Cortec Introduces EcoLine 3860 for Low VOC Metal Protection

Corrosion rarely gets the attention it deserves until something expensive starts failing. A handrail on a bridge, a steel frame inside a coastal treatment plant, the chassis of a road maintenance vehicle, the underside of a loader parked outdoors, or a stockpile of fabricated components waiting for installation, it all adds up. Across construction, infrastructure, manufacturing, and transport, corrosion is a slow-moving threat with fast-moving consequences, driving downtime, premature replacement, and long-term liability.

The scale of the issue is well documented. NACE’s IMPACT study estimates the global cost of corrosion at US$2.5 trillion, roughly 3.4% of global GDP (based on 2013 figures), underlining how widespread and economically damaging metal degradation has become. That’s the context in which corrosion protection coatings live or die: performance first, with sustainability and compliance increasingly becoming part of the procurement checklist rather than a “nice to have”.

Against that backdrop, Cortec® has introduced EcoLine® 3860, a water-based acrylic anticorrosion coating that incorporates renewably sourced resins and carries 27% USDA certified biobased content. On the face of it, it’s a product launch. In practice, it signals something more commercially relevant: biobased content is moving from niche formulations into credible, site-ready corrosion protection where specifiers can consider it without feeling like they’re taking a risk on performance.

A Shift from Solvents to Water-Based Coatings, and Now to Renewable Resin Content

Industrial coatings have been gradually reshaped by two overlapping pressures: regulations around emissions, and end users’ desire for safer, easier-to-handle products. Over the past few decades, water-based coatings have steadily gained ground as an alternative to traditional solvent systems, largely because they can reduce VOC emissions while remaining practical for widespread industrial use.

Cortec positions EcoLine® 3860 as an extension of its VpCI®-386 anticorrosion coating family, which it describes as a “flagship” line that helped support the wider market’s move from solvent-based products to water-based corrosion-inhibiting paints. That evolution matters because it reflects the real-world pattern in construction and industrial maintenance: new chemistry only becomes mainstream when it works at scale, across varied sites, operators, and climates.

EcoLine® 3860 pushes this familiar trend forward one more step by introducing renewably sourced resin content into a water-based acrylic system. It’s a notable milestone because resin technology is often where sustainability aspirations collide with performance expectations. When the coating is the last line of defence against corrosion, no one wants to be the first to trial something that looks great on paper but fails in the field.

What EcoLine 3860 Is Designed to Deliver on Site

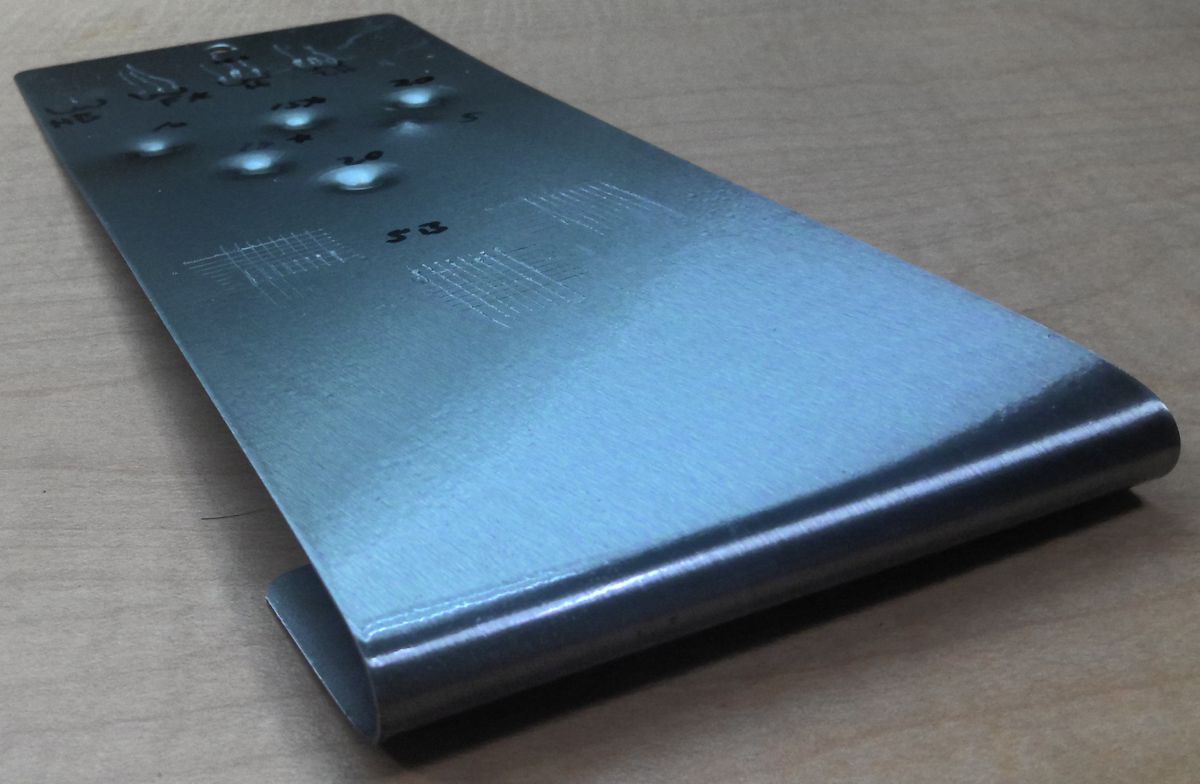

EcoLine® 3860 is described by Cortec as a fast-drying, water-based acrylic topcoat intended for direct-to-metal applications, with multi-metal protection and “superior UV resistance” for outdoor, unsheltered environments. Acrylic chemistry remains a widely used platform in protective coatings because it tends to balance flexibility, adhesion, and weathering resistance, especially in environments where temperature swings, sunlight exposure, and intermittent moisture create predictable wear mechanisms.

