Harmony Building a Strategic Copper Future with Metso in Queensland

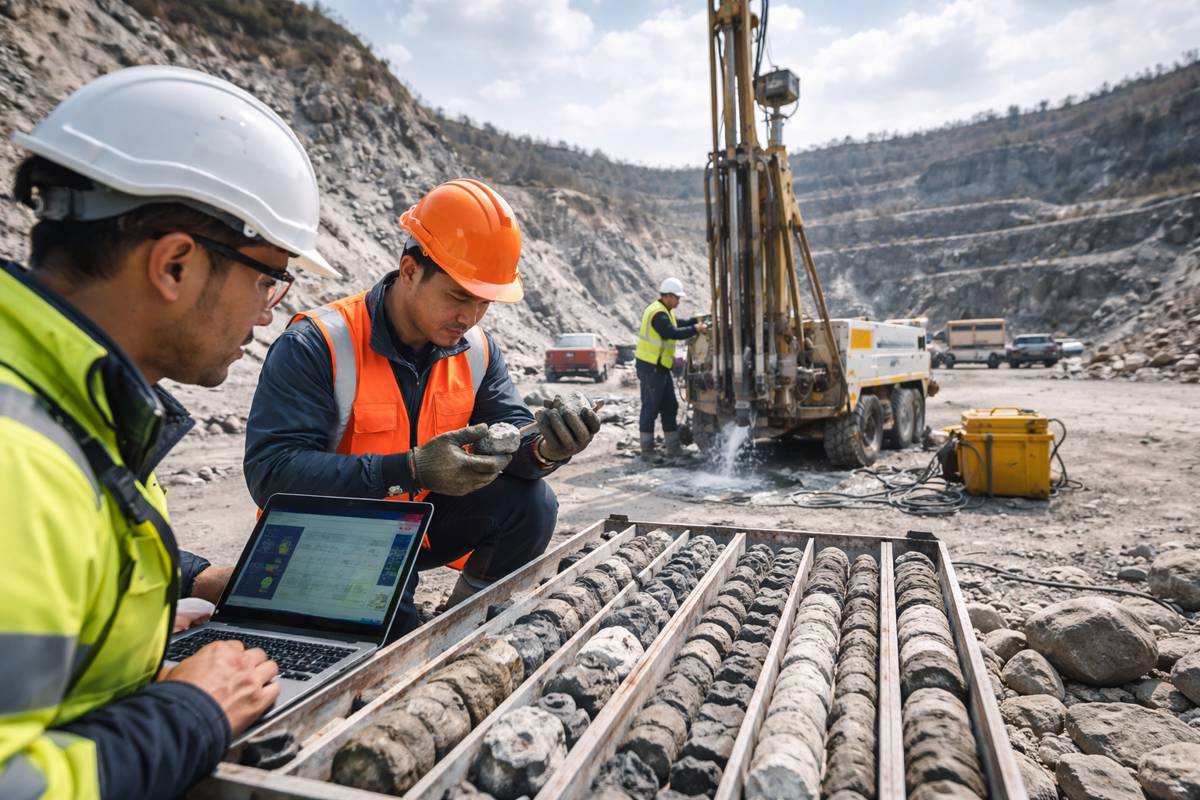

Harmony has awarded Metso a significant order to supply the key process equipment for the Eva Copper Mine Project in Queensland, marking one of the most important greenfield copper concentrator developments in Australia in more than a decade. The mine is central to strengthening Australia’s long‑term supply of critical metals used in electrification, clean energy systems and advanced manufacturing.

The order is valued at approximately EUR 55 million and has been recorded in the Minerals segment’s third‑quarter 2025 results. The investment highlights the scale and strategic nature of the project, particularly at a time when global demand for copper continues to rise due to renewable energy deployment, electric vehicle manufacturing and the construction of modern transmission networks.

Kai Rönnberg, Vice President, Minerals, Asia Pacific at Metso, expressed his enthusiasm for the partnership: “We are extremely proud to have been chosen by Harmony. From initial sample testwork at our Perth Technology Centre to optimizing the equipment selection, it’s been a pleasure to collaborate with Harmony on this project. Even more exciting is the long‑term partnership to ensure successful equipment delivery and lowest total cost of ownership during operations.”

Why the Eva Copper Mine Matters

Copper is rapidly evolving into one of the world’s most strategically important minerals. The International Energy Agency forecasts that global demand for copper may double by 2040 as electrification accelerates. Renewable energy projects, high‑capacity transmission networks, smart grids, offshore wind farms and the increasing adoption of electric vehicles all rely heavily on copper due to its superior conductivity and durability.

Australia has long been considered one of the world’s most resource‑rich jurisdictions, and the Eva Copper Mine Project strengthens its role as a secure supplier of forward‑facing metals. The Queensland location provides both logistical benefits and access to established mining communities with highly skilled workforces.

