Toposens releases ultrasonic echolocation sensor for 3D Collision Avoidance

Munich-based high-tech company Toposens GmbH is officially releasing its new Ultrasonic Echolocation Sensor for 3D Collision Avoidance.

The industrial grade sensor development kit, called ECHO ONE DK, is the next level development based on the company’s proven 3D ultrasonic technology, which mimics a bat’s echolocation techniques.

Unlike existing sensor technologies that can be negatively impacted by lighting conditions or moisture (such as fog), Toposens’ ECHO ONE DK uses echolocation to generate robust, real-time 3D echo location data to guide autonomous systems across a variety of applications. The performance of this 3D ultrasonic sensor is particularly robust in harsh environments (featuring the IP67 protection rating), as it is dirt tolerant and not affected by dust, smoke, and mist.

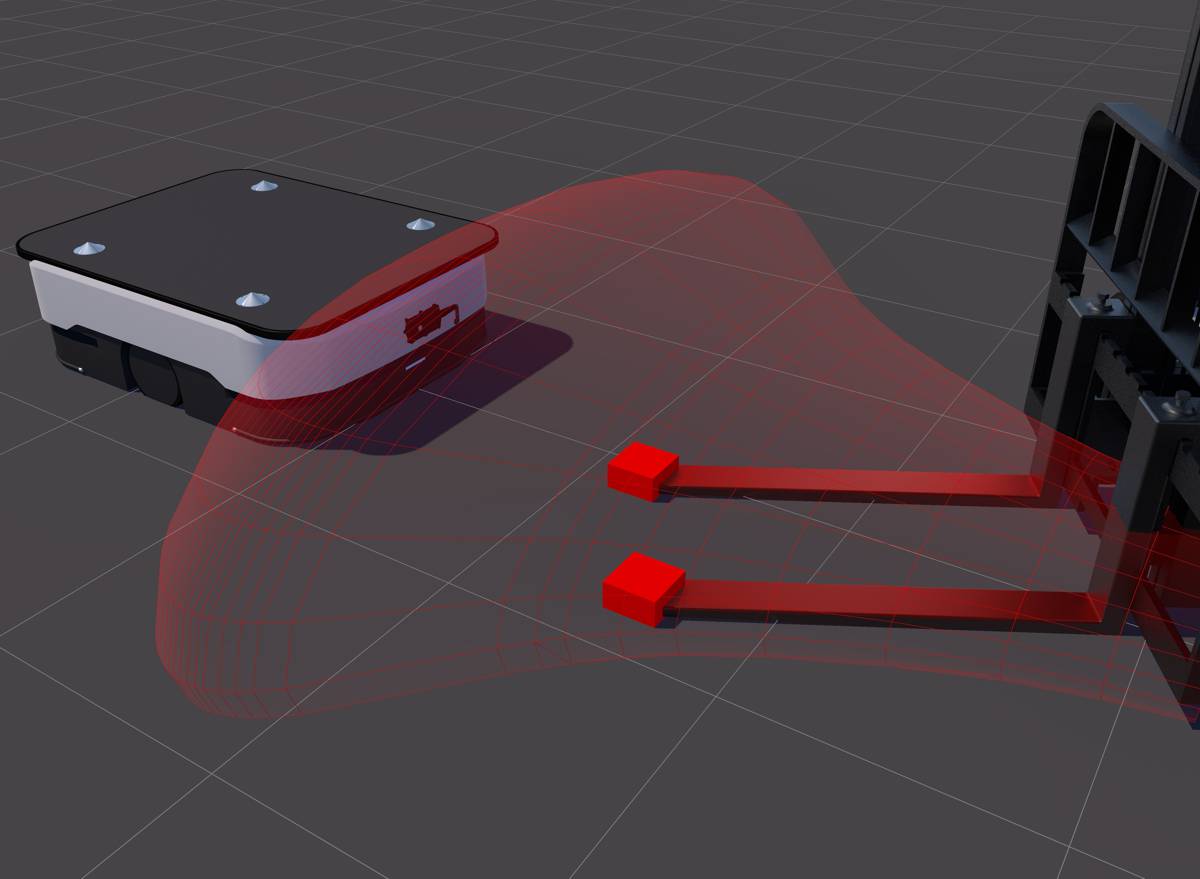

The company, which has also opened an office in Silicon Valley, has a simple goal with its new ECHO ONE DK: Next-Level Robotic Safety. Offering solutions to shortcomings of existing, typically optical range-finding technologies through best-in-class 3D object detection (such as detecting forklifts forks in 3D space), makes the ECHO ONE DK the perfect go-to technology for the development of reliable 3D collision avoidance.

Owing to the unprecedented and unrivalled 3D ultrasonic sensing capabilities, customers can increase efficiency and safety in automated guided vehicles (AGVs) and other robotic systems.

The ECHO ONE DK features 3D multi-object detection of complex and transparent objects in an ultra-short operating range from 20cm up to 3m. It offers an ultra-wide Field-of-View of up to 180° in ultra-short range and up to 110° at 3m. Its low power consumption of 2.2 W supports a longer robot uptime, and it is fully certified according to CE, FCC and IP67 regulation.

For an easy integration, this DK comes with a CAN and USB interface and the following software packages: Toposens Sensor Library (C++-Library), ROS Implementation Package, Cross-Platform Toposens 3D Visualizer.

To ensure the highest possible standard of all hardware and software components integrated into the sensor ecosystem, Toposens is partnering with notable high-tech companies such as Infineon, Murata and Nvidia, which supply various high-class parts including the XENSIVTM MEMS microphones, passive components, and post-processing computation platforms.

“Our biggest asset is our innovative combination of unique hardware configuration and software packages, based on patented 3D and Time-of-Flight algorithms and noise filtering, processing ultrasonic echo data into reliable 3D data”, says Tobias Bahnemann, CEO and Co-Founder of Toposens, and concludes: “With our sensor solution, the high costs of operating accidents can be reduced, improving safety in manufacturing environments, and increasing the ROI of AGV applications.”

There is currently no sufficient solution to the challenges of reliable environment perception in range-finding sensors, especially in 3D ultra-short-range protecting robots from collisions with objects in 3D space. In logistics, AGVs are considered safer and more reliable than traditional transportation methods. Nevertheless, they are still prone to navigation management issues such as deadlocks and collisions (e.g., not detecting forklift forks accurately), which can lead to high repair costs and damaged AGVs, broken cargo, production stoppages and in the worst case, personal injuries.

While the AGV-market is expected to grow to 50% CAGR, AGV-related accidents amount to 100,000 USD plus in damages per factory per year. Thus, there is a valid need for advanced sensor-based safety features to prevent those costly collisions and to increase automation efficiency by minimizing false-positives and deadlocks.

“Our 3D ultrasonic sensor is the answer to this problem by precisely perceiving its environment and reliably detecting accident-causing objects such as forklift forks and even the smallest items lying in the path of an AGV, while yielding robust, light-tolerant data. To reduce accidents to zero, the demand for safety sensors of all kinds is growing. Especially for 3D perception, an area not covered by the typically used 2D safety LiDARs. The in-built, Toposens-own, best-in-class 3D collision avoidance features for added machine safety make it a cost-effective, reliable and efficient solution, which will help your AGV, robot, or other application avoid collisions with all kinds of obstacles, even in the roughest environments, as the IP67 rating proves”, explains Alexander Rudoy, Co-Founder and CTO of Toposens GmbH.