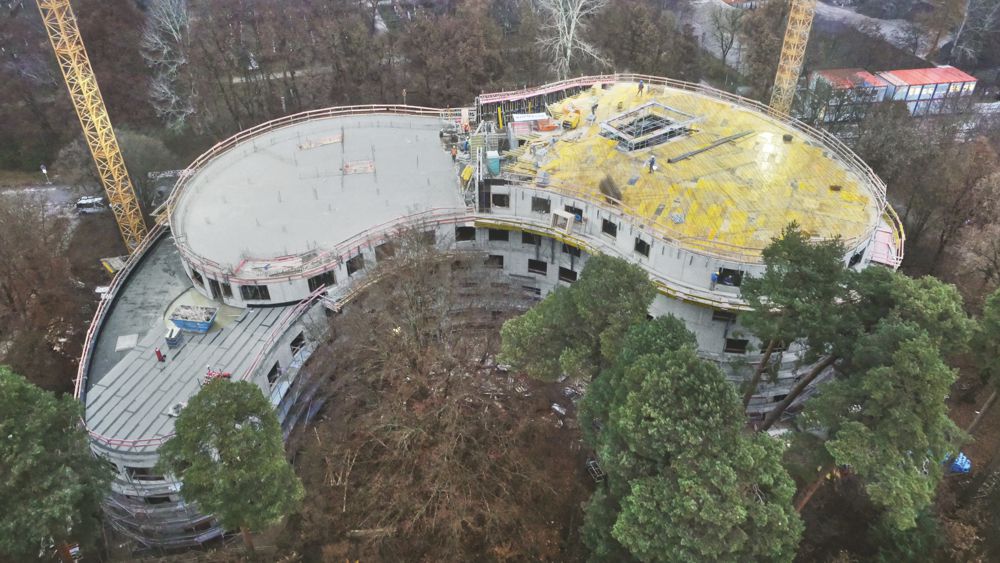

Unusual geometry formwork delivers curves, corners and edges

Unusual geometry and best-time progress: formworking operations 50 % faster and commissioning quantities lower on the AWO-Föhrenpark retirement home project.

The ‘Arbeiterwohlfahrt’, (workers’ welfare association, AWO) has commissioned a new retirement home in the south-west of Bavaria’s capital city, Munich. Formwork know-how from Doka is contributing to smooth progress on the build. Concremote concrete sensor technology has made formworking operations twice as fast as originally planned. And the commissioning quantity of equipment on site for floor slabbing is reduced by one third.

Not one single right angle, not one single straight exterior wall – the building envelope of the AWO-Föhrenpark retirement home consists entirely of curves. With approximately 12,000 m2 of floor area, the retirement home and care centre built to a design by the sorge . architekten GmbH company nestles amoeba-like among the surrounding trees in perfect harmony with nature. A preservation order protects the old-growth trees at the wooded location, so the uniquely organic shape of the structure was chosen as the perfect fit for development of this site. The six-storey retirement home will cater for slightly more than 130 residents. After one and a half years of construction it is scheduled for completion by the end of 2017. Construction work is in the capable hands of Zechbau GmbH’s Munich branch and Bauunternehmung Glöckle SF-Bau GmbH from Schweinfurt.