Industry analysts note that greenfield concentrators of this scale have become less frequent in Australia over the past decade. Rising development costs, increasing technical complexity and environmental regulations have made new concentrator builds more challenging. Harmony’s investment therefore sends a strong signal that forward‑looking metals remain central to Australia’s economic future.

Advanced Technologies for Efficient Mineral Processing

Metso will deliver a range of high‑performance mineral processing technologies designed to ensure reliable operation, optimised throughput and long‑term serviceability.

Equipment includes:

- A gearless Premier SAG mill with 24MW installed power

- A twin pinion Premier ball mill with 18MW of installed power

- Mill linings and essential spare parts

For pebble crushing, Harmony has selected two MP800 cone crushers, known for their durability, efficiency and consistent performance in demanding mining environments. These crushers are widely recognised for their ability to maintain throughput under variable ore conditions.

The project’s flotation circuit is substantial and will feature 15 Metso TankCell flotation cells and a Vertimill VTM3000. TankCell technology has gained a strong reputation across global copper operations for its proven metallurgical performance, reduced operational risk and optimised power consumption.

The slurry circuit will adopt real‑time process monitoring tools, including a Metso Courier 6X SL slurry analyser that provides continuous assaying of copper and associated minerals. A Metso PSI 500i particle size analyser coupled with Metso MillSense technology will allow rapid online analysis of grinding performance, leading to tighter process control and reduced energy losses.

Water Recovery, Tailings Management and Sustainability

Harmony has also selected substantial concentrate and tailings management solutions, including a 20‑metre concentrate thickener and a 65‑metre tailings thickener. Both will include Reactorwell technology, designed to reduce flocculant usage and enhance water recovery.

Reactorwell systems have been increasingly adopted in modern concentrators where water scarcity, regulatory expectations and social licence considerations are more stringent. Mining operators are now expected to demonstrate improved water stewardship, reduced tailings risk and smarter resource utilisation.

The Eva Copper Mine will also deploy a fully automated Larox PF filter to produce a dry, homogenous concentrate product. Dry filtration has become a preferred method in many copper operations because it reduces the moisture content of concentrate, simplifies transport and improves material consistency for downstream processes.

The majority of the supplied equipment forms part of the Metso Plus portfolio, which focuses on reliability, maintainability and total lifecycle cost efficiency.

Local Support and Service Agreements

In addition to the equipment contract, Metso and Harmony have agreed a multi‑year major goods support arrangement. The agreement will help ensure smooth commissioning, efficient ramp‑up and long‑term performance of the concentrator.

Service technicians will provide local support both on site in Queensland and through Metso’s extensive Australian service centres and spare parts facilities. This network is designed to provide rapid response capability, secure parts availability and reliable operational continuity.

Rönnberg highlighted the strength of the collaboration: “In addition to the equipment delivery, Metso and Harmony have agreed a term sheet for a multi‑year major goods support agreement. This will ensure smooth commissioning and ramp‑up of the Eva Copper concentrator plant. Local service support will be delivered both on site and through Metso’s Australian service centres and spare parts facilities, ensuring fast response times and operational continuity throughout the project lifecycle.”

A Global Leader in Process Innovation

Metso is widely recognised as a leading provider of sustainable technologies and process optimisation services for the aggregates, minerals processing and metals refining sectors. Its portfolio is designed to improve energy efficiency, reduce water consumption, maximise output and minimise environmental risk.

The company has a strong reputation for digital process control, integrated monitoring tools and detailed lifecycle service support. The use of online particle size analysers, smart mill technologies and continuous slurry monitoring demonstrates how digitalisation is reshaping concentrator performance.

Beyond copper, Metso technologies are used across gold, iron ore, nickel, lithium, platinum group metals and other industrial minerals. The growing adoption of Vertimill energy‑efficient grinding and TankCell flotation across major mines reflects a shift towards lower‑carbon process flowsheets.

Headquartered in Espoo, Finland, Metso employs nearly 17,000 people across around 50 countries. The company reported EUR 4.9 billion in sales at the end of 2024 and is publicly listed on Nasdaq Helsinki.

Cleaner, Smarter and Technically Advanced Project Delivery

The Eva Copper Mine Project represents both a major technical opportunity and a strategic commitment to sustainable mining in Australia. Metso’s integrated equipment, digital analysis systems and robust service network offer Harmony a reliable pathway to efficient concentrator performance, reduced operational risk and improved long‑term value.

As the demand for copper continues to rise, forward‑thinking mine developers are exploring cleaner, smarter and more technically advanced project delivery models. Harmony’s investment at Eva demonstrates confidence in modern mineral processing, local capability and the wider future of responsible metals supply.