Almonty gears up for Tungsten Success as Sangdong Mine nears milestone

Almonty Industries Inc., a leading name in the tungsten mining industry, is set to break new ground at its Sangdong Mine in South Korea. The company has successfully completed the pilot plant test works for tungsten concentrate production, paving the way for the installation of processing plant equipment by Metso.

This milestone marks the final stage in the development of flotation processing technology tailored specifically to Sangdong’s unique tungsten ore.

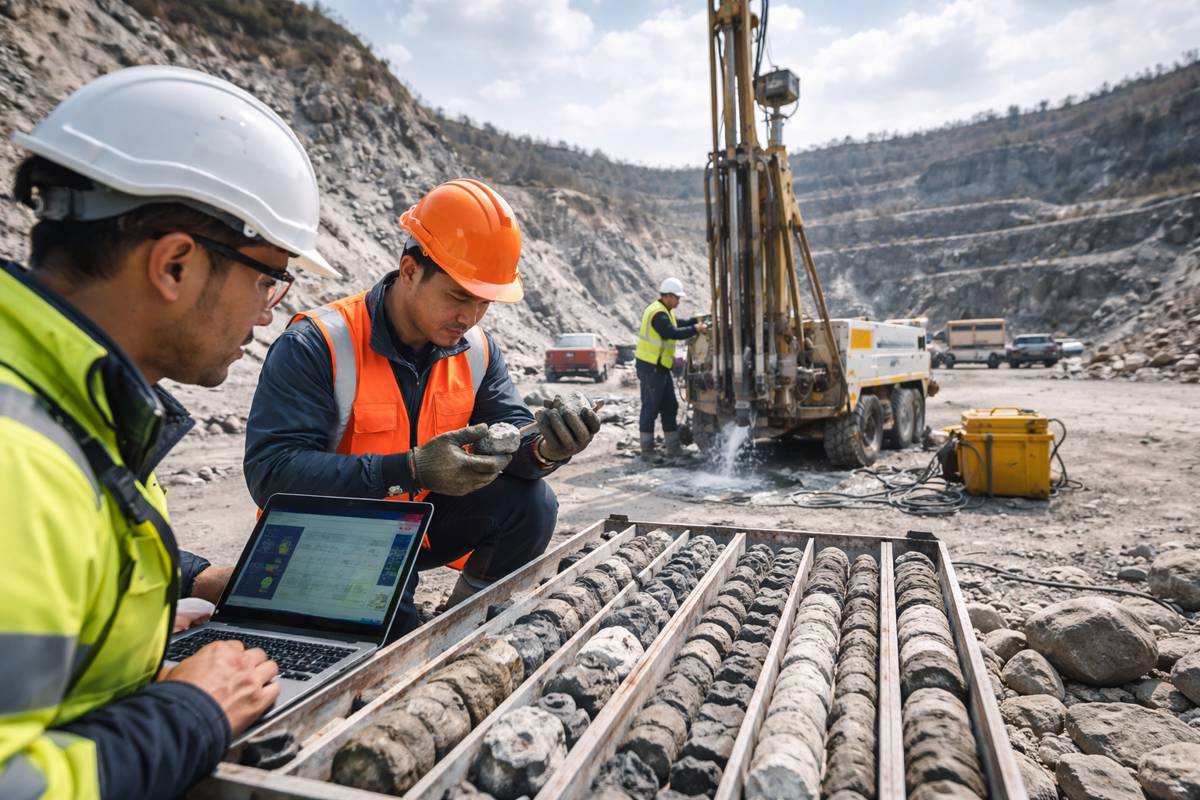

The Pilot Plant Trials

To ensure the smooth operation of its forthcoming processing plant, Almonty conducted extensive pilot plant trials at two separate locations: South Korea and Portugal. These pilot plants, each scaled to 1/500th the size of the actual plant, played a vital role in testing the proprietary flotation techniques developed at the Korea Institute of Geoscience and Mineral Resources. Through meticulous lab-scale and continuous process tests, Almonty refined its approach, gaining operational expertise and uncovering potential challenges before scaling up.

