS 10262:2019 and replaced fine aggregates with crumb rubber at 5, 10 and 15 percent. Ordinary Portland Cement was partially substituted with nano titanium dioxide at 0.5, 1 and 1.5 percent. The blend was then subjected to an extensive battery of laboratory tests, including slump, density, ultrasonic pulse velocity, rebound hammer assessments, compressive and tensile strength, flexural analysis and durability testing under acid exposure. High-temperature behaviour up to 600 degrees Celsius and microstructural analysis using field emission scanning electron microscopy added even more depth to the investigation.

The results were striking. Not only did nano titanium dioxide improve early-age hydration, helping densify the interfacial transition zone, but the modified mixes showed meaningful gains in strength and durability. The rubber-only mixes saw sharp reductions in mechanical performance at higher replacement levels. However, the addition of one percent nano titanium dioxide produced a nearly 20 percent increase in compressive strength at 28 days compared with the same rubberised mix without nanomodification. At 90 days, the R5-NT1 trial achieved an impressive 56.32 megapascals.

Crack resistance, flexural strength and tensile capacity also saw material improvements, with increases of more than 15 percent in some cases. Durability indicators pointed in the same direction. Sorptivity dropped, chloride ion penetration fell by roughly half and acid-attack mass loss improved. When exposed to high temperatures, nano-enhanced samples retained more residual compressive strength, hinting at better fire-resilience characteristics.

Sustainability and economics

It is tempting to assume that performance gains alone justify material innovation, but cost and environmental impact remain core considerations for the industry. A noteworthy aspect of this study involved life-cycle analysis and economic evaluation. Although incorporating nano titanium dioxide introduces a marginal increase in embodied energy and carbon emissions, the recycling benefit from rubber aggregates provides a substantial environmental offset.

Equally important, the economic case appears sound. While nano additives slightly elevate upfront material costs, the long-term gains in durability and service life deliver lifecycle value. For asset owners, contractors and public bodies driving sustainable development agendas, durability translates directly into reduced repair cycles, fewer disruptions and better value for money.

Global research context

The Hamirpur findings align with a growing body of international research. Universities and laboratories worldwide are exploring nanomaterial enhancement in concrete, including nano silica, nano clay and graphene-based additives. Nano titanium dioxide is particularly appealing due to its photocatalytic properties, self-cleaning performance and capacity to improve microstructural packing.

Studies published by institutions in Canada, Malaysia and Europe have reported similar performance trends, especially around compressive strength improvement and permeability reduction. Meanwhile, tyre-derived crumb rubber has attracted interest in highway pavements, noise-reducing barriers and impact-resistant structural elements, given its elasticity and energy-absorbing behaviour.

Testing methods that matter

The project’s rigorous methodology deserves attention from policy makers and engineering leaders. Beyond mechanical testing, the use of response surface methodology and analysis of variance provided statistically robust insight into interactions between rubber content and nano additive dosage. This approach helps future researchers and practitioners optimise proportions for different performance targets.

FESEM imagery, meanwhile, confirmed a refined pore structure and denser cementitious matrix in nano-modified mixes. This micro-scale densification underpins the improvements in physical behaviour, highlighting how unseen chemical and particle-level changes can dramatically influence large-scale structural outcomes.

What this means for industry

It is increasingly clear that sustainable construction materials cannot simply be judged on one metric. Rubber-modified concrete supported by nano titanium dioxide creates a route to:

- Divert large volumes of waste tyres from landfill

- Reduce dependence on natural sand resources

- Achieve meaningful improvements in strength and durability

- Improve long-term asset performance

- Maintain economic feasibility

Although further field-scale validation is needed, early indications point toward viable use cases in transportation infrastructure, industrial flooring, precast elements and even structural components with appropriate design guidance.

Professionals across the sector are watching with interest. As one academic editorial on green concrete innovation notes: “The challenge is no longer whether sustainable concrete can perform, but how quickly the industry can adopt high-performance alternatives at scale.”

Concrete technology for a new era

Innovation in materials rarely emerges overnight, yet momentum is clearly building. The convergence of recycling, nanoscience and structural engineering is shifting concrete technology into a new era. The Hamirpur research strengthens the argument that smart additives can unlock the full potential of alternative aggregates.

A future where infrastructure is both resilient and responsible is steadily taking shape. With science, industry input and bold engineering practice working hand-in-hand, sustainable concrete solutions are no longer fringe experiments but serious candidates for mainstream deployment.

Sustainable rubberised concrete enhanced with nano titanium dioxide shows that greener building materials can deliver better performance at the same time. It is a powerful reminder that environmental responsibility and engineering excellence are not mutually exclusive

In a world demanding lower carbon structures and longer-lasting infrastructure, this breakthrough offers a welcome glimpse of what is possible when innovation leads the mix.