Embodied AI & Robotics Moving From Concept to Reality

The global construction, infrastructure and industrial technology sectors are watching embodied artificial intelligence move out of laboratories and pilot programmes and into commercial reality. Labour shortages, rising safety requirements, increasing site complexity and relentless productivity pressure have created fertile ground for robotics that can operate alongside people rather than behind fences. Now, Faraday Future has decided to formally enter the embodied AI robotics market, a signal that robotics is beginning to intersect with mainstream industrial ecosystems in the United States.

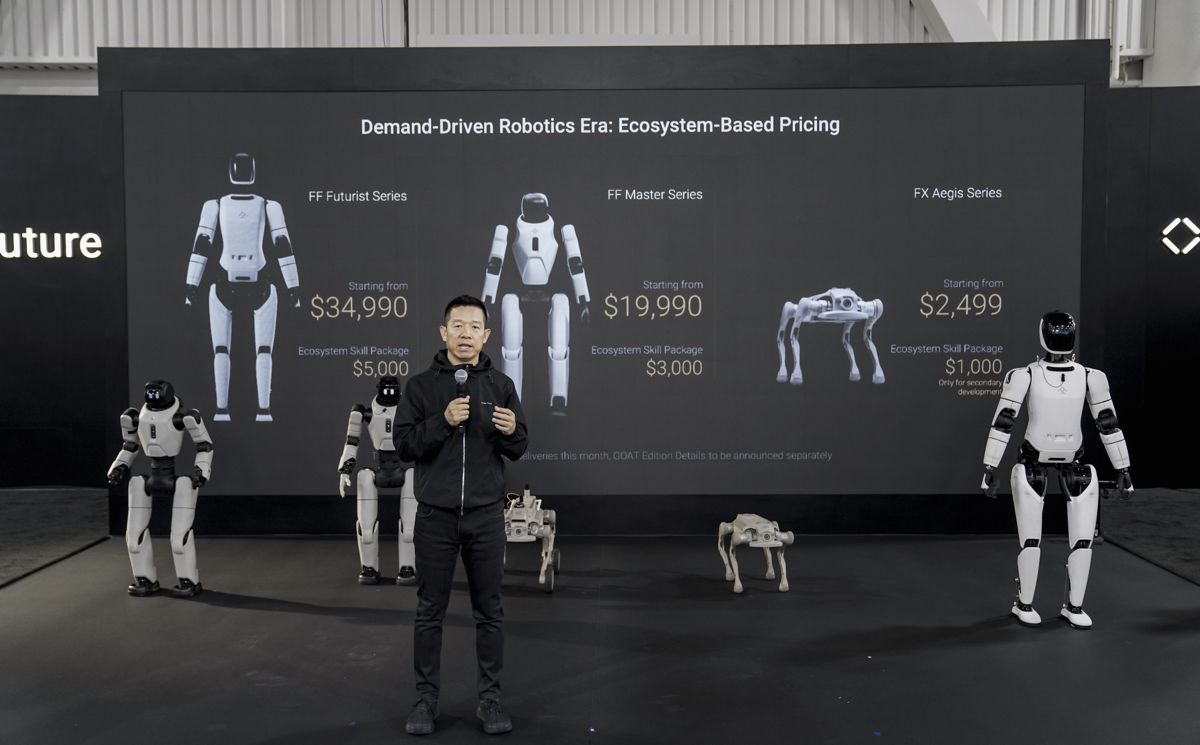

At the annual National Automobile Dealers Association show in Las Vegas, Faraday Future Intelligent Electric unveiled three embodied AI robotic platforms under its newly established FF EAI-Robotics Inc. subsidiary. The move positions the California-based company among a small but growing group of US firms attempting to commercialise humanoid and quadruped robots at scale, while tying robotics into existing vehicle, dealership and service infrastructures. For construction professionals and infrastructure investors, the significance lies not in the spectacle of humanoid robots on a trade-show floor, but in the strategic framing: robotics as an extension of industrial systems rather than a novelty product.

