FARO CREAFORM and FARO INSIGHT Redefine Measurement and Scanning

In construction, manufacturing, infrastructure maintenance and public safety, there’s one shared reality that rarely makes the headlines: projects don’t fail because teams lack ambition. They fail because they lack certainty. The difference between a bridge opening on time or stalling for months can come down to whether site teams trust what they’re seeing, whether measurements are defensible, and whether data can move cleanly from field to office without being mangled along the way.

That’s why FARO Technologies and Creaform, both businesses of AMETEK, Inc., have made a structural change that’s bigger than an internal reshuffle. FARO’s 3D Measurement business segment is combining with Creaform to form FARO CREAFORM, a dedicated business unit designed to deliver dimensional measurement solutions with what the company calls “practical certainty”. At the same time, FARO’s reality capture business segment is being refocused into a new unit named FARO INSIGHT, tasked with turning physical environments into usable, shareable intelligence across digital workflows.

It’s a move that recognises how measurement and reality capture are evolving into two distinct, high-value disciplines. One lives and dies on precision, calibration and traceability. The other thrives on speed, usability and scale, capturing complex environments and feeding them into decision-making systems that increasingly look like digital twins, asset registers and predictive maintenance platforms. Separating them doesn’t weaken the portfolio. It clarifies the offer, sharpens accountability, and signals a more deliberate direction for customers who’ve grown tired of fragmented toolchains and awkward handovers.

In plain terms, FARO is betting that the next decade of industrial productivity will belong to organisations that can measure faster, scan smarter, and trust their data enough to act on it.

Why Metrology and Reality Capture Are Now Strategic Infrastructure Tools

For years, the world treated metrology and reality capture as specialist functions. Highly technical, sometimes expensive, often isolated from the daily pressures of getting work finished. That mindset is now outdated. Measurement is becoming operational, not occasional, and reality capture is moving from “nice to have” to “must have” as soon as the work gets complex, remote, regulated, or high-risk.

Across infrastructure, the demands are climbing. Governments and owners expect more rigorous reporting, more transparency, and fewer surprises. In manufacturing, supply chains are still jittery and quality problems have grown more costly. Meanwhile, maintenance teams responsible for aging assets face a hard truth: documentation is often missing, inaccurate, or years out of date. A strong scan, backed by reliable dimensional validation, is often the fastest route to establishing what’s really there.

The real shift, though, is cultural. Projects no longer run on best guesses and heroic improvisation. They run on data, workflows, accountability, and repeatability. That’s where metrology and reality capture meet the same end goal: reducing ambiguity so teams can make decisions that hold up under scrutiny.

This is the wider context in which FARO’s new two-unit structure matters. Rather than trying to be everything to everyone under a single umbrella, it’s drawing a cleaner line between the needs of dimensional measurement and the needs of reality capture ecosystems. It’s a recognition that customers don’t just buy hardware anymore. They buy confidence.

FARO CREAFORM Brings Dimensional Measurement Under One Roof

The centrepiece of the reorganisation is the merger of FARO’s 3D Measurement business segment with Creaform, creating FARO CREAFORM. The intent is straightforward: bring together two established names in portable metrology so industrial customers can access a single, coherent portfolio through a single point of contact.