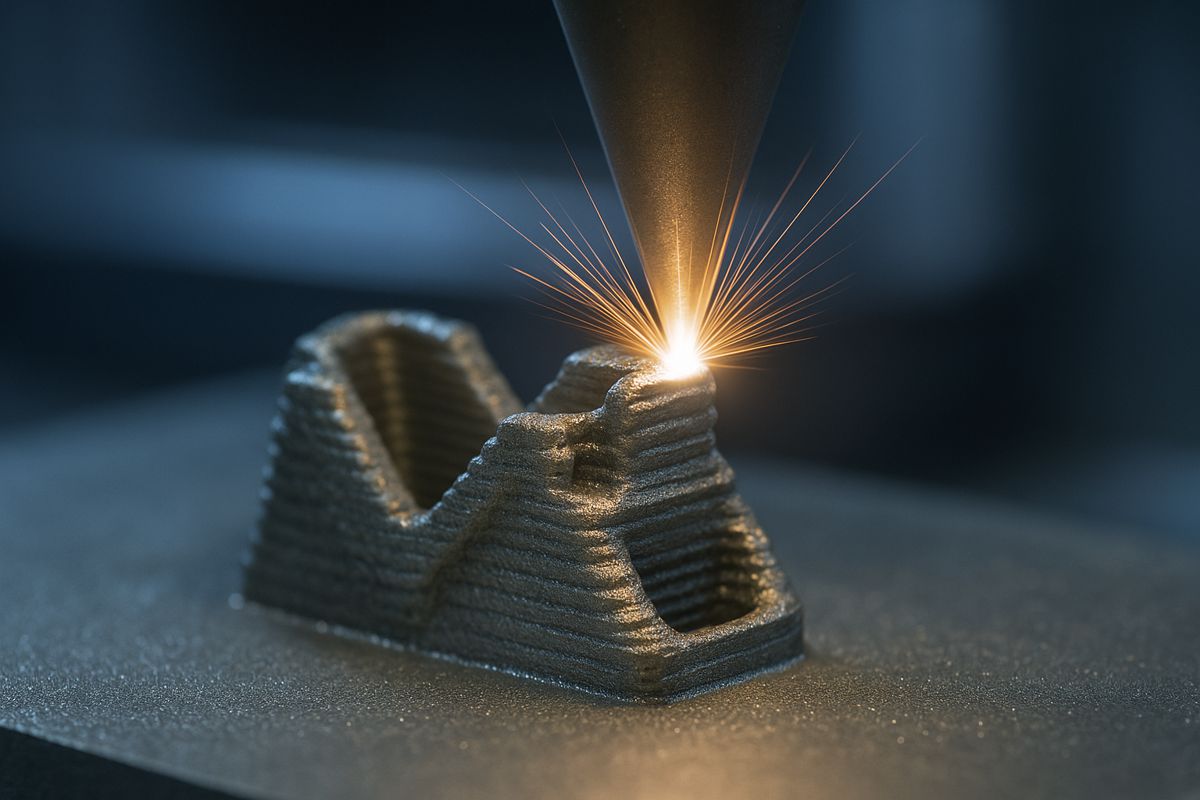

High-speed forming with Concremote

Concremote delivers real-time data on temperature and strength development in fresh concrete. Here on the AWO-Föhrenpark build this digital concrete sensor technology has proved a tremendous driver for the formworking operations. Three Concremote slab sensors are in use, with the result that a three-day cycle can be achieved and maintained. “Concremote has significantly boosted productivity on the jobsite. Our team knows exactly when the concrete has reached its target strength, so they can always go right ahead and strike the formwork at the earliest possible time. And our commissioning quantity on site is reduced by one third. As well as that, Concremote gives us more certainty in our verification for the project”, states Project Manager Tillmann Bayer from Zechbau GmbH.

The sensor is pressed into the fresh concrete as soon as it has been screeded. The sensor’s job is to measure temperature at regular intervals, so that strength development can be calculated. The authorised site managers can call up these data through a secure web portal at any time with a notebook, tablet PC or smartphone.

So the ARGE Föhrenpark consortium’s site crew can start early stripping after only two to three days. The upshot is that the floor-slab formwork is ready for the next cycle all the sooner. At the same time, the Concremote measurements also help the engineers decide on the ideal time for switching from the summer to the winter formula for the concrete. On the AWO-Föhrenpark project, that meant commissioning quantities could be reduced by 600 m2 of formwork per storey. And with fewer materials, formworking operations were speeded up by 6 whole weeks. That works out at a savings potential somewhere in six figures.

The formwork solution from Doka: great all round

With 54 different radii in all, variations in storey height and abrupt changes in levels on a single storey, the formwork for the walls of the AWO-Föhrenpark retirement home is certainly not of the common or garden variety. So the Doka engineers developed a perfect-fit formwork concept specifically for these requirements.

A combination of Circular formwork H20 with Framed formwork Framax Xlife and Column formwork KS Xlife does the trick. The pre-assembled panels of the circular formwork are operated by spindles, so they adapt quickly and easily to whichever radius is needed. This variability is a vital benefit on this build, because there are nine changes in radius on every floor. Special bending templates make the adaptations all the easier.

Circular formwork H20 also enables the ARGE Föhrenpark consortium’s site crew to gain the heights needed for the walls all the more rapidly. There are five panel heights and only one form tie is needed every 1.5 m2. So forming the different wall heights on each floor is fast and straightforward. The combination with Framed formwork Framax Xlife speeds up progress even more. The system scores with wide form-tie spacing and big gang-forms. Less crane time is needed for repositioning. With forming and stripping times shorter, Column formwork KS Xlife also contributes to faster concreting operations. This formwork features a special mechanism for easy opening and closing.

Timber-beam floor formwork Dokaflex 30 tec for the floor slabs helps minimise equipment costs and maintain speedy progress on the build. “Because of the unique geometry, on this project we knew we’d be dealing with many infill areas. Generally they are very time-consuming and generate high labour costs. But Dokaflex 30 tec is so adaptable that forming the complicated geometries of the AWO-Föhrenpark build was quick and easy. Permissible spacing between the floor props Dokaflex 30 tec is very wide, so we needed 30 % fewer props and work went ahead even faster”, says Ignaz Stegmann, foreman with Zechbau GmbH, summing up the advantages of the system. It’s all made possible by the high-strength I tec 20 composite formwork beam. Used as primary beam, it allows the floor props for Dokaflex 30 tec to be set at this wide spacing. This formwork system also offers easy solutions for downstand beams and closures.

Everything in its place

The curvatures and the variety of radii pose challenges for the site crew as regards correct positioning of the formwork. On each storey, 1,000 survey points are needed for precision positioning of the formwork panels. Each of these points is triangulated by tachymeter. This procedure and the high quality of the formwork combined make it possible to meet the strict statutory requirements for wall smoothness in structures of this kind. Five millimetres is the maximum permissible deviation.

Folding platform K, perfect scaffolding

Special solutions are also needed for the scaffolding. The structure is in very close proximity to the trees on this wooded site. There is not enough room for a conventional working scaffold. What works best on the AWO Föhrenpark jobsite is the Folding platform K. It offers self-supported working areas for speedy and – crucially – safe progress on the build. With a maximum load bearing capacity of 600 kg/m2, the scaffold platform enables safe and secure set-up and propping of the wall formwork.

All-round service, start to finish

Formwork solutions from Doka will be deployed on an area of some 19,900 m² right through to the end of this build. The formwork experts’ involvement in the AWO-Föhrenpark project is an all-round solution. From formwork and cycle planning, through delivery and return of allthe equipment, the myDoka online portal (secure 24/7 access to site- and project-specific data), to professional cleaning and reconditioning of the rental material.