Enoba workflow monitoring solutions are help construction sites stay on schedule

Many construction sites are not able to finish their projects on time and staying within budget and on schedule is extremely challenging. Poor site supervision and poor site conditions are among the most common causes of delay. Enoba Smart Construction, an EIT Digital-supported innovation activity within the Digital Industry focus area, is providing holistic solutions to automatically monitor workflows and tasks at construction sites, making it easier for managers to keep track of what’s happening and improve their performances.

“With our solutions all the data coming from different sources is easily accessible, whereas often it is partitioned into silos and managed by dedicated apps and software,” Enoba’s CEO Marco Hirsch says.

To achieve this, Enoba uses and provides open interfaces to integrate existing data coming from different information sources.

Enoba’s integrated hardware and software platform consists of a network of different sensor nodes which collect a variety of relevant onsite data, ranging from ordinary noise, weight, shock, temperature or humidity measures to more complex information, regarding, for instance, the chemical composition of the air.

All information is fed in real time into a dashboard where it can be viewed live by the respective stakeholders (e.g. the project manager). AI algorithms are used to aid drivers and managers in taking decisions on and off site.

The activity was launched in 2018 and, as part of the business plan, a spin-off by the same name, Enoba, was created by activity leader DFKI, the German Research Center for Artificial Intelligence.

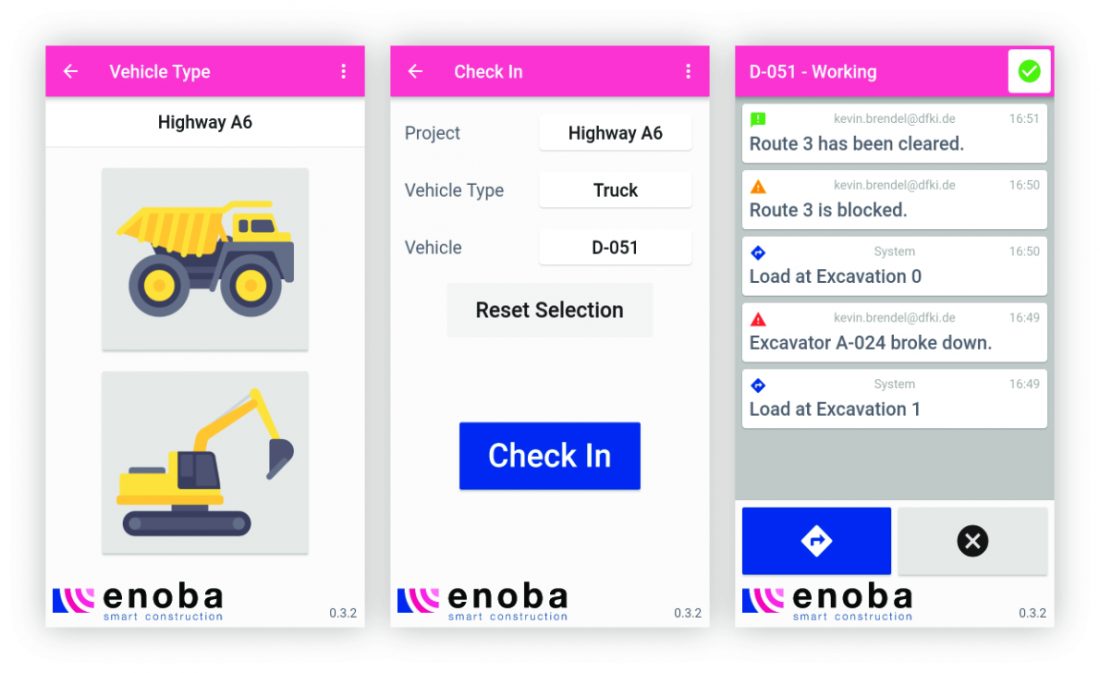

As first members of the Enoba ecosystem, Enoba Drive and Enoba Manage work together to improve the efficiency of earth-moving operations and prototypes are currently being tested at a partner’s highway constructions site.

In this specific use case, Enoba has equipped the trucks’ and excavators’ drivers with smartphones and the Enoba Drive App that tracks where machines are located and what they are doing.

In addition, information about the load and the surroundings of the trucks is gathered by the sensors.

“We chose the very specific use case of construction sites to enter the market because of their huge potential in terms of savings, and also because it was feasible to complete the prototyping within the time frame of the innovation activity. But we are already extending the same technology for very different use cases,” says Hirsch.

Partners of the Enoba Smart Construction innovation activity include Ferrovial Agroman, Ci3, DFKI and FBK.

Enoba’s services also include consulting on the use of innovative technologies and methods of AI in construction and contract development to solve specific challenges in customers’ projects.