Physics First Autonomy Reshaping the Economics of Mining Haulage

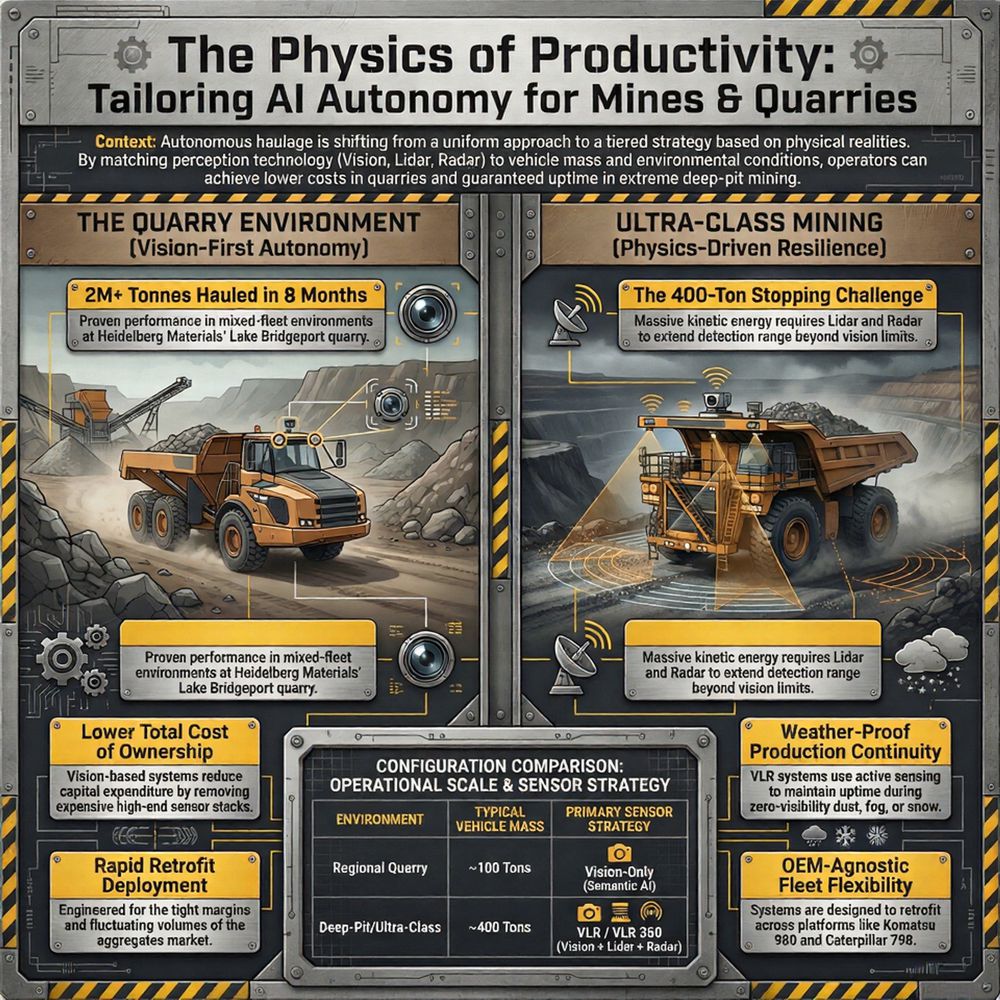

Autonomous haulage has spent more than a decade promising step changes in productivity, safety and cost control for the global mining industry. Yet progress has been uneven. Solutions that work well in controlled, shallow quarry environments have struggled to scale into deep pit, ultra class mining, where physics, weather and sheer operational complexity rewrite the rules.

Pronto.ai has now taken a deliberate step away from the one size fits all autonomy, unveiling a tiered portfolio designed around the realities of heavy haulage rather than ideology.

The introduction of Pronto AHS VLR and Pronto AHS VLR 360 marks a structural shift in how autonomy is packaged and deployed. Rather than forcing operators into a single sensor strategy, Pronto is formalising a spectrum of autonomy editions that align perception technology with vehicle mass, stopping distances, weather exposure and economic constraints. For an industry grappling with rising costs, tightening safety regulations and chronic labour shortages, that alignment matters more than ever.

Proven Quarry Performance Sets the Foundation

Pronto’s expansion into deeper and harsher mining environments is underpinned by real world operating data rather than lab simulations. At Heidelberg Materials’ Lake Bridgeport quarry in Texas, the company’s Vision Only autonomous haulage system has already hauled more than two million tonnes of material in under eight months. Crucially, that performance has been delivered in a mixed fleet environment, where autonomous trucks operate alongside human driven equipment, contractors and mobile plant.

For quarry operators, the significance lies in the economics. Vision based autonomy, when engineered correctly, removes much of the cost and complexity associated with high end sensor stacks. Faster retrofits, lower capital expenditure and reduced maintenance overheads translate directly into lower total cost of ownership. In an aggregates market where margins are often tight and volumes fluctuate with infrastructure spending, those factors determine whether autonomy is viable at all.

Yet quarry success does not automatically translate to hard rock mining. The physics of a 100 tonne rigid truck on short haul cycles are fundamentally different from those of a 400 tonne ultra class hauler descending long ramps in poor visibility. Pronto’s latest announcement recognises that distinction rather than attempting to gloss over it.