Robotics as an Extension of Industrial Ecosystems

Embodied AI robotics is increasingly viewed as a response to structural challenges facing construction, logistics and public infrastructure. According to the World Economic Forum, automation and robotics are becoming central to addressing workforce gaps and improving safety in physically demanding sectors, particularly where skilled labour shortages are persistent. The United States construction industry alone continues to face a shortfall of hundreds of thousands of workers, while project complexity and regulatory expectations continue to rise.

Faraday Future’s approach leans heavily on this reality. Rather than positioning robots purely as consumer companions, the company frames its robots as productive assets designed to integrate with commercial, public service and industrial workflows. That positioning matters. The path to large-scale adoption in construction and infrastructure has historically favoured machines that slot into existing processes, supply chains and compliance frameworks, rather than those that require entirely new operational models.

By launching its robotics business alongside its electric vehicle operations, Faraday Future is effectively arguing that vehicles and robots share more than just batteries and processors. Both are mobile intelligent systems, increasingly defined by software, data and connectivity. This convergence is already visible across the industry, from autonomous construction equipment to sensor-laden fleet vehicles feeding data back into digital twins and asset management platforms.

Three Platforms Targeting Distinct Roles

The initial portfolio comprises three embodied AI platforms, each targeting different operational contexts. The FF Futurist is positioned as a full-size professional humanoid robot intended for structured commercial environments such as hotels, showrooms, museums, education facilities and, eventually, industrial settings. The FF Master adopts a smaller, more athletic humanoid form aimed at interaction-heavy roles, while FX Aegis takes the form of a quadruped robot designed for security, inspection and outdoor operations.

What differentiates this launch from many robotics announcements is the stated intention to begin deliveries within weeks rather than years. Faraday Future confirmed that sales and non-binding pre-orders opened immediately, with the first batch of deliveries planned for the end of February. The company reported that more than 1,200 units are already covered by paid B2B deposits, signalling early interest from commercial partners rather than speculative consumer buyers.

While deposit figures alone do not guarantee long-term adoption, they do indicate that embodied AI is starting to be evaluated as a near-term operational tool rather than a distant technology bet. For infrastructure owners and construction firms accustomed to evaluating equipment purchases on return-on-investment timelines, this shift is critical.

Technology Stack Reflects Industrial Ambitions

At the technical level, Faraday Future has anchored its humanoid platforms on established AI and compute architectures rather than proprietary experimental stacks. The FF Futurist is powered by NVIDIA’s Orin platform, delivering up to 200 trillion operations per second of computing performance. This choice aligns the robot with the same AI hardware ecosystem increasingly used in autonomous vehicles, smart machinery and industrial automation systems.

Sensor fusion plays a central role. The FF Futurist combines high-resolution cameras, fisheye and RGB-D cameras, 3D LiDAR and tactile sensors to build situational awareness in complex environments. Connectivity via Wi-Fi and 5G supports remote control, collaborative operation and over-the-air updates, capabilities that are becoming standard expectations for connected industrial assets.

From a mechanical perspective, the humanoid platform features 28 high-performance motors delivering peak torque of up to 500 Newton-metres, alongside a hot-swappable battery system enabling extended operation without lengthy downtime. These specifications suggest an emphasis on continuous use scenarios rather than short demonstration cycles, a distinction that matters on construction sites and in industrial facilities where uptime directly impacts productivity.

Quadruped Robotics and Infrastructure Safety

The FX Aegis quadruped robot addresses a different but equally relevant set of infrastructure challenges. Designed for security, inspection and emergency response, Aegis is capable of navigating uneven terrain, climbing slopes of up to 40 degrees and overcoming obstacles exceeding 13 inches. Such capabilities align closely with the requirements of industrial sites, utility corridors and infrastructure assets where human access can be hazardous or inefficient.

Quadruped robots have already demonstrated value in sectors such as oil and gas, mining and power generation, where routine inspection and monitoring tasks expose workers to risk. By enabling autonomous patrol, remote operation and integration with existing security and monitoring systems, platforms like Aegis could play a role in improving safety outcomes while reducing labour intensity.

The modular nature of the platform, supporting additional sensors, communication modules and even robotic arms or fire-suppression equipment, reflects broader industry trends toward adaptable robotic platforms. For infrastructure operators managing diverse asset portfolios, flexibility often determines whether a technology scales beyond pilot projects.

