Robotic first with Powerline installation of PLP Conductor Spacers and Bird Diverters

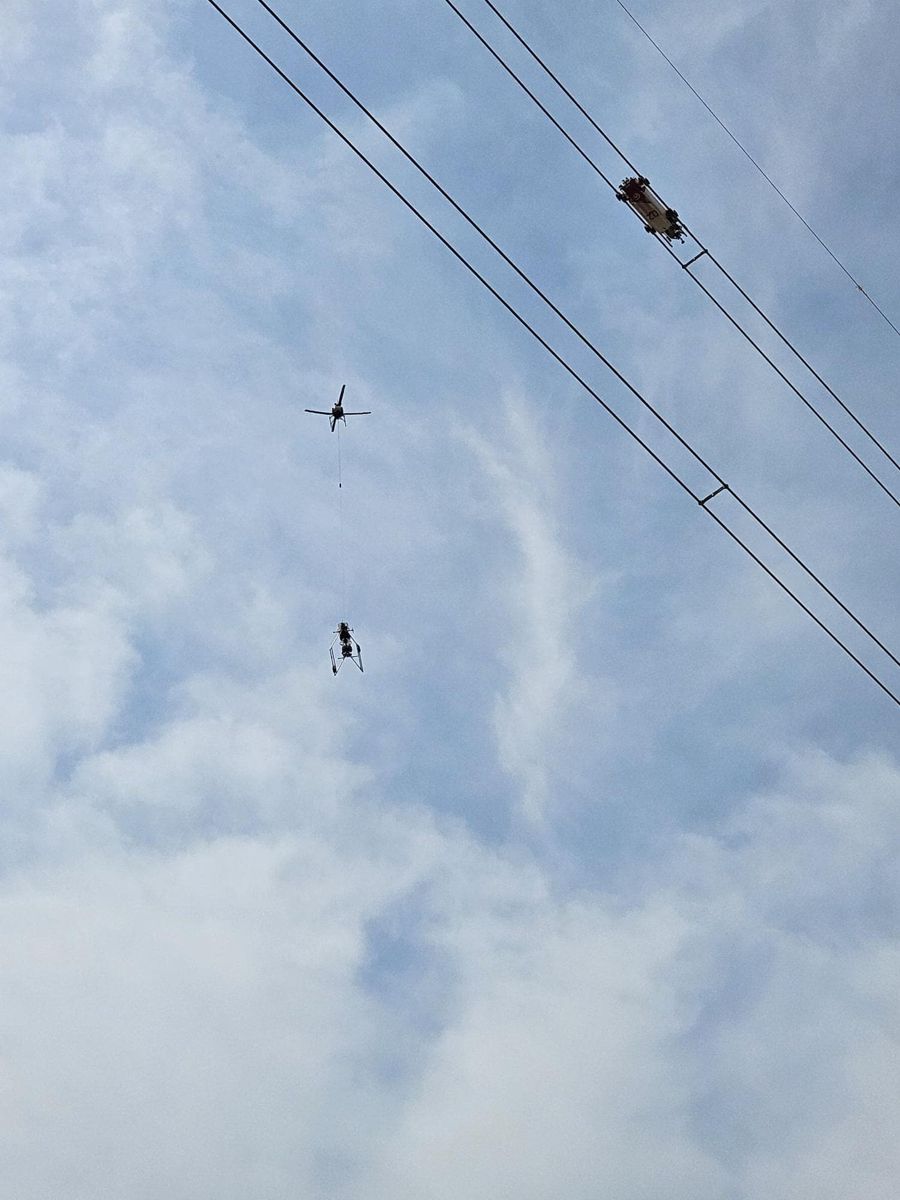

FulcrumAir is proud to announce that the company has completed its portion of the High Banks Wind Project in Kansas using advanced robotic technology to accurately and safely install PLP CUSHION-GRIP® Twin Spacers and BIRD-FLIGHT™ Diverters.

