Material-wise the most sustainable building material is wood

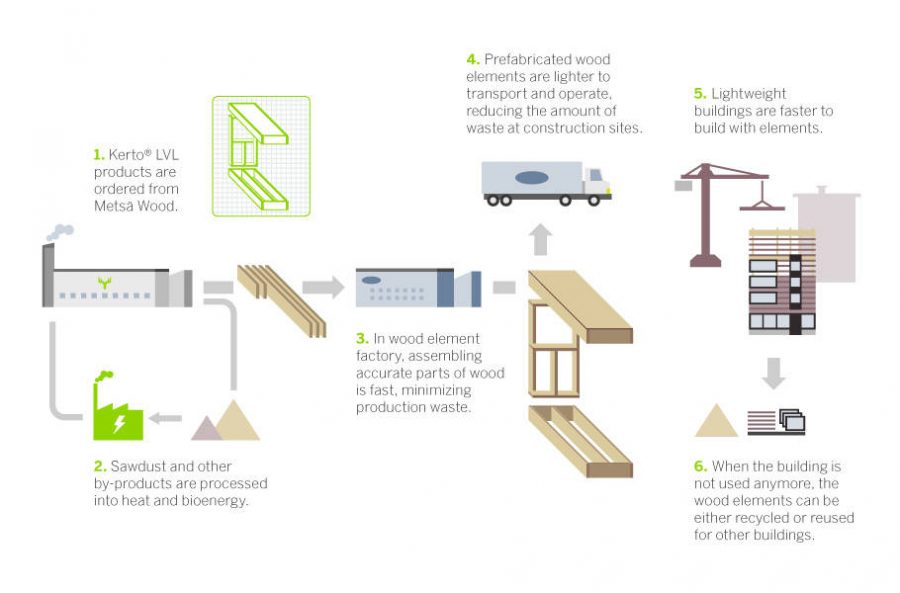

The construction sector continues consuming globally around one third of the planet’s already limited resources. Building with wood products like Kerto® LVL (laminated veneer lumber) enables the vitally important change towards Material-wise sustainable building.

“Our planet cannot keep up with our consumption. We use materials faster than the Earth can produce new ones. We generate more waste than the Earth is able to absorb,” Matti Kuittinen, architect and researcher from Aalto University, points out.

Within the building materials sector, the production of steel and aluminum alone require around 51% and concrete production 17% of the energy for producing all building materials globally.

“We need a shift from unsustainable consumption patterns without delay. Increasing the use of sustainably sourced wood in construction is a much-needed step in the right direction. As a co-benefit, non-renewable raw materials such as steel and cement, can be saved or used for more value-added purposes,” says architect Kristoffer Tejlgaard from Atelier Kristoffer Tejlgaard.

Building with wood is material-wise

With the highest strength, wood is so light that buildings can be built with less sturdy foundations, which in turn requires less piling, construction materials and time. Replacing other frame materials with wood could improve the material efficiency of a building considerably. According to recent studies, timber-framed building is the most material efficient alternative, followed by light-gauge steel frame.

“When the frame is light, co-benefits are achieved along the whole production and construction chain: the emissions created by manufacturing and transportation are smaller, and less energy is required for lifting the components at the building site. Lightness also enables a high degree of prefabrication as building elements and modules or even entire buildings can be manufactured off-site and transported to their final location. Time, money as well as environment is saved,” states CEO Ruben Dahl Hansen from Arca Nova Bolig AS.