Building a Sustainable Legacy in the Quarrying and Mining Industries

As December draws to a close, so too does our journey through Quarry and Mining Month at Highways.Today. Throughout the month, we’ve explored the transformative technologies, sustainability initiatives, and challenges that define the quarrying and mining industries.

Now, in our final article of the series, we look ahead to the future—one that balances the increasing demand for resources with environmental stewardship and community development.

Quarrying and mining are industries that have always been foundational to global infrastructure, manufacturing, and technological advancements. As we stand on the brink of an era defined by sustainability and innovation, these industries are tasked with not only meeting the world’s resource needs but also doing so responsibly and efficiently. This is the story of how they can build a sustainable legacy.

Achievements and Challenges

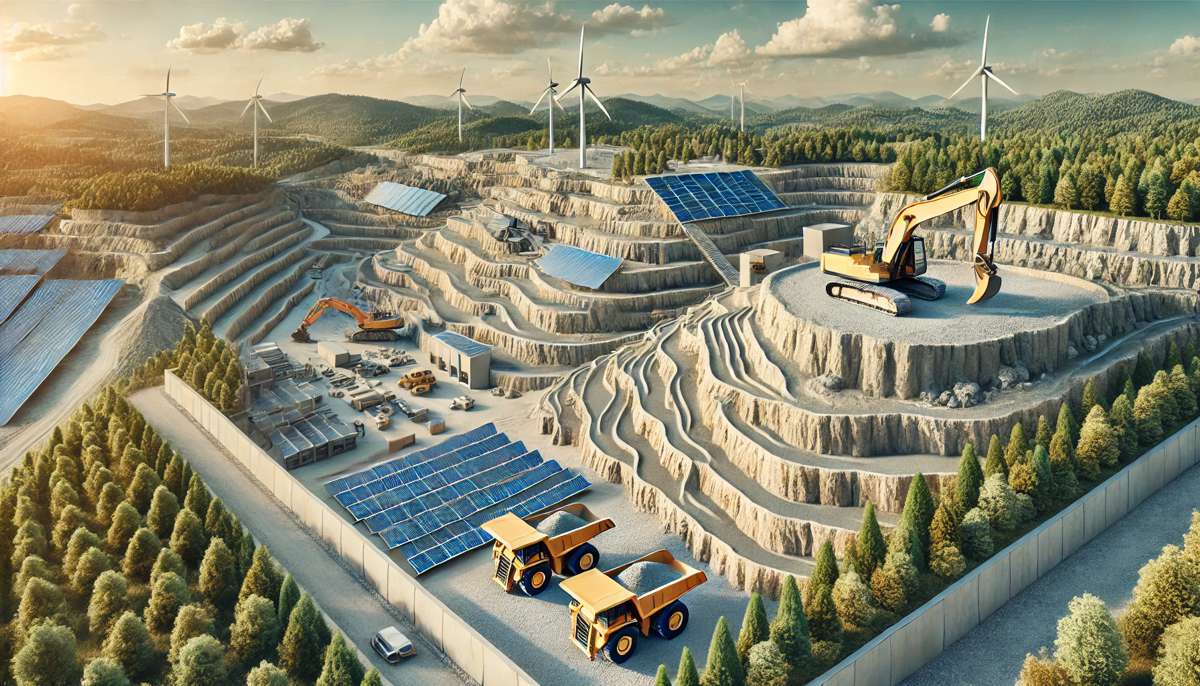

The quarrying and mining sectors have come a long way in integrating sustainability into their operations. From renewable energy adoption to land rehabilitation, there is a growing acknowledgment of the need to reduce environmental impacts.

However, challenges persist, including managing hazardous waste, reducing carbon emissions, and navigating complex geopolitical landscapes.

Highlights of Industry Progress

- Renewable Energy Integration: Mines worldwide are installing solar panels, wind turbines, and hybrid systems to reduce reliance on fossil fuels. For example, a lithium mine in Australia now sources 70% of its energy from solar, demonstrating the feasibility of large-scale renewable adoption. Beyond this, some operations are exploring geothermal energy to power mining equipment, further diversifying clean energy options.

