MATEENBAR Fiberglas Rebar manufacturing comes to the US

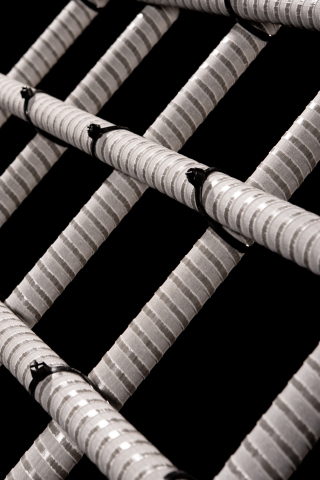

MATEENBAR™ Fiberglas™ Rebar, a lighter, more durable and corrosion-resistant concrete reinforcement alternative to steel rebar for structural, heavy-load applications, launched April 14, 2021, to customers throughout the U.S.

With the U.S. preparing for new investments to rebuild its aging infrastructure and create new, stronger buildings, bridges, seawalls, rail systems and other structures, the need for domestically manufactured, higher-performing and more cost-effective materials has never been more critical.

MATEENBAR™ Fiberglas™ Rebar is manufactured in a new Concord, North Carolina facility using Owens Corning Type 30® single-end roving fiberglass originating from the company’s Amarillo, Texas, Composites facility.

It will be solely distributed by Owens Corning Infrastructure Solutions (OCIS) to enable increased market access to ACI, ASTM and CSA compliant, high-performance fiberglass rebar (also referred to as GFRP, FRP or composite rebar).

“We are proud to provide a world-class fiberglass rebar product to the federal and state departments of transportation as a proven substitute to steel reinforcements in building more durable and longer-lasting concrete structures” said Chad Fenbert, general manager of OCIS.

Mateenbar™ is recognized globally as a best-in-class concrete reinforcement product and has been used in more than 1,500 construction projects worldwide and certified in 2,500 independent, third-party tests. It is a proven, durable, corrosion resistant reinforcement designed to provide concrete structures with longer service life than traditional steel rebar. Additionally, the product is four times lighter than steel, enabling faster installations with reduced labour and physical demands, as well twice the strength of steel ensuring consistent performance.

“Material conversion in infrastructure is central to the long-term growth of OCIS. Mateenbar™ has built an incredibly powerful global product leadership position and we are excited that our Type 30® single end roving fiberglass made in Amarillo, Texas will now be the reinforcement of choice for this product and enable the building of better structures. Our high-quality products provide consistent and reliable performance to our customers who have come to rely on our differentiated solutions,” added Marcio Sandri, president of Owens Corning Composites.

“We are honoured to work with OCIS to introduce a stronger, stiffer and more cost-effective product that extends service life in the U.S. market. OCIS has established itself as the leading global brand for sustainable rebar by enabling customers to switch from steel to fiberglass rebar with ease and confidence,” said Nick Crofts, chief executive officer of Mateenbar USA LLC.