The trials kicked off at the National Laboratory for Energy and Geology in Portugal in September 2023 and continued at the Sangdong Mine during July and August 2024. The primary aim was to validate the stability of the company’s cutting-edge flotation processing technology. These tests proved invaluable, confirming not only the efficacy of the process but also the ability to produce high-quality tungsten concentrate with over 60% WO₃ content—a significant achievement for the mining giant.

Success Across Two Continents

In Portugal, the pilot plant closely mirrored the setup of the future Sangdong industrial plant. With a feed grade around 0.45% WO₃, the Portuguese trial consistently produced concentrates exceeding 60% WO₃, achieving an impressive recovery rate of approximately 82%. The setup validated that the flotation process, designed to maximise efficiency and reduce impurities, could be scaled up effectively.

Meanwhile, at the Sangdong pilot plant, Almonty faced equipment limitations and lower-grade ore challenges. Despite these obstacles, the plant achieved a recovery rate of 86.3%, surpassing expectations. By fine-tuning flotation techniques and optimising reagent adjustments, the company managed to boost tungsten purity during the sulfide flotation stage, which removes impurities. This promising result indicates that Sangdong’s main plant could produce tungsten concentrate with consistently stable WO₃ grades of 60-65%, positioning Almonty favourably against global competitors.

Metso’s Green Light and What It Means for Future Production

The successful trials have given Almonty and its equipment supplier, Metso Outotec, the confidence to proceed with the processing plant installation, having met all necessary design performance parameters. These trials not only validated the technology but also highlighted areas where reagent usage could be reduced without compromising efficiency—a critical insight as the company moves forward.

Lewis Black, Chairman, President, and CEO of Almonty Industries, shared his optimism: “With the successful completion of the pilot plant phase, all preliminary preparations related to process technology development and equipment performance validation have been finalised. With minor adjustments to the equipment and reagents at the processing plant currently under construction, we anticipate stable production of tungsten concentrate from our Sangdong Mine during 2025. The time we have spent building and operating two pilot plants in Korea and Portugal has been essential to ensure the main plant works out the gate. We have been operating the two pilot plants for almost three years, so we have been able to refine and perfect the processing which will ensure a quick and smooth processing commissioning. We are a go.”

Almonty’s Global Footprint and Strategic Vision

Almonty Industries Inc., headquartered in Toronto, Canada, is a major player in the tungsten mining sector, with operations spanning several strategic locations worldwide. Besides the Sangdong Mine, the company owns and operates the Los Santos Mine in Spain and the historic Panasqueira Mine in Portugal.

Additionally, Almonty holds a 100% interest in the Valtreixal tin-tungsten project in northwestern Spain.

- Los Santos Mine: Located about 50 kilometres from Salamanca in western Spain, this site has been under Almonty’s wing since 2011. It produces tungsten concentrate and has been a steady contributor to the company’s output.

- Panasqueira Mine: Acquired in 2016, this Portuguese mine has been producing tungsten since 1896, making it one of the oldest active tungsten mines in the world. Located 260 kilometres northeast of Lisbon, it remains a cornerstone of Almonty’s operations.

- Valtreixal Project: Almonty’s venture into tin-tungsten mining in northwestern Spain adds another layer of diversity to the company’s mineral portfolio, reinforcing its position as a key global supplier.

A Strong Position in the Global Tungsten Market

As the Sangdong Mine moves closer to operational status, Almonty’s strategic investments and innovative approach to tungsten production are set to pay off. The global tungsten market remains heavily reliant on China, which controls the lion’s share of supply. Sangdong’s re-emergence as one of the largest and high-grade tungsten deposits outside of China offers a significant opportunity for diversification and market stability.

The company’s meticulous approach to validating its processes through pilot plant trials has laid a strong foundation for future production. With Sangdong set to come online in 2025, Almonty’s foresight and dedication to innovation put it in a prime position to capitalise on rising global demand for tungsten, particularly in sectors like aerospace, automotive, and energy.

Almonty’s Vision for the Future

With all eyes on Sangdong, Almonty Industries continues to set itself apart as a forward-thinking leader in the mining industry. The successful pilot trials underscore the company’s commitment to excellence, resilience, and sustainable growth. As the world looks towards a future of advanced manufacturing and technology, Almonty’s high-grade tungsten concentrate from Sangdong is poised to play a crucial role.