From an infrastructure and construction standpoint, the “direct-to-metal” angle is not a throwaway feature. It hints at simpler application workflows, fewer system layers for some use cases, and reduced labour time in maintenance settings. For fabricators, plant operators, and asset owners, that practical value often outweighs big-picture sustainability messaging, not because sustainability isn’t important, but because the day-to-day reality is time, cost, and keeping equipment operational.

Cortec states EcoLine® 3860 can be applied either clear or colour matched to custom colours at a dry film thickness of 1.5–3.0 mils (38–76 µm). That combination of unobtrusive appearance and functional protection is relevant for a wide spread of industrial uses where the coating is expected to protect without interfering with markings, finishes, or assembly visibility.

Low VOC Compliance Is No Longer a Bonus Feature>

VOC limits are increasingly embedded into project requirements, especially in public infrastructure, large industrial sites, and international projects where owners want future-proof procurement. Cortec reports EcoLine® 3860 as registering at 0.6 lbs/gal (72 g/L), positioning it “well within Green Seal and EPA guidelines for low VOC coatings.”

Those numbers land in a useful middle ground. For context, the US EPA’s architectural coatings compliance guide lists VOC content limits that can be significantly higher depending on coating category, with industrial maintenance coatings shown at 450 g/L, for example. Green Seal standards can be tighter depending on category, with GS-11 noting VOC thresholds such as 50 g/L for certain product classifications. In short, 72 g/L is not “zero VOC,” but it sits firmly in the low-VOC conversation while remaining in a performance-oriented industrial space.

That distinction matters. The coatings market has sometimes struggled with messaging that oversimplifies VOC performance into a single label. Specifiers and compliance teams increasingly want exact numbers, clear documentation, and confidence that a coating won’t introduce unpleasant surprises during audits, especially on projects involving multiple contractors and cross-border reporting requirements.

Biobased Content Moves From Concept to Procurement-Ready Detail

The defining headline attribute of EcoLine® 3860 is its 27% USDA certified biobased content. For asset owners and manufacturers who are actively trying to increase renewable content in their materials, that figure gives procurement teams something measurable to work with rather than vague sustainability language.

It’s also a sign of where industrial coatings are heading. In many areas of construction technology, sustainability improvements often arrive as operational efficiency, reduced waste, fewer hazardous materials, or longer service intervals. Biobased resin content fits into that broader narrative, but it has to earn its place through performance. No specifier wants a coating selected on sustainability grounds that shortens maintenance cycles or increases failure risk in harsh environments.

From a supply chain perspective, renewable content isn’t just about optics either. As product declarations, lifecycle reporting, and contractor environmental requirements become more standardised, materials with verifiable renewable components can become easier to justify in bid documentation. It doesn’t mean every project will pay more for it, but it does mean products like this may start appearing more often on approved lists where sustainability now carries commercial weight.

Industrial Corrosion Protection Needs Incremental Wins, Not Reinvention

Corrosion prevention in the real world is a game of cumulative advantage. A slightly better barrier, a more forgiving application window, improved UV performance, lower VOC exposure for workers, easier compliance documentation, or a renewable content metric that helps a client meet internal goals, any one of these can shift buying decisions when multiplied across fleets, facilities, and construction programmes.

EcoLine® 3860 seems positioned as one of those incremental wins. It doesn’t claim to rewrite the corrosion playbook. Instead, it takes an established protective coating format, water-based acrylic, and introduces a notable sustainability step through renewably sourced resins while maintaining a specification-friendly VOC profile and typical protective coating functionality.

That’s arguably the smartest path for industrial coatings innovation. The market is conservative for good reason. Bridges, ports, plant equipment, and industrial structures can’t afford trial-and-error chemistry. What they can accept is a gradual evolution where performance expectations stay consistent while the environmental profile improves, one product generation at a time.

Setting the Stage for More Advanced Biobased Anticorrosion Coatings

Cortec describes EcoLine® 3860 as its first biobased acrylic anticorrosion paint and frames it as a milestone that “sets the stage” for further developments in biobased anticorrosion coatings. That future-facing statement will resonate with industrial users who want to move towards renewable content but need supplier consistency, reliable product support, and a visible innovation pipeline.

In practical terms, the coating’s arrival also reflects a wider industry recalibration. Sustainability isn’t confined to electric machines and alternative fuels anymore. It’s increasingly woven into the materials that protect infrastructure and equipment over decades, not months. Protective coatings sit right in that long-term value chain, because extending the life of metal assets is often one of the most direct ways to cut embodied carbon and reduce lifecycle costs without compromising operational capability.

For construction professionals and policymakers, the announcement is a reminder that the transition to more sustainable infrastructure is built from many small, technical decisions as much as from big headline projects. A corrosion coating may not be glamorous, but it can prevent failures, reduce disruption, and extend the service life of critical assets. Considering what corrosion costs the global economy, every credible step forward matters.