ORNL Slicer 2 Advances the Future of Large-Scale 3D Printing

In construction and industrial manufacturing, speed is only ever half the story. The real battleground is repeatability: making the same part, to the same quality, again and again, without burning time, money, or material in the process. That’s why the latest release of ORNL Slicer 2, developed by the U.S. Department of Energy’s Oak Ridge National Laboratory (ORNL), matters well beyond the additive manufacturing lab.

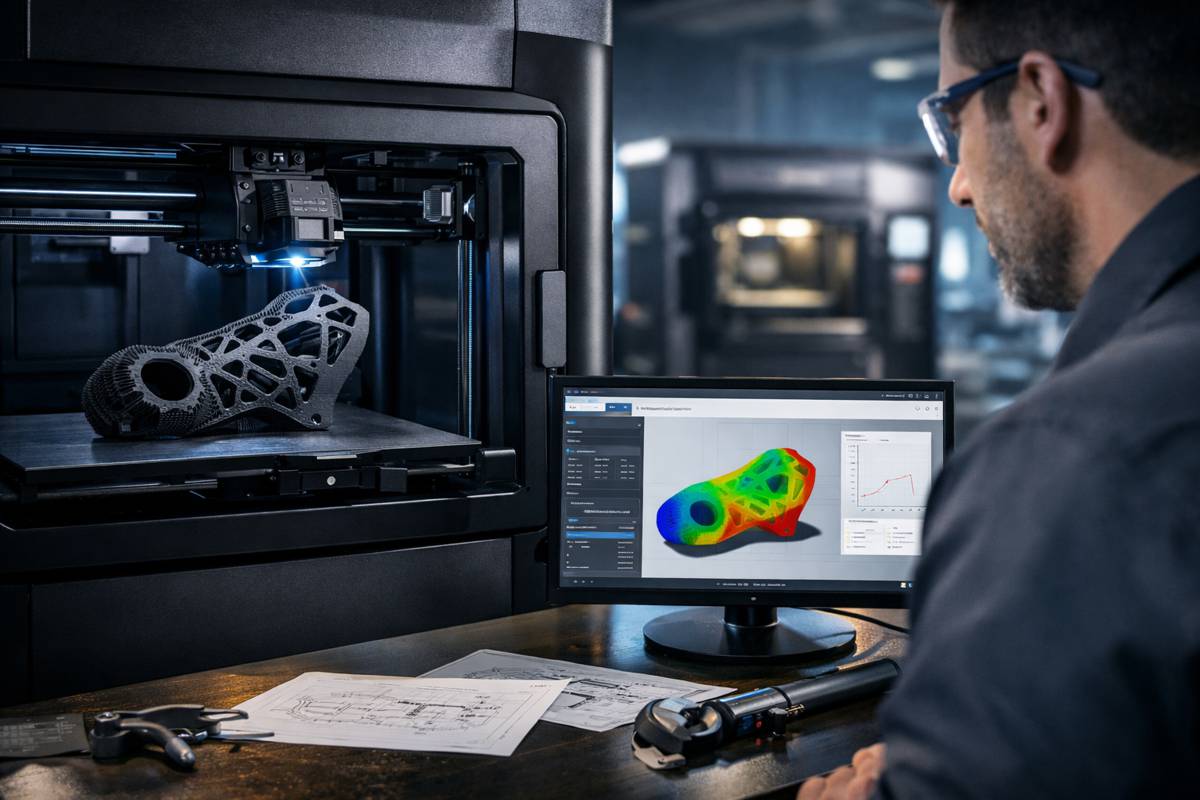

At its core, slicing software turns a CAD model into instructions a 3D printer can understand. That sounds straightforward until the part gets large, the material behaviour changes under heat, the geometry becomes complex, and production demands shift from “interesting prototype” to “reliable component”. ORNL’s updated Slicer 2 is aimed squarely at that moment when additive manufacturing has to stop being clever and start being dependable.

Unlike conventional slicers that mainly break designs into neat, predictable layers, Slicer 2 supports advanced additive workflows for large parts, including the key industrial processes of directed energy deposition (DED) and material extrusion. It’s built to help users keep pace with real-world factory complexity by integrating multiple printer configurations and sensors, enabling smarter process control, and simplifying how manufacturing files are created and shared with users.

In short, it’s an upgrade designed for the jobs where mistakes are expensive and downtime isn’t tolerated.

