Saint-Gobain’s Canadian Kootenay West Gypsum Mine Reaches Full Production

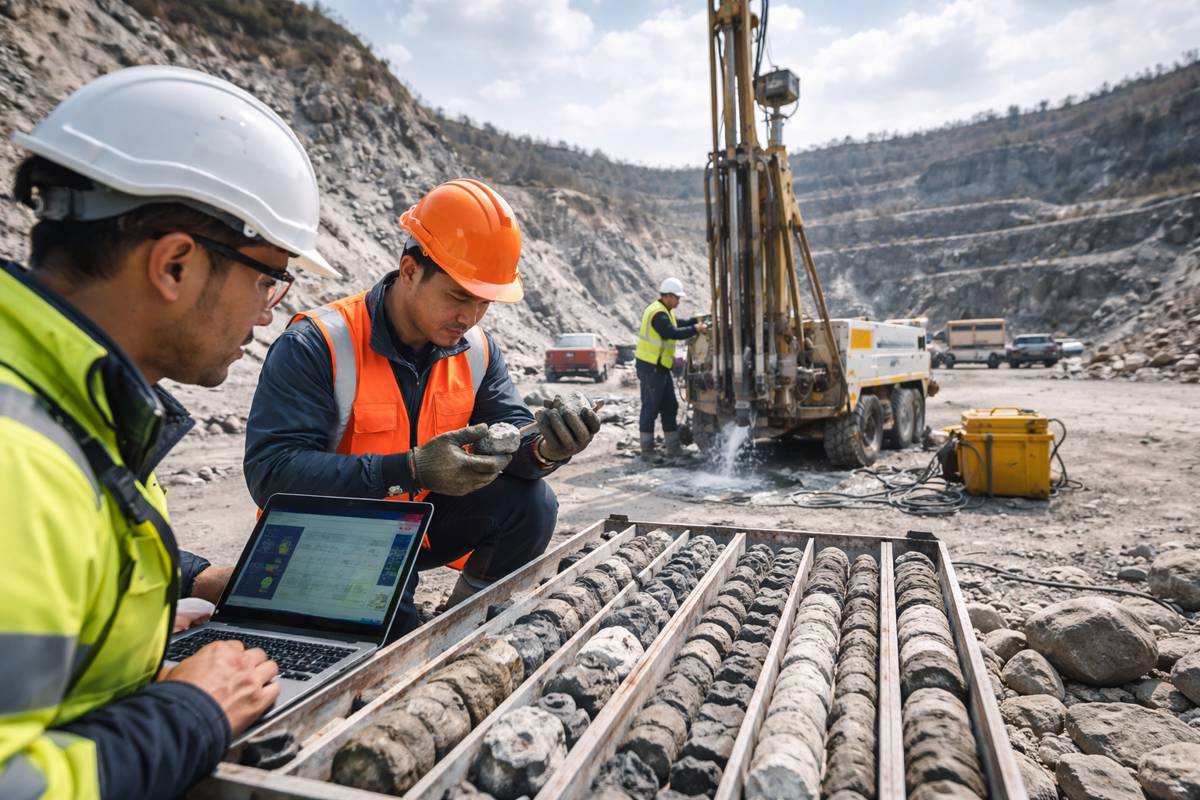

Saint-Gobain Canada has marked a pivotal moment in its Western Canadian operations with the completion and commissioning of the CertainTeed Kootenay West Gypsum Mine near Canal Flats, British Columbia.

With the installation of permanent equipment now finalised, the site officially transitions into full production capacity, reinforcing Saint-Gobain’s long-term commitment to sustainable, localised material sourcing across North America.

The Kootenay West Gypsum Mine is more than just a new source of raw material. It’s a strategic investment designed to strengthen the supply chain for CertainTeed’s wallboard plants in Vancouver and Calgary. The mine will produce an estimated 400,000 tonnes of premium-grade gypsum rock annually, ensuring a reliable, high-quality feedstock for decades to come.

Jean-Claude Lasserre, CEO of Saint-Gobain Canada, shared the company’s enthusiasm: “It is with great pride that we officially launch full operations of our Kootenay West Gypsum Mine in British Columbia, a strategic expansion of our presence in Canada, strengthening our operations to continue meeting the construction market demand. With this new mine, we reinforce our commitment to supply Western Canada with our high-quality CertainTeed products and solutions for decades to come.”