The High Banks Wind Project is Kansas’ largest wind farm. Kiewit constructed the 75-mile 345 kV transmission line across Marshall, Republic, and Washington counties to tie the High Banks Wind Project into the grid.

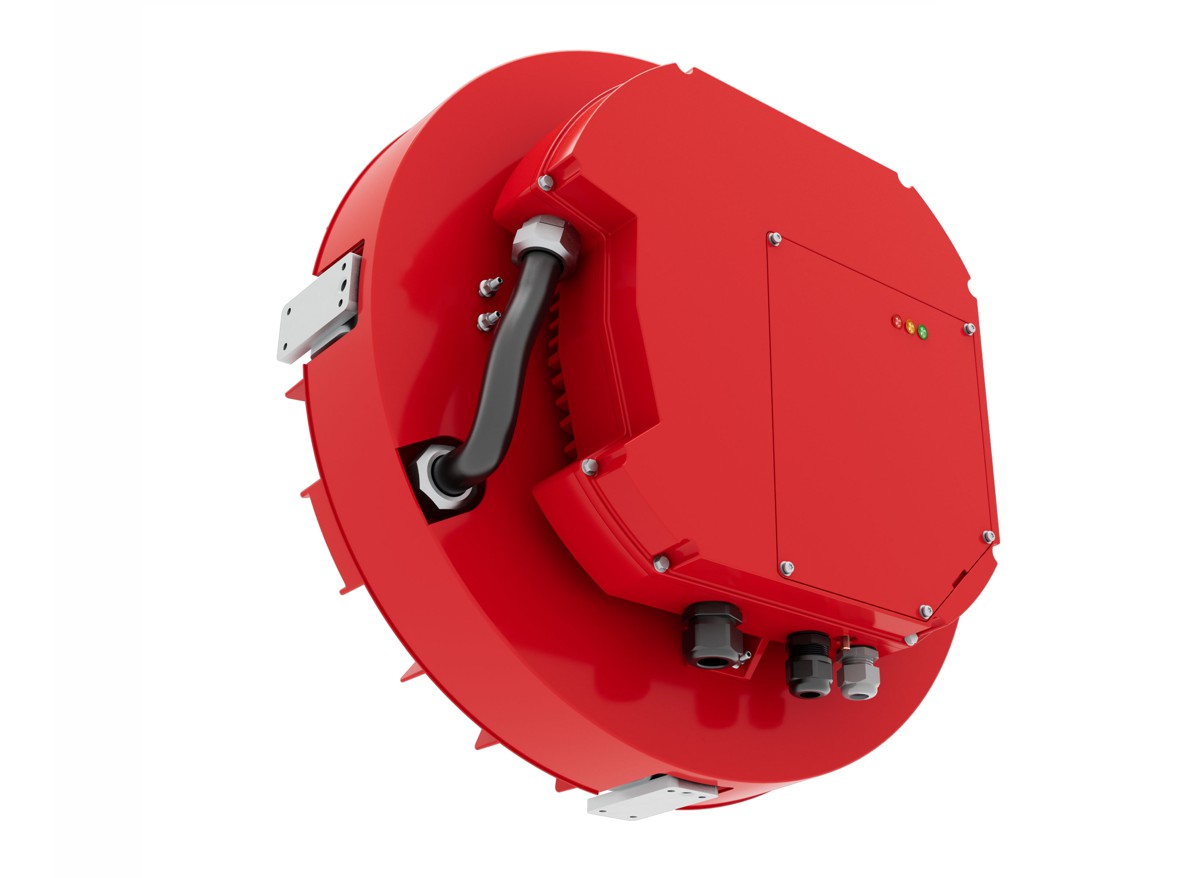

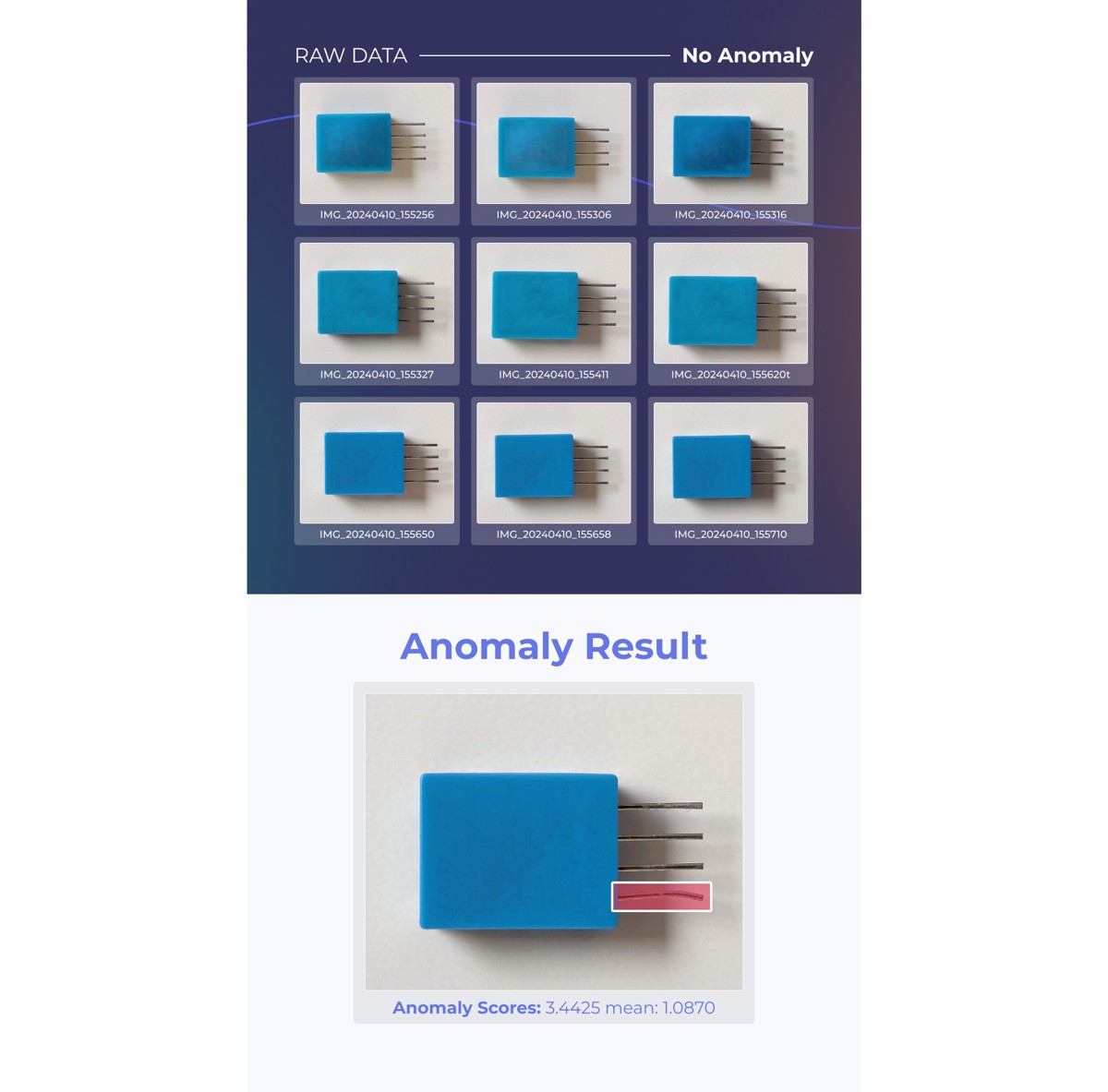

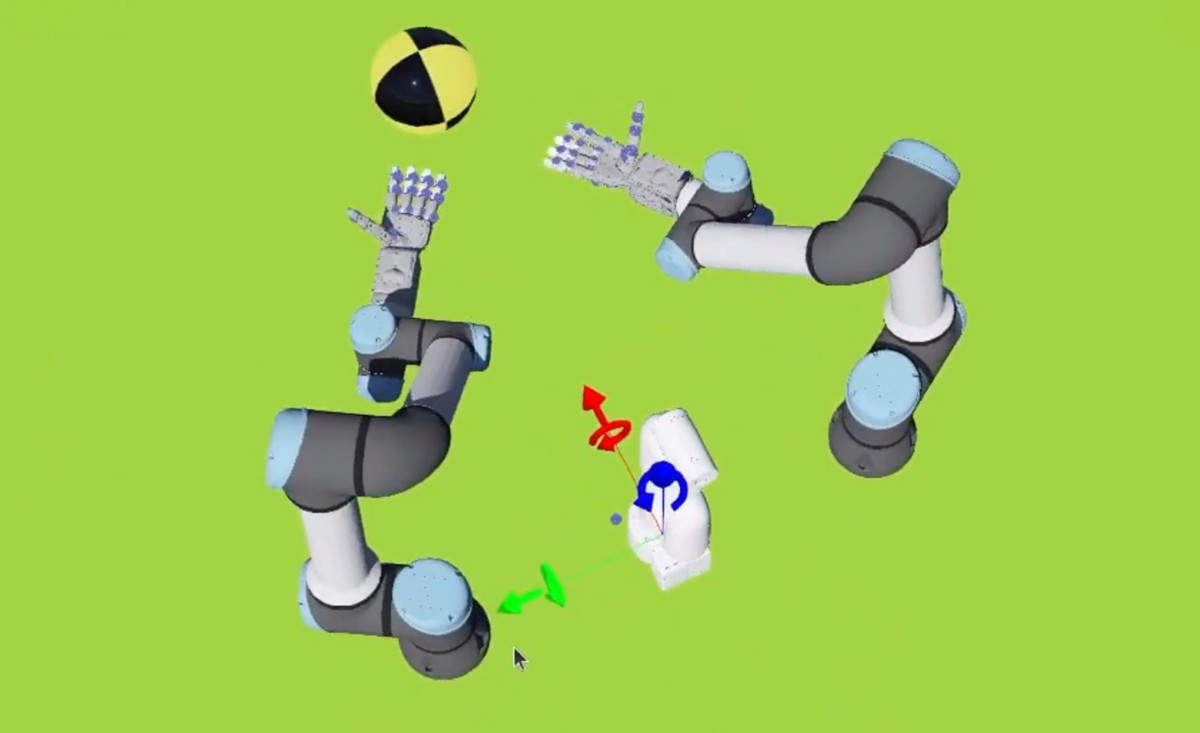

Kiewit contracted FulcrumAir to assist in the construction utilizing its robotic installation methods. For the first time in the world, PLP’s CUSHION-GRIP® Twin Spacers were installed robotically utilizing FulcrumAir’s CSR-18™ robot. PLP’s BIRD-FLIGHT™ Diverters were also installed robotically for the first time using FulcrumAir’s Mini LineFly™.

Patrick Arnell, CEO of FulcrumAir, said: “We are extremely pleased with how our equipment performed on this demanding project. FulcrumAir’s mission is to develop and operate equipment to assist the power line industry with the challenges it faces, including staff shortages, increasing demands for even safer work sites, and efficiency and quality increases.”

A total of over 6,000 twin spacers and nearly 15,000 bird diverters were installed to the exacting specifications required, including the spacing of the BFDs and spacers, the bolt torque of the spacers, and the spacers alignment to the conductors.

“Since our inception over 75 years ago, PLP has prided itself on being an industry leader in every respect. This partnership with FulcrumAir to develop the CSR-18™ robot further illustrates our longstanding commitment to bring the best, most innovative products to every market we serve,” said Ryan Ruhlman, President of PLP. “Not only will the robot improve efficiencies, but it will also greatly improve the safety environment for utility workers around the world. The roboticization of the utility market will continue to expand throughout the next decade, and PLP is excited to lead the way in the transformation.”