Why Slicing Software Has Become a Bottleneck

Additive manufacturing has matured quickly, but scaling it is where the hard truths show up. Large-format printing introduces the kinds of issues that don’t always appear in smaller builds: thermal distortion, warping, uneven bead formation, and quality variations from one segment of a build to another. And, naturally, once parts get bigger, a failed print becomes a costly lesson rather than an acceptable experiment.

Traditional slicing tools have generally focused on generating paths and speeds based on geometry alone. For basic jobs, that’s fine. But industrial additive manufacturing isn’t only geometry, it’s geometry plus physics plus machine behaviour, all happening simultaneously in a production environment that still expects schedule certainty.

That’s the gap ORNL is tackling with Slicer 2: moving slicing from “pre-print planning” into something closer to a connected manufacturing workflow, where sensor feedback and machine calibration can inform how the part is built in real time. It shifts the slicer’s role from translator to coordinator, the sort of behind-the-scenes upgrade that rarely makes headlines but quietly changes what’s achievable on the workshop floor.

For construction and infrastructure suppliers exploring additive manufacturing for tooling, bespoke components, or rapid spares, that distinction matters. The industry doesn’t need more novelty. It needs fewer print failures, more predictable tolerances, and reliable output at scale.

What ORNL Slicer 2 Actually Does Differently

ORNL describes Slicer 2 as software that accelerates and simplifies the creation of large 3D printed parts, but the more interesting detail is how it gets there. Conventional slicers convert CAD models into 2D layers and then calculate toolpaths and speeds. Slicer 2 builds on that foundation by supporting multiple types of 3D printers and sensors, while enabling real-time process optimisation with advanced manufacturing systems.

That sensor-driven angle is crucial. In industrial-scale printing, a machine rarely behaves like the neat digital twin engineers wish it was. Material feed rates vary, temperatures fluctuate, bead geometry changes as the print evolves, and calibration drift can create cumulative errors. Slicer 2 is designed to participate in a system where real-time controls respond to what’s actually happening rather than what the model assumed would happen.

ORNL also highlighted improvements that might sound “software-y” on the surface but carry real operational weight. A major change in the latest release is a system designed to automate the creation of files that can be distributed to users more easily. That matters in real facilities where multiple teams, locations, and machines need the same build logic without endless manual configuration and conversion.

As ORNL researcher Alex Roschli explained: “The latest release of Slicer 2 includes many significant updates, improvements, and bug fixes. One major change is a new system that helps automate the creation of files that can be easily distributed to our users.”

It’s not glamorous, but it’s the sort of change that makes additive manufacturing feel less like an isolated capability and more like a scalable production tool.

Better Toolpath Visualisation Means Better Decisions

If slicing is the brain of 3D printing, visualisation is the part that stops people making avoidable mistakes. In many industrial environments, prints are still validated by experienced operators who know where failures tend to occur: corners that cool too quickly, edges that lift, transitions that leave weak seams, or infill strategies that don’t behave the way the simulation promised.

ORNL says the latest updates include improved visualisations for more accurate rendering of cross-sections for toolpathing. That may sound like a minor UI improvement, but in practice, it changes how confidently engineers can interrogate a build before committing machine hours.

This is especially important for large-format prints where the “first time right” principle becomes non-negotiable. In infrastructure manufacturing, where lead times can make or break project schedules, a wasted print isn’t just a cost hit. It’s a supply chain disruption, and those have knock-on effects that travel fast.

By helping users understand how a tool cuts through material at different depths, the software supports greater precision in achieving desired shapes. That’s a practical upgrade with real implications for the industries that rely on robust tooling and accurate geometries, including off-site manufacturing and advanced fabrication for large projects.

Simulating Bead Width Before Printing

One of the most commercially significant upgrades in Slicer 2 is its ability to simulate the effects of multiple bead widths before printing begins. In large-scale additive manufacturing, bead width is a defining factor in build speed, surface quality, and structural behaviour. It’s often determined by nozzle diameter, but not always locked in stone.

Slicer 2 can adjust width during printing to create more complex forms. That’s a meaningful step because it adds flexibility without forcing the manufacturer into hardware changes or overly conservative settings. In real terms, it can help balance competing priorities such as build time, fine detail, and mechanical performance.

More importantly, ORNL notes that based on the dynamic width created by Slicer 2, a machine can implement real-time controls using calibration values and sensor readings. That’s where software starts behaving like an operational advantage, not just a design tool.

In industrial settings, process control is everything. When the print system can adapt to sensor feedback, it can correct course mid-build rather than discovering defects after the fact. That’s the difference between additive manufacturing being “promising” and being truly scalable for consistent production.