A Strategic Investment in Western Operations

Construction of the Kootenay West Gypsum Mine began in late 2019 and has since become a cornerstone of Saint-Gobain’s $50 million CAD investment strategy in the region. The site currently employs 30 skilled professionals, spanning operations, maintenance, and logistics roles. The mine’s projected operational lifespan of over 40 years underscores the company’s dedication to long-term, responsible resource development.

The mine’s proximity to key manufacturing hubs also enhances supply chain resilience, reducing dependence on external imports and mitigating the risks associated with global market disruptions. In an industry where reliability and quality are paramount, such strategic control of raw materials provides a major competitive edge.

Transition from Windermere to Kootenay West

The development of Kootenay West was initiated to succeed CertainTeed’s Windermere Mine, located near Invermere, British Columbia. As gypsum rock quality requirements evolved, Saint-Gobain sought to ensure its continued ability to produce top-tier wallboard materials. Rather than shuttering Windermere, however, the company took an innovative approach.

The Windermere site will continue operating, supplying gypsum for external clients in the agriculture and cement sectors. This move not only diversifies revenue streams but also extends the operational life of Windermere by an additional 15 years. Such foresight reflects the Group’s balanced approach to industrial growth, prioritising efficiency while maximising the value of existing assets.

Driving Down Carbon Emissions with Smarter Logistics

Sustainability sits at the heart of Saint-Gobain’s global mission, and the next phase for the Kootenay West operation exemplifies this vision. CertainTeed Canada has initiated a permitting process for a new rail loadout project that will dramatically cut transportation distances.

Currently, raw gypsum is trucked over approximately 4.5 million kilometres per year. Once the rail system is operational, that figure will plummet to just 250,000 kilometres, a staggering 94% reduction. This will result in significant decreases in Scope 3 carbon emissions, contributing directly to Saint-Gobain’s corporate goal of achieving net-zero carbon by 2050.

The rail expansion represents a model example of how modern mining operations can align with global sustainability frameworks while maintaining operational efficiency. It’s a clear demonstration of how innovation in logistics can deliver real-world environmental benefits.

Strengthening the Eastern Supply Chain

While Western Canada benefits from the Kootenay West operation, Saint-Gobain’s reach extends across the country. In Nova Scotia, CertainTeed’s Antrim Gypsum Project is moving forward following environmental assessment approval by the Nova Scotia Department of Environment and Climate Change in October 2024.

Over the summer, the company completed a crucial development phase, gathering data for detailed design and permitting. Construction of the Antrim facility is scheduled to begin in 2026, with the mine expected to supply natural gypsum to Eastern Canadian and Northeastern U.S. markets.

By sourcing gypsum closer to its customer base, Saint-Gobain will substantially reduce transport miles and related emissions, aligning its operations with its broader sustainability mission. This project reinforces the company’s commitment to a circular, regionalised supply model that minimises environmental impact while maximising efficiency.

Innovation and Legacy

Founded in 1665, Saint-Gobain is approaching its 360th anniversary in 2025, a testament to its enduring spirit of innovation and adaptation. Today, it stands as a global leader in light and sustainable construction, serving industrial and construction markets with integrated solutions that prioritise energy efficiency, resilience, and performance.

The company’s motto, “Making the World a Better Home,” is more than a slogan, it’s a guiding philosophy. Through its subsidiaries, including CertainTeed, Saint-Gobain designs, manufactures, and distributes advanced materials for both new builds and renovation projects. Its product portfolio spans everything from insulation and roofing to interior systems and façade solutions.

CertainTeed itself employs over 6,900 people across more than 60 manufacturing facilities in the U.S. and Canada. The brand is widely recognised for its expertise in building science, helping architects, contractors, and engineers design spaces that are not only functional but environmentally responsible.

Building the Future Responsibly

From Kootenay West to Antrim, Saint-Gobain’s approach reflects a clear vision: sustainable growth through local empowerment. By investing in regional resources, the company strengthens national supply chains, reduces its carbon footprint, and ensures that future generations benefit from cleaner, smarter construction solutions.

Gypsum, though often overlooked, plays a crucial role in sustainable construction. Its recyclability, abundance, and adaptability make it an essential material for the low-carbon transition. As Saint-Gobain continues to invest in mining, manufacturing, and logistics innovation, it positions itself as a leader not just in construction materials, but in the global journey toward sustainable industry transformation.

A Future Built on Strength and Sustainability

The Kootenay West Gypsum Mine’s transition to full production marks more than just the completion of a construction project. It symbolises the evolution of an industry, one increasingly defined by sustainability, resilience, and innovation.

For Saint-Gobain, this is a step forward in a journey spanning centuries, reaffirming its role as a builder of both homes and hope.