Breakthrough 3D Imaging Technique Could Transform Nuclear Reactor Safety

MIT researchers have unveiled a ground-breaking method for directly imaging material degradation in three dimensions, as it happens, within a nuclear reactor-like environment. This pioneering technique promises to enhance safety, extend reactor lifespans, and optimise performance in both energy generation and naval propulsion systems.

By harnessing the power of extremely focused, high-intensity X-rays, the team can replicate the harsh conditions materials face inside a reactor, tracking corrosion, cracking, and other failure mechanisms in real-time. Such a capability could fundamentally change how engineers design and maintain nuclear systems.

From theory to real-time observation

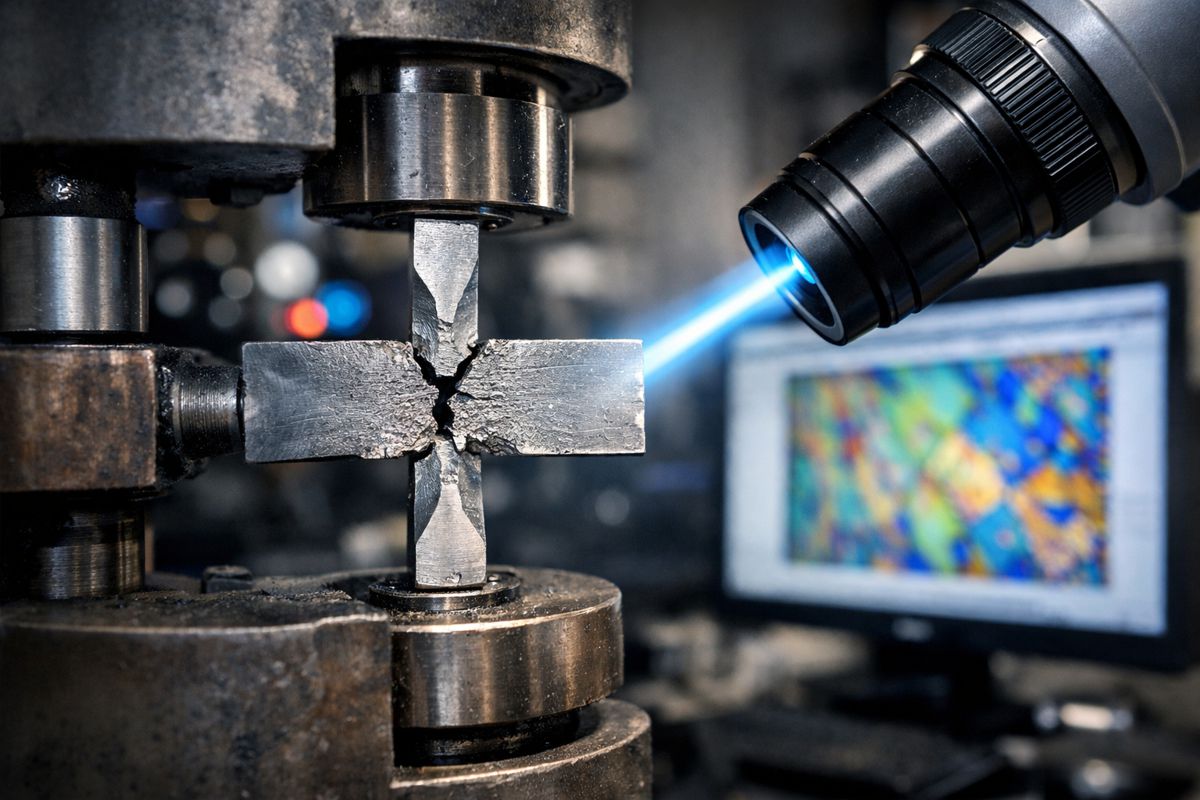

Traditionally, material failures in nuclear settings have been studied retrospectively. Samples would be removed from the reactor environment and analysed under high-resolution instruments — an approach that, while informative, misses the nuanced progression of damage.

Professor Ericmoore Jossou, holding joint appointments in MIT’s Department of Nuclear Science and Engineering (NSE), Department of Electrical Engineering and Computer Science (EECS), and Schwarzman College of Computing, explained the leap forward: “If we can improve materials for a nuclear reactor, it means we can extend the life of that reactor. It also means the materials will take longer to fail, so we can get more use out of a nuclear reactor than we do now. The technique we’ve demonstrated here allows us to push the boundary in understanding how materials fail in real-time.”

The research, published in Scripta Materialia, was led by NSE postdoctoral researcher David Simonne, alongside graduate student Riley Hultquist, Jiangtao Zhao from the European Synchrotron, and Andrea Resta from Synchrotron SOLEIL.

Simonne noted: “Only with this technique can we measure strain with a nanoscale resolution during corrosion processes. Our goal is to bring such novel ideas to the nuclear science community while using synchrotrons both as an X-ray probe and radiation source.”

Engineering the perfect sample

In their experiments, the team focused on nickel — a material widely used in nuclear reactor alloys. Creating a suitable sample, however, proved far from straightforward. Using a process known as solid-state dewetting, they deposited a thin film of nickel onto a substrate, heating it until it formed single crystals.

Unexpectedly, the nickel reacted with the silicon substrate, forming a new compound that undermined the experiment. After extensive trials, a breakthrough emerged: introducing a thin silicon dioxide buffer layer between the nickel and the substrate. This prevented the unwanted reaction but introduced a new challenge — high strain within the crystal structure.

Phase retrieval algorithms, essential for reconstructing a crystal’s 3D size and shape, typically fail under excessive strain. Yet, the researchers discovered that keeping the X-ray beam on the sample for longer gradually relaxed the strain, stabilising the crystal enough for accurate 3D imaging.

Jossou reflected on the novelty of this achievement: “No one had been able to do that before. Now that we can make this crystal, we can image electrochemical processes like corrosion in real-time, watching the crystal fail in 3D under conditions very similar to inside a nuclear reactor. This has far-reaching impacts.”

A dual-purpose discovery

While fine-tuning the method, the researchers stumbled upon an additional application. They found they could manipulate the strain in the material using the X-ray beam itself — a capability that could revolutionise microelectronics manufacturing.

In microelectronics, controlled strain is often introduced to enhance electrical or optical properties. The MIT team’s approach could allow for precision tuning of strain during production, offering engineers a new level of control.

“With our technique, engineers can use X-rays to tune the strain in microelectronics while they are manufacturing them. While this was not our goal with these experiments, it is like getting two results for the price of one,” Jossou remarked.

Beyond nickel

Looking ahead, the team aims to apply this technique to more complex and industrially relevant materials, such as steels and advanced alloys used in nuclear reactors and aerospace engineering. They also plan to investigate how varying the thickness of the silicon dioxide buffer influences strain control.

Commenting on the broader implications, Edwin Fohtung, associate professor at Rensselaer Polytechnic Institute, who was not involved in the study, said: “This discovery is significant for two reasons. First, it provides fundamental insight into how nanoscale materials respond to radiation — a question of growing importance for energy technologies, microelectronics, and quantum materials. Second, it highlights the critical role of the substrate in strain relaxation, showing that the supporting surface can determine whether particles retain or release strain when exposed to focused X-ray beams.”

Paving the way for safer, longer-lasting reactors

By enabling scientists to observe material degradation as it unfolds, this innovation could herald a new generation of nuclear reactor designs — safer, more efficient, and with significantly longer operational lifespans. The ability to adapt the same technique for microelectronics further broadens its potential impact, making it a rare case of scientific progress that bridges multiple high-tech industries.