Construction, Infrastructure, and Heavy Industry

At first glance, additive manufacturing tends to be associated with aerospace, medical applications, or high-tech automotive labs. Yet the construction ecosystem is increasingly drawn to large-format 3D printing for reasons that are entirely practical: producing tooling, jigs, fixtures, moulds, prototypes, and sometimes end-use parts without waiting for traditional supply chains to catch up.

ORNL Slicer 2 is already being used by aerospace, automotive, and defence organisations, particularly for tooling, delivering reliable end-use components, and prototyping next-generation designs. That matters for infrastructure suppliers because those sectors are typically early adopters of manufacturing innovations that later become mainstream across heavy industry.

There’s a familiar pattern here. Aerospace and defence prove a technology can deliver performance and repeatability under pressure. Automotive scales it. Construction and industrial manufacturing adopt it once the commercial value becomes undeniable, particularly when it helps reduce lead times, improve productivity, and control cost volatility.

In a market where infrastructure projects are under pressure to deliver more with less, additive manufacturing is increasingly seen as a way to reduce waste and improve responsiveness. But the industry won’t commit fully until repeatability and quality control are nailed down. Software like Slicer 2 is part of that maturation, enabling large prints to move beyond the “it worked once” phase into real production confidence.

Staying Competitive Means Producing Faster

ORNL frames the update as a way to help manufacturers stay competitive by reducing costs, improving part quality, and enabling faster production cycles for complex components. Those aren’t abstract benefits. They’re exactly the pressures faced by contractors, equipment manufacturers, and industrial fabricators working under tighter margins and greater uncertainty.

Manufacturers aren’t simply competing on output anymore. They’re competing on their ability to respond to short-notice demand, customisation requirements, and new sustainability expectations, all while maintaining consistency. Additive manufacturing can play a role, but it only works commercially if the process becomes more predictable and less labour-intensive to set up.

That’s why the file automation improvements and the focus on real-time optimisation carry weight. When a facility can generate usable build files faster, distribute them cleanly, and control the print process dynamically, additive manufacturing becomes less dependent on a handful of specialists and more available to standard production teams.

And in practical operational terms, fewer failed prints and fewer quality issues mean less scrap, less rework, and more predictable delivery windows. For infrastructure-related manufacturing, where project timelines can be unforgiving, this is exactly where advanced software can quietly become a competitive differentiator.

ORNL’s Role in Advanced Manufacturing

ORNL is managed by UT-Battelle for the DOE’s Office of Science, which is the largest supporter of basic research in the physical sciences in the United States. That institutional backing matters because the industrial world increasingly relies on national laboratories to bridge the gap between research-grade innovation and deployable capability.

In additive manufacturing, the bottlenecks are often not about “can we print it?” but about whether we can print it reliably, consistently, and economically, with traceability and control. The kinds of improvements described in Slicer 2 point directly at that challenge.

The update is also a reminder that modern manufacturing innovation is rarely just about the machine. It’s about the ecosystem around the machine: sensors, data flows, calibration frameworks, and software that can translate design intent into physical reality without endless trial and error.

Roschli collaborated on the update with Liam White, Cameron Adkins, Ashley Gannon and Michael Borish from ORNL’s Research Application Development group, reflecting the multidisciplinary nature of these tools. Slicer 2 isn’t a single feature upgrade, it’s a continuing effort to turn additive manufacturing into something industry can trust at scale.

From Promising Prototypes to Production-Grade Parts

Large-format additive manufacturing has been “on the brink” for years, not because the machines can’t do impressive work, but because industrial organisations need more than impressive. They need dependable. They need repeatable. They need processes that can handle the awkward realities of production environments, from variable materials and shifting schedules to staff turnover and supply chain disruption.

ORNL Slicer 2 is a practical step forward in that direction. By improving toolpath visualisation, enabling bead-width simulation, supporting real-time controls, and simplifying how usable files are generated and shared, the software targets the real sticking points that slow down industrial adoption.

For the construction and infrastructure supply chain, the opportunity is clear. Additive manufacturing can shorten lead times, support repair and remanufacturing, reduce waste, and enable complex geometries that would otherwise be expensive or slow to produce. But it only becomes viable when the workflow is robust enough to scale without drama.

That’s what this update signals: not a flashy reinvention, but the steady engineering progress that turns advanced manufacturing into everyday capability. And that’s exactly the kind of progress the industry can build on.