Wrekin introduces Armadillo Manhole and Gully Protector Shells

LEADING designer, manufacturer and supplier of specialist products for the civil engineering industry Wrekin Products has created Armadillo – an innovative range of products that benefit contractors, housebuilders and the general public alike.

It’s common practice for manhole covers and gully grates to be installed in the early stages of construction projects, well before the final tarmac is laid. This either means that the products are installed proud of the binding layer and are, therefore, susceptible to being damaged by construction traffic, or if installed level with the binding layer, must be entirely dug out and effectively installed again if damaged. Both of these scenarios would mean additional time worked, costs incurred and potential complications.

Additionally, manhole covers are also specified for the final traffic environment, which means group four D400 covers are commonly installed. However, during the construction phase they are exposed to extreme loads from group five vehicles, including heavy plant and tracked vehicles, which the covers aren’t designed to accommodate. Again, this can result in premature failure and additional costs in materials and labour to put them right before handover.

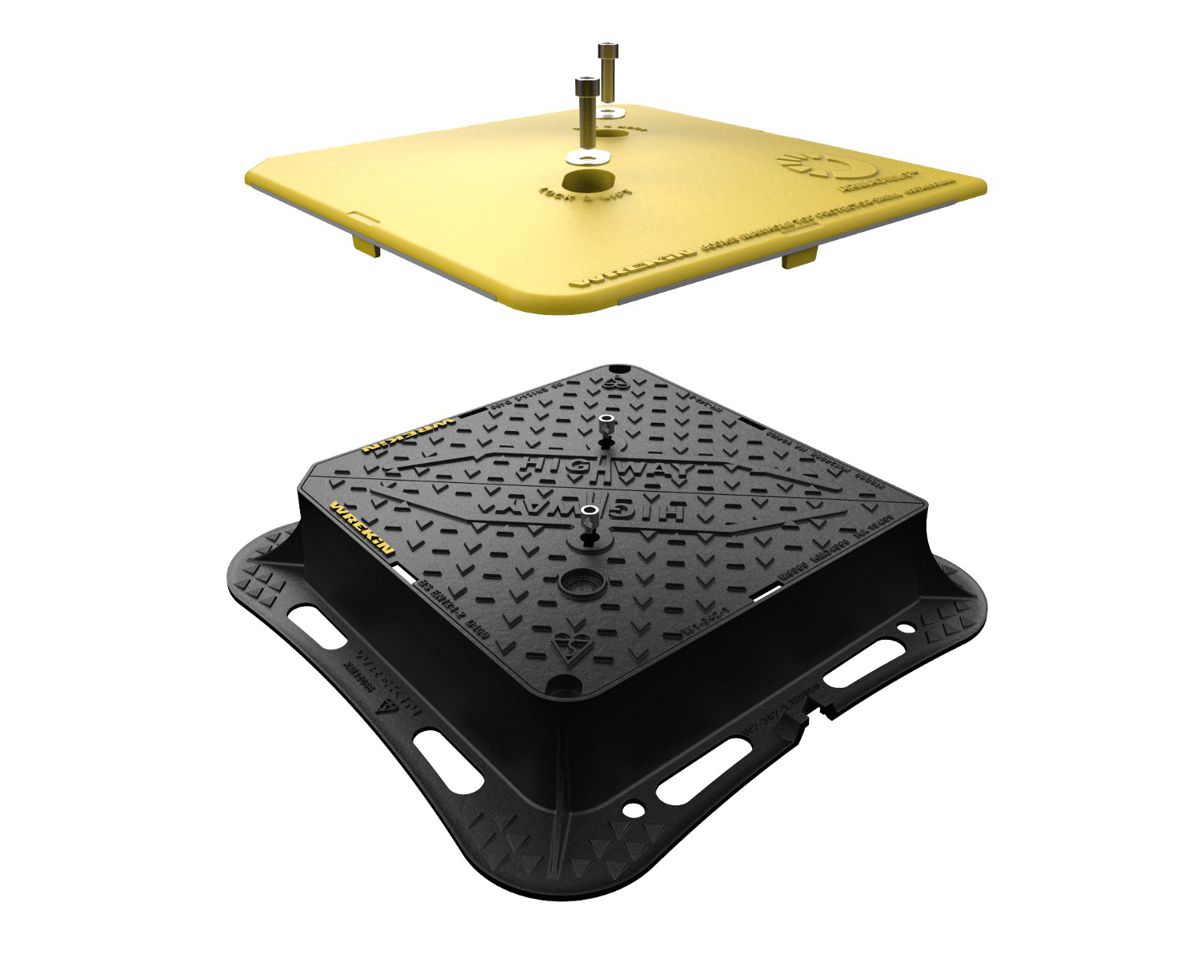

The Armadillo range of protector shells are designed to be placed over manhole covers and gully grates, providing temporary protection from group five traffic during the construction phase of a project. This ensures manhole covers and gully grates start their service life in ‘as new’ condition to optimise longevity.

- Armadillo manhole cover protector shell is compatible with both Wrekin Highway and Tristar manhole covers

- Armadillo gully grate protector shell is compatible with Wrekin Tristar gullies

The Armadillo manhole cover protector shell is also compatible with Wrekin’s patented ClickLift™, which raises Wrekin Highway and TriStar frames to suit the final surface layer without the need for digging out and re-installing.

The cover and the frame are installed at the binding layer level, thereby reducing the possibility of site damage and then, when the final surface layer is being applied, the manhole cover can be raised with the ClickLift™ frame extender simply and quickly. Together, these products perfectly package up to create a solution that saves house builders and groundworkers time and money – allowing them to completely focus on the task at hand.

Gosia Kwapisz, Product Manager at Wrekin Products, said: “We know that for developers and groundworkers time and money is at a premium, which is why we’re constantly pushing ourselves to create new and innovative solutions to the everyday problems that can present themselves during a construction project.

“The premature need for replacement or reinstallation of manhole covers and gully grates is an issue we’ve recognised as having a massive impact on the industry due to the disruption and additional costs it causes. A contributing factor to this, and something that’s often overlooked when specifying products for developments, is the damage heavy plant and site vehicles can cause and how it impacts a product’s longevity before it’s started its actual service life.

“The new product has also been specifically designed to present only smooth faces to traffic – making it less likely to cause damage to site or residents’ vehicles.”

Gosia added: “The Armadillo range also provides assurance and confidence to contractors that there won’t be a need to replace damaged manhole covers or gully grates at the end of construction, enabling them to remove contingencies for replacement items and saving on the overall tender cost – making prices more competitive.

This range delivers a new approach to managing manhole covers and gully grates during construction which not only provides benefits to those who interact with the product but also unlocks the key to longevity of service too. The unique designs are reusable, so contractors can move them on to other phases or future projects. We’re proud to have created Armadillo and look forward to seeing it utilised on sites across the country.”