Haver and Boecker Niagara introduces PROcheck to improve screening performance

Haver & Boecker Niagara’s new mineral processing brand, introduces PROcheck, a service program dedicated to keeping customers’ operations running at peak performance.

Each analysis comes complete with a thorough vibrating screen and screen media inspection report — known as a PROcheck — and focuses on recommendations for optimized screening. The program is complemented by Haver & Boecker Niagara’s Pulse Vibration Analysis to help customers maximize productivity, proficiency and profits.

Haver & Boecker Niagara highlighted its signature PROcheck service program during CONEXPO-CON/AGG 2020.

“By partnering with our customers through the PROcheck service program, we are monitoring the efficiency of their screening process to identify potential problems early on,” said Karen Thompson, president of Haver & Boecker Niagara’s North American and Australian operations. “The program can significantly extend service intervals, improve vibrating screen and periphery equipment performance and, most importantly, save our customers time and money.”

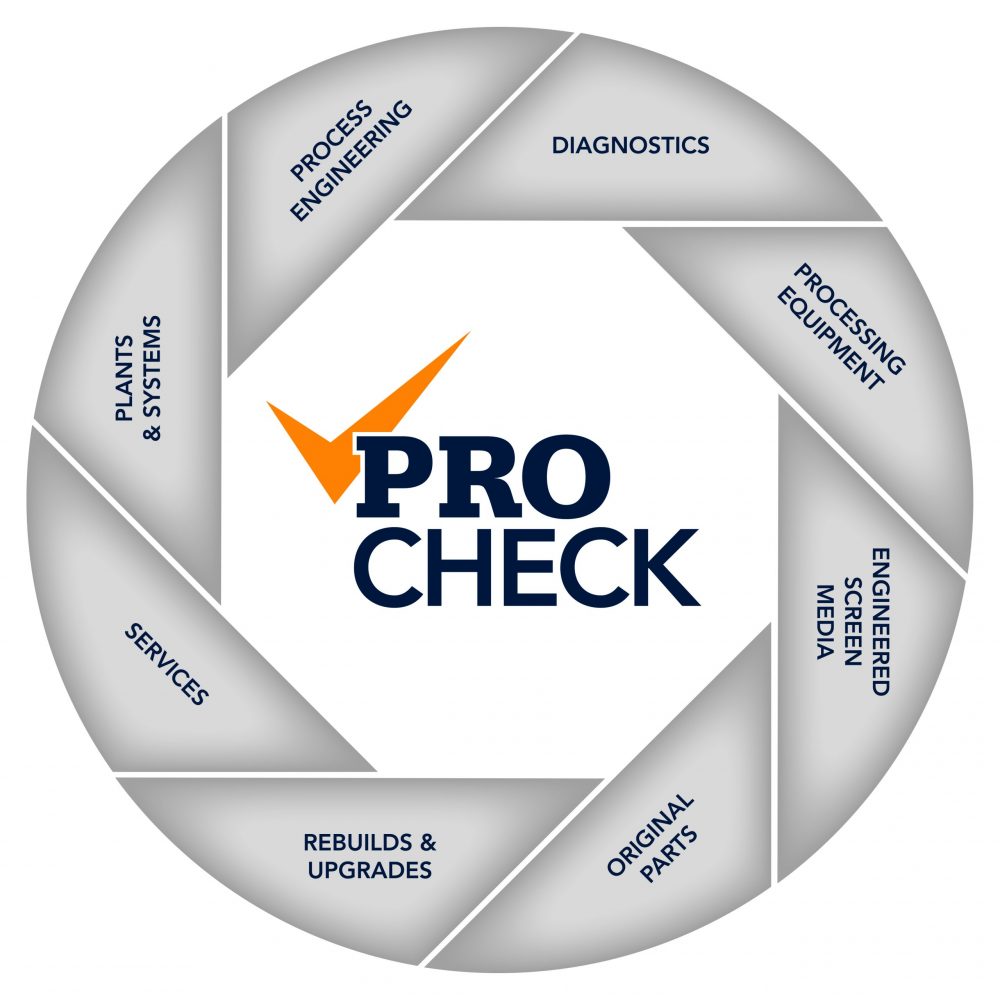

PROcheck applies Haver & Boecker Niagara’s expertise in diagnostics, processing equipment, engineered screen media, original parts, rebuilds and upgrades, services, plants and process engineering to inspect customers’ screening processes in order to recommend best practices for processing proficiency. An evaluation can be completed quickly, and, if necessary, even while equipment is operating.

“We are experts at looking at the big picture,” Thompson said. “We engineer and manufacture both vibrating screens and screen media, and we have developed our own diagnostics system, Pulse Vibration Analysis. This gives us the insight to offer valuable advice producers won’t find elsewhere.”

All observations and recommendations are recorded in a comprehensive report that is available before the Haver & Boecker Niagara representative leaves the site.

Haver & Boecker Niagara is a leading provider in screening, washing, pelletizing and primary crushing systems. The company’s mission is to deliver the best of these technologies to customers in the aggregates, mining, minerals, cement, chemical and food industries. With deep roots and years of experience in these industries, Haver & Boecker Niagara uses its innovative and shared technologies to effectively meet the needs of customers around the world.