Why Physics Dictates Perception

At the heart of Pronto’s strategy is an explicit acknowledgement that autonomy is constrained by physics as much as software. Ultra class haul trucks carry enormous kinetic energy, and their stopping distances expand dramatically with speed, gradient and load. Vision systems alone, no matter how advanced, face hard limits on detection range and reliability when dust clouds, fog or snow dominate the operating environment.

This is not an academic concern. Tier 1 mining operations run continuously, often in climates where visibility can collapse without warning. Downtime caused by weather not only erodes productivity but disrupts tightly optimised production schedules that span drilling, blasting, loading and haulage.

As Pronto CEO Anthony Levandowski explains: “Autonomy is not a one-size-fits-all proposition. The physics of stopping a 100-ton truck in a Texas quarry are radically different from stopping a 400-ton hauler in a Chilean blizzard. We proved that Vision is the killer app for quarries, delivering the lowest total cost of ownership in the industry. Now, with VLR and VLR 360, we are bringing that same ‘AI-First’ intelligence to the world’s most challenging mining operations, fortified with the active sensing required to guarantee uptime in zero-visibility conditions.”

The emphasis on uptime is telling. In large scale mining, the value of autonomy is not simply labour substitution, but predictable, uninterrupted production under conditions that routinely sideline human operators.

From Sensor Wars to Sensor Strategy

For much of the past decade, autonomous haulage has been framed as a contest between sensor modalities. Vision versus Lidar, cameras versus radar, each championed as the definitive path to autonomy. Pronto’s tiered architecture effectively declares that debate obsolete.

The Pronto Editions portfolio allows operators to select an autonomy configuration that matches their operational design domain rather than their vendor’s philosophy. Vision remains central, providing semantic understanding of the environment, but is augmented where physics demands additional range or robustness.

In the VLR configuration, long range Lidar adds precise geometric mapping, while radar ensures detection capability through dust, fog and precipitation. The result is a fail operational system designed to maintain production when optical systems alone would falter. For mines operating in extreme climates or deep pits, this capability directly supports production continuity and safety compliance.

The VLR 360 edition extends this concept further, surrounding the vehicle with a comprehensive sensor envelope. This full perimeter awareness is particularly relevant in congested loading zones, waste dumps and mixed traffic environments where interactions with support vehicles, light trucks and personnel are unavoidable.

As Levandowski puts it: “With the launch of Pronto Editions, we are declaring the end of the ‘sensor wars’. We don’t use Lidar because we can’t do Vision; we use Lidar where it’s the right physics to solve specific customer problems.”

Aligning Autonomy With Mining Economics

Beyond safety and perception, the commercial implications of a tiered autonomy model are significant. Mining operators increasingly expect technology investments to scale with asset value and operational complexity. A retrofit solution that makes sense for a regional quarry does not justify the same spend as a system deployed across a multi billion dollar iron ore operation.

By preserving its Vision Only edition as a low barrier entry point, Pronto addresses the quarry and aggregates market without forcing unnecessary cost. At the same time, the VLR and VLR 360 editions provide a clear pathway for miners operating ultra class fleets to adopt autonomy without compromising uptime or compliance.

This approach also reflects broader industry trends. According to multiple mining technology studies published over the past five years, autonomous haulage delivers the strongest returns when deployment risk is minimised and utilisation remains high. Systems that frequently disengage due to weather or visibility erode confidence and delay wider rollouts. Sensor strategies that prioritise operational resilience, even at higher upfront cost, tend to outperform over the life of the mine.

OEM Agnosticism and Fleet Flexibility

Another differentiator retained across the Pronto Editions portfolio is OEM agnosticism. Rather than tying autonomy to a single truck manufacturer, Pronto’s systems are designed to retrofit across platforms. This flexibility is especially relevant for operators running mixed fleets acquired over decades of mine development.

The VLR editions are already being deployed on some of the largest haul trucks in production, including platforms such as the Komatsu 980 and Caterpillar 798. For miners, the ability to introduce autonomy without wholesale fleet replacement reduces capital exposure and accelerates time to value.

OEM agnosticism also aligns with evolving procurement strategies, where miners seek to avoid vendor lock in and maintain leverage across their supply chains. In an era of volatile commodity prices and geopolitical uncertainty, flexibility has become a strategic asset rather than a nice to have feature.

A Broader Signal for the Autonomous Mining Sector

The launch of Pronto AHS VLR and VLR 360 is about more than product expansion. It signals a maturation of autonomous haulage from experimental deployments to infrastructure grade systems engineered around real world constraints. By grounding autonomy in physics and economics rather than marketing narratives, Pronto is reinforcing a trend toward pragmatic, outcome driven automation.

For policymakers and investors, the implications are equally relevant. Autonomous haulage that improves safety, reduces emissions through smoother driving cycles and sustains productivity under extreme conditions supports broader goals around responsible resource extraction and resilient supply chains. As demand for critical minerals accelerates, the ability to operate mines efficiently and safely becomes a matter of national and economic security.

For the mining industry itself, the message is clear. Autonomy is no longer a binary choice between human drivers and machines. It is an adaptable toolkit, one that must be configured to match the unique physics, risks and economics of each operation.