- Water Conservation: Advanced filtration and closed-loop systems have become standard practices in many operations. A copper mine in Chile uses seawater desalination, ensuring fresh water resources remain untouched. Similarly, innovative rainwater harvesting techniques are being implemented in regions prone to drought, creating additional water reserves for dust suppression and processing needs.

- Land Rehabilitation: Decommissioned quarries are being transformed into parks, reservoirs, and wildlife habitats. Canada’s successful reclamation of a quarry into a wetland ecosystem stands as a model for the industry. In other examples, some rehabilitated sites now host renewable energy farms or eco-tourism facilities, demonstrating how former industrial landscapes can be repurposed for community and environmental benefit.

- Technological Innovation: Advances in mining technology are further enhancing sustainability efforts. Autonomous electric vehicles, for instance, are reducing emissions while improving operational efficiency. AI-driven algorithms are optimizing resource extraction, ensuring minimal waste and precise targeting of valuable deposits.

- Community and Collaborative Efforts: Many mining companies are now partnering with local communities and governments to address sustainability goals collectively. Programs focusing on reforestation, environmental monitoring, and shared infrastructure development are setting new benchmarks for socially responsible operations.

Despite these advances, challenges such as waste management, chemical safety, and maintaining biodiversity remain critical focal points. The urgency to address these issues is underscored by global sustainability goals and increasing regulatory scrutiny.

Enhanced collaboration across industries and sectors will be essential to tackle these pressing challenges effectively.

Shaping the Future with Technology

Innovation will be the cornerstone of a sustainable future for quarrying and mining. Technology is already transforming these industries, and its potential to drive efficiency and reduce environmental impacts is immense. By integrating cutting-edge solutions, companies are reshaping traditional approaches and unlocking unprecedented levels of productivity and sustainability.

Autonomous and Digital Tools

Automation and digitalization are revolutionizing how quarries and mines operate. Autonomous haul trucks, drones for site surveying, and robotic drilling systems are not only improving safety but also streamlining complex processes and reducing operational costs. Meanwhile, digital twins—virtual models of physical sites—allow operators to simulate a range of scenarios, from optimizing resource extraction to testing alternative workflows, minimizing waste and energy use.

In addition, machine learning algorithms embedded in autonomous systems enable equipment to adapt to site-specific conditions, further enhancing efficiency.

For example, a mining company in South Africa reduced energy consumption by 15% by using digital twins to streamline equipment operations. Elsewhere, fully autonomous trucks at a copper mine in Peru have increased throughput by 20%, demonstrating the transformative potential of automation.

IoT and Predictive Analytics

The Internet of Things (IoT) is creating a network of interconnected equipment, sensors, and systems, providing real-time data that empowers operators to make informed decisions. IoT-enabled machinery monitors everything from temperature and pressure to fuel efficiency, ensuring that performance remains optimal.

Predictive analytics, powered by AI, takes this a step further by identifying potential issues before they become critical, reducing costly downtime and extending the lifespan of machinery. This technology also enables better resource allocation, ensuring that every operational aspect contributes to sustainability goals.

For example, a quarry in Europe uses IoT sensors to monitor conveyor belt efficiency, reducing energy use and minimizing breakdowns. Similarly, an iron ore mine in Australia implemented predictive analytics, decreasing maintenance costs by 25% and improving equipment availability.

Sustainable Extraction Methods

New and innovative methods are making resource extraction more sustainable than ever before. Biomining, which uses microbes to extract metals from ore, eliminates the need for harsh chemicals, while hydrometallurgical processes improve yield efficiency and reduce environmental risks.

Other advancements include the use of green solvents and low-impact leaching techniques that minimize contamination risks and water usage. These processes are particularly valuable in regions where water is scarce or heavily regulated.