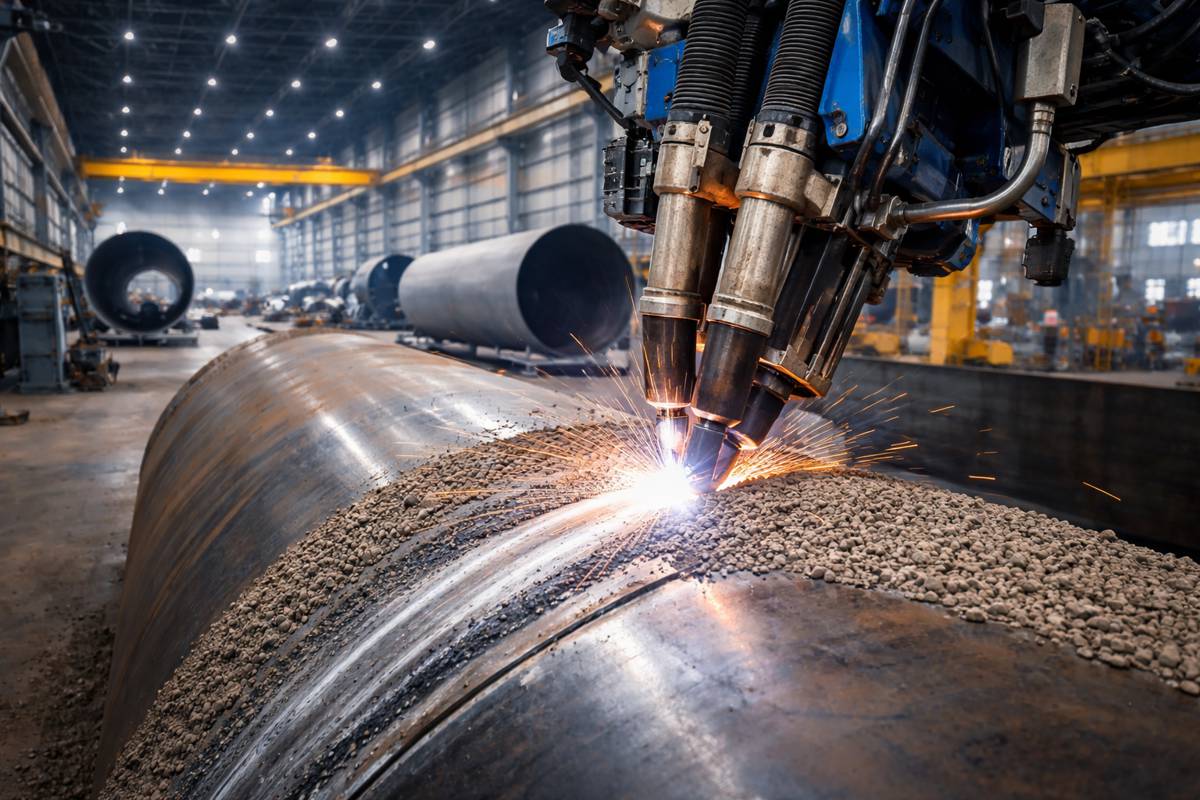

The business unit will be led by Fanny Truchon, with a mission to make metrology “more mobile, usable, and transformative”. Mobility matters because dimensional verification is no longer confined to clean inspection labs. It’s happening on factory floors, in shipyards, in hangars, in depots, and increasingly out in the field where conditions are tough, time is short, and decisions still need to be defensible.

The phrase “portable metrology” can sound niche until it’s placed in the real world. It’s what enables teams to verify alignments during assembly, check tolerances during production, confirm repairs during overhaul, and validate components when supply chains force unexpected substitutions. When accuracy is non-negotiable, portable measurement becomes the difference between a controlled process and a costly dispute.

Truchon framed the ambition clearly, saying: “FARO CREAFORM is more than a consolidation. By combining the strength of two leaders, we’re opening possibilities that will empower industries to move from hindsight to foresight. FARO CREAFORM aims to become the undisputed leader in portable metrology”.

The emphasis on “hindsight to foresight” is telling. Metrology is shifting from being a tool for diagnosing problems after they happen to becoming part of a proactive control loop. Measured data can now feed directly into quality systems, digital work instructions, automated inspection routines, and longer-term analytics. This is where measurement starts influencing planning rather than simply confirming outcomes.

What the Combined Portfolio Means for Quality, Maintenance and Production Teams

FARO CREAFORM is headquartered across Lévis, Québec, Canada and Lake Mary, Florida, USA, positioning the combined unit at the intersection of North American manufacturing, aerospace, automotive, and industrial R&D networks.

FARO brings roots dating back to 1981, with a track record built around portable measurement arms, laser trackers, and reality capture technologies. Creaform, founded in 2002 in Lévis, built its reputation on handheld 3D scanning and automated inspection, supporting professionals across automotive, aerospace, manufacturing, and research.

Together, the unit is intended to support quality, production, maintenance and design teams who need measurement that fits modern working realities. That means less downtime waiting for specialists, fewer delays transporting parts to inspection facilities, and more confidence in decisions made at speed.

There’s also a commercial logic to consolidation. Industrial organisations are trying to reduce the number of vendors they depend on, not increase it. The more tools a customer buys from different sources, the more integration work they carry internally, and the more difficult it becomes to establish a single source of truth for what’s been measured and what’s been verified.

By offering a combined portfolio under one structure, FARO CREAFORM is leaning into this desire for simplification. For contractors and asset owners, it’s not just about measurement accuracy. It’s about procurement clarity, support consistency, and workflow continuity. At scale, those are often the real differentiators.

FARO INSIGHT Targets Reality Capture at Scale for Digital Twin Workflows

While FARO CREAFORM focuses on precision measurement, the newly defined FARO INSIGHT business unit focuses on what happens when reality needs to be digitised quickly and reliably, often in complex environments. FARO INSIGHT will be led by Dietmar Wennemer, working alongside Virtek Vision, and will operate as a dedicated engine for reality capture solutions.

