Lafarge in Richmond commits to lower Carbon from Cement by 100 percent

Marking a big shift in helping to reduce CO2 emissions in construction across Western Canada, Lafarge announced today that their Richmond plant will manufacture only OneCem, the company’s lower carbon portland limestone cement for use in materials across BC and the Pacific Northwest.

Lafarge has converted the entire facility to OneCem – ensuring that all cement produced there maximizes reductions. “OneCem is one of our many answers to building sustainably,” shares Brad Kohl, President & CEO of Lafarge in Western Canada. “OneCem offers all the same performance and qualities as standard cements, but with significantly less CO2 emissions.”

Using OneCem in concrete decreases CO2 emissions while ensuring the same level of strength and durability as concrete produced with regular portland cement. “The built environment plays a central role in the transition towards a low-carbon economy,” says Dr. Rob Shogren, Technical Director Cement North America . “We can make concrete more sustainable when we adjust how it is produced and used.”

“This has been a long term goal for our operations,” explains Cory Cannon, VP of Sales and Logistics. “Through collaboration with municipalities, constructors, and engineers, we have encouraged the shift away from standard cements and converting to OneCem since 2011. This commitment means that every product manufactured with OneCem has lower emissions than ever before.”

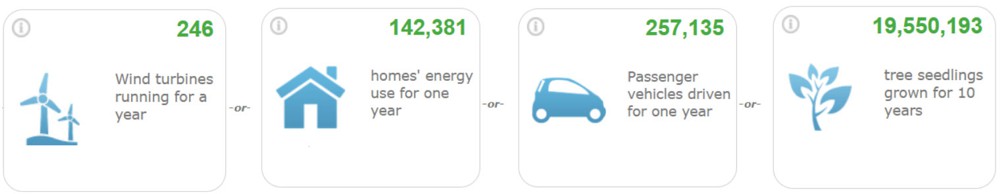

Richmond services a wide range of markets in Canada and has supplied its Western Canadian and Pacific NW customers with OneCem since 2011. Richmond’s OneCem CO2 emissions per tonne are 20% below the national Canadian average for GU cement. Concurrently, it’s also 13% lower than the national average for other PLC cements manufactured in Canada. Since 2011, when Richmond began producing OneCem, “We have eliminated 1,175,000,000 kilograms of CO2 from our atmosphere. This is equivalent to taking a quarter of a million vehicles off our roads for an entire calendar year,” says Cannon.

“The opportunity for North American cities to build sustainably is significant,” shares Kohl. The impact of reducing CO2 emissions in the built environment has been identified as a key driver in reducing climate change. “Collaborating with local government and stakeholders was key to ensuring its uptake in the market, and conversion away from traditional high intensity cement products,” he says. “As industry leaders we want to facilitate access to low carbon cements across Canada, and starting with Richmond is a big step towards making that happen.”