For example, a gold mine in Finland adopted a cyanide-free extraction method, significantly reducing its ecological footprint. In another instance, a rare earth minerals operation in Greenland is piloting hydrometallurgical techniques that aim to achieve 90% recovery rates while maintaining minimal environmental disruption.

As these methods become more widely adopted, the industry is not only meeting growing demand but also setting new benchmarks for responsible resource management.

Materials for the Future

The demand for materials is evolving, driven by technological advancements and the urgent need for sustainable solutions. Aggregates remain the backbone of infrastructure, but minerals like lithium, cobalt, and rare earth elements are playing an increasingly critical role in renewable energy technologies and electric vehicles. Meeting these demands requires a blend of innovative sourcing, robust technological integration, and adherence to ethical practices.

Aggregates – The Backbone of Infrastructure

High-quality aggregates are essential for constructing durable roads, bridges, and buildings that can withstand the test of time and environmental pressures. Quarries are adopting advanced crushers and screeners to optimize production, reduce waste, and improve material quality. Modern processing techniques, such as automated sorting and washing systems, further ensure the consistency of aggregates while lowering energy consumption.

Additionally, quarries are increasingly utilizing recycled construction materials as a sustainable alternative to virgin aggregates. By processing demolition waste, companies are reducing the demand for fresh extractions and minimizing the environmental impact of construction projects.

Critical Minerals – Powering the Green Transition

Lithium, cobalt, and rare earth elements are indispensable for batteries, wind turbines, and solar panels—key components of the global shift to renewable energy. These minerals also underpin advancements in technologies such as electric vehicles, energy storage systems, and advanced electronics. However, the extraction and supply of these critical minerals present significant challenges.

Geopolitical tensions often complicate access to key mineral reserves, while labour practices and environmental degradation in mining regions raise ethical concerns. To address these issues, companies are implementing more transparent supply chains and investing in technologies that enhance sustainable extraction.

For example, advanced leaching techniques and closed-loop recycling systems are being used to extract lithium and cobalt more efficiently while reducing environmental harm. Rare earth mining operations are also exploring methods to minimize chemical usage and manage radioactive by-products responsibly.

For example, companies like Tesla and Apple are leading the charge in supply chain transparency, ensuring that minerals are ethically sourced and environmentally sustainable. Tesla has partnered with mining firms committed to ethical labour practices, while Apple has pioneered the use of recycled rare earth elements in its devices, reducing reliance on virgin resources.

To meet future demand, the industry is also looking to unconventional sources such as deep-sea mining and urban mining—recovering minerals from discarded electronics—to supplement traditional extraction methods. While these approaches come with their own set of challenges, they highlight the innovative thinking required to secure a sustainable supply of critical minerals.

Balancing Progress with Responsibility

As these industries advance, they must balance progress with their social and environmental responsibilities. Environmental, Social, and Governance (ESG) criteria are becoming a standard measure of success, influencing investor decisions and public perception, and driving meaningful change across the sector.

Environmental Stewardship

- Carbon Neutrality: Companies are setting ambitious goals to achieve net-zero emissions by adopting renewable energy and carbon capture technologies. Solar and wind energy installations at mines are becoming common, while innovative projects are exploring the use of geothermal energy to power equipment. Additionally, carbon capture and storage (CCS) technology is being integrated into mineral processing plants to reduce atmospheric emissions.

- Waste Reduction: Recycling tailings and implementing circular economy principles are reducing the environmental impact of waste. Companies are now finding ways to repurpose tailings into construction materials, road bases, or even backfill for mining voids. Some operations are piloting technologies that extract residual metals from tailings, maximizing resource utilization and minimizing waste.

- Biodiversity Protection: Collaborations with ecologists are ensuring that mined areas are rehabilitated to support native species. Programs often include reforestation, wetland restoration, and the introduction of wildlife corridors to reconnect fragmented habitats. In some cases, mining companies are partnering with local conservation groups to create protected areas that benefit both biodiversity and surrounding communities.

Community Engagement

- Education and Employment: Mining companies are investing in local communities through training programs and job creation. Vocational training initiatives are equipping residents with skills for sustainable employment, not just within the mining sector but also in related industries such as construction and renewable energy.