This is a significant acknowledgement that reality capture has grown into its own ecosystem, with expectations that extend far beyond the initial scan. The value isn’t only in capturing point clouds or images. It’s in converting data into insight, managing it securely, sharing it efficiently, and keeping it trusted over time.

FARO INSIGHT’s role is to move teams “from field data to impact”, supporting seamless capture, point cloud conversion, and data management and sharing. The organisation specifically highlights digital twin workflows across AEC&O, public safety, and geospatial, which is a broad and telling scope. It suggests FARO sees reality capture as a foundational layer underpinning both the built environment and broader spatial intelligence workflows.

Wennemer summed up the ethos, stating: “FARO INSIGHT’s approach is simple: we want to digitize the world. Our hardware and software solutions reduce ambiguity to help track building progress, document changes, digitize crime scenes, structures, mines, forests, and landscapes to provide insights customers can build on”.

It’s a wide list, and deliberately so. Reality capture is now used across highways and bridges, industrial plants, utilities, tunnels, ports, and mines. It’s also used for incident documentation and investigations where accuracy and defensibility matter just as much as speed. Whether it’s progress tracking on a jobsite or capturing a complex environment in difficult conditions, the core promise remains the same: what’s captured becomes a trustworthy reference point.

Reality Capture Is Becoming the Glue Between Design, Build and Operate

There’s a reason reality capture is showing up in more board-level conversations. Infrastructure owners are no longer content to treat construction and operations as disconnected phases. They want continuity, and they want data that carries forward.

Laser scanning and reality capture play a practical role in this transition. A scan can validate that work has been delivered as designed. It can document what’s changed in the field. It can help teams plan retrofits without hazardous exploratory work. It can also reduce clashes, rework, and disputes, especially when multiple parties are working off different versions of drawings.

Reality capture is also increasingly used to establish baselines for asset condition and performance. The ability to “see” and measure environments at scale changes how maintenance is scheduled, how risks are assessed, and how upgrades are planned. For public agencies managing thousands of structures and kilometres of roads, this isn’t futuristic thinking. It’s becoming standard operating practice.

By positioning FARO INSIGHT as a dedicated unit, FARO is signalling it wants to own a larger part of this lifecycle conversation. Not just capturing, but enabling teams to manage and share data in a way that supports long-term operational decisions. In a world moving towards digital twins and connected infrastructure management, that’s not a small ambition.

A Strategy Built Around Trust, Continuity and Long-Term Growth

The reorganisation is described as being designed to “deliver greater value to customers, accelerate innovation, and create synergies that support growth and long-term growth”. While corporate language tends to blur into the background, the customer-facing intent here is clearer than most.

FARO and Creaform are framing the change around continuity and trust, with an emphasis on providing clear, timely information and maintaining customer confidence. That matters because metrology and reality capture are used in environments where mistakes carry real consequences: failed inspections, rework, production delays, safety risks, and contractual disputes.

Both FARO CREAFORM and FARO INSIGHT operate as business units within AMETEK, Inc., described as a global provider of industrial technology solutions serving attractive niche markets with annual sales of over $7.0 billion. In practical terms, that backing suggests investment capacity and long-term stability, factors that matter for organisations purchasing systems intended to run for years, not months.

The story here isn’t that FARO has invented a new technology overnight. It’s that it’s reorganised to better match how customers now use measurement and scanning in their day-to-day workflows. That alignment between structure and real-world demand is often where meaningful innovation begins.

What This Means for Construction, Infrastructure and Industrial Decision-Makers

For construction and infrastructure leaders, this announcement is an indicator of where the market is going. Measurement and reality capture are no longer isolated specialist services brought in only when something goes wrong. They are becoming embedded tools for preventing problems in the first place.

For manufacturers and maintainers, the implications are similarly direct. Faster inspection, portable measurement, and scalable capture workflows all contribute to shorter shutdowns, higher quality output, and more efficient maintenance cycles. Over time, that improves productivity and reduces risk, not through grand promises but through small, dependable improvements applied repeatedly.

Ultimately, FARO’s split into two specialised units speaks to a wider truth about the digital industrial economy. Data is only valuable when it’s trusted. And trust, in industries that live in millimetres and tolerances, is earned through repeatable measurement, dependable capture, and workflows that don’t fall apart when they leave the lab or the office.

With FARO CREAFORM focused on dimensional certainty and FARO INSIGHT focused on trusted reality intelligence, the company is betting that the next wave of progress won’t be driven by more information. It’ll be driven by better information, delivered in forms teams can actually use.