Pricing Signals a Shift Toward Commercial Viability

One of the more consequential aspects of the announcement lies in pricing. Faraday Future disclosed starting prices of $34,990 for the FF Futurist, $19,990 for the FF Master and $2,499 for the FX Aegis, with additional ecosystem skill packages priced separately. While these figures remain significant investments, they are notably lower than the six-figure price tags historically associated with advanced humanoid robotics.

This pricing strategy appears designed to lower barriers to experimentation for commercial users, particularly when combined with proposed financing, leasing and rental options. In construction and infrastructure, where capital expenditure decisions are often balanced against project-specific timelines, flexible commercial models can be as important as technical capability.

The company describes its approach as an ecosystem-based pricing framework, shifting value from one-off hardware sales toward ongoing software, data and service engagement. This mirrors trends seen in construction equipment, where manufacturers increasingly rely on digital services, subscriptions and lifecycle support to drive long-term value.

Human–Machine Collaboration as a Productivity Lever

Faraday Future’s robotics narrative consistently returns to the idea of human–machine collaboration rather than replacement. That framing aligns with research from organisations such as McKinsey and the International Labour Organization, which suggests that the most productive applications of AI and automation augment human capabilities rather than eliminate them entirely.

The company’s founder and Global Co-CEO YT Jia articulated this vision during the launch, stating: “Working alongside humans, we believe EAI robots will help reshape productivity models and drive a new leap forward in productivity through human–machine symbiosis.” The emphasis on collaboration resonates strongly in construction and infrastructure, where safety regulations, union frameworks and practical realities limit the scope for full automation.

Humanoid robots capable of interacting naturally with people, understanding multiple languages and adapting to dynamic environments could support roles ranging from site coordination and logistics to training and public engagement. While such applications remain aspirational in many cases, the underlying drivers are real and persistent.

Automotive Channels as a Robotics Distribution Network

An unusual but potentially influential aspect of Faraday Future’s strategy is its intention to leverage automotive dealership and partner networks as future robotics sales and service channels. Through its FF Par co-creation partner programme, the company envisions dealers evolving into “intelligent terminal operators” capable of selling, servicing and supporting both vehicles and robots.

For the construction and infrastructure ecosystem, this approach could accelerate market penetration by using established commercial networks rather than building robotics-specific distribution channels from scratch. Heavy equipment manufacturers have long relied on dealer networks to provide local support, maintenance and training, and robotics may ultimately follow a similar path.

The overlap between vehicle electrification, connected systems and embodied AI suggests that convergence across these channels is not only plausible but likely. If robotics adoption accelerates, familiar commercial structures could play a decisive role in determining which platforms achieve scale.

Data, Open Platforms and Long-Term Industry Impact

Beyond hardware, Faraday Future emphasises open platforms, decentralised data architectures and protocol-based ecosystems as foundations for long-term growth. Data generated by embodied AI robots operating in real-world environments has significant potential value, particularly for training, optimisation and predictive analytics.

In construction and infrastructure, data-driven insights increasingly underpin asset management, safety planning and operational decision-making. Robots that contribute to these data streams, while operating under regulatory and data-sovereignty constraints, could become integral components of digital infrastructure ecosystems.

The company’s assertion that global robot ownership could eventually reach tens of billions of units may be ambitious, but it reflects a broader industry belief that embodied AI will become ubiquitous across sectors. Whether that scale is achieved remains uncertain, but the direction of travel is increasingly clear.

From Demonstration to Deployment

For construction professionals, investors and policymakers, the relevance of Faraday Future’s robotics launch lies in its attempt to bridge the gap between technological promise and commercial deployment. The combination of near-term delivery timelines, comparatively accessible pricing and integration with existing industrial ecosystems suggests a pragmatic approach rather than speculative futurism.

As embodied AI continues to mature, its impact on construction, infrastructure and public services will depend less on headline announcements and more on sustained performance in demanding environments. The coming months, as early units are deployed and evaluated, will provide clearer insight into whether this latest entrant can translate ambition into operational value.