- Health and Safety: Initiatives to improve worker safety and community health are fostering trust and goodwill. Companies are providing modern safety equipment, implementing rigorous training programs, and offering healthcare services to both employees and local residents. Partnerships with NGOs often extend these efforts, ensuring long-term health benefits for the entire community.

- Infrastructure Development: Many mining operations are contributing to local development by building schools, healthcare facilities, and transport infrastructure. These investments not only improve quality of life but also strengthen the social fabric of mining regions, ensuring mutual benefits for companies and communities.

For example, a cobalt mining operation in the Democratic Republic of Congo has reinvested in local schools and healthcare facilities, demonstrating the impact of responsible corporate practices. Beyond this, the company has funded initiatives to improve access to clean drinking water, helping to address a critical need in the region.

Goals for 2025 and Beyond

Looking ahead, the quarrying and mining industries must set clear goals to navigate a rapidly changing landscape.

These goals include:

- Net-Zero Emissions: Expanding renewable energy use and developing carbon capture technologies to achieve carbon neutrality. This involves not only integrating solar, wind, and geothermal energy into operations but also deploying hybrid systems to reduce dependence on fossil fuels. Carbon capture and storage (CCS) technologies can be scaled up to mitigate emissions from mineral processing plants, enabling significant progress toward climate goals.

- Global Collaboration: Partnering with governments, NGOs, academic institutions, and other industries to share knowledge, research, and resources for sustainable practices. Collaborative efforts could focus on addressing global supply chain challenges, implementing international standards for sustainable mining, and facilitating technology transfers to regions with emerging mining sectors.

- Technological Integration: Accelerating the adoption of AI, IoT, and automation to improve efficiency and reduce environmental impacts. Integrating advanced predictive analytics and machine learning into mining operations allows for more precise resource allocation, minimizing waste and energy usage. Autonomous systems, such as self-driving haul trucks and robotic drills, can enhance operational safety and efficiency, particularly in challenging environments.

- Ethical Sourcing: Strengthening supply chain transparency to ensure that materials are extracted responsibly. This includes implementing blockchain technology to trace the origin of critical minerals and verify compliance with ethical labour practices. Companies must also establish partnerships with third-party organizations to audit and certify mining operations, ensuring adherence to environmental and social standards.

- Community-Centric Approaches: Deepening engagement with local communities to create long-term social and economic benefits. Initiatives could include providing educational programs and vocational training tailored to the needs of the local workforce, building essential infrastructure such as schools and healthcare facilities, and supporting community-driven environmental projects. Regular dialogues with community leaders can also foster trust and cooperation, ensuring that mining activities align with local priorities and values.

Building a Sustainable Legacy

Quarrying and mining are more than industries—they are foundational pillars of progress and innovation, shaping the infrastructure and technologies that drive modern civilization. These sectors not only fulfil global demands for essential materials but also provide the backbone for economic growth, technological advancements, and community development. To maintain this momentum, the path forward demands a steadfast commitment to sustainability, collaboration, and technological advancement.

The challenges ahead—ranging from mitigating environmental degradation to addressing social equity and ethical sourcing—offer opportunities for transformative change. By integrating renewable energy solutions, advancing digital technologies, and fostering partnerships with communities and stakeholders, these industries can redefine their role in the global economy. Each innovation, whether in reducing carbon footprints or restoring biodiversity, contributes to a broader vision of responsible resource management.

By addressing environmental challenges with actionable solutions and cultivating positive relationships with the communities they impact, quarrying and mining industries are positioned to leave a lasting legacy—one that future generations will recognize as pivotal to both progress and preservation.

As we close Quarry and Mining Month, I want to express my deepest gratitude for your engagement and curiosity throughout this journey. Your support and enthusiasm underscore the importance of these discussions and inspire us to continue delving into the innovations and stories shaping these dynamic industries. Let’s continue to explore, innovate, and inspire as we work together toward a more sustainable and equitable future.