AI Skills Platforms Are Redefining Industrial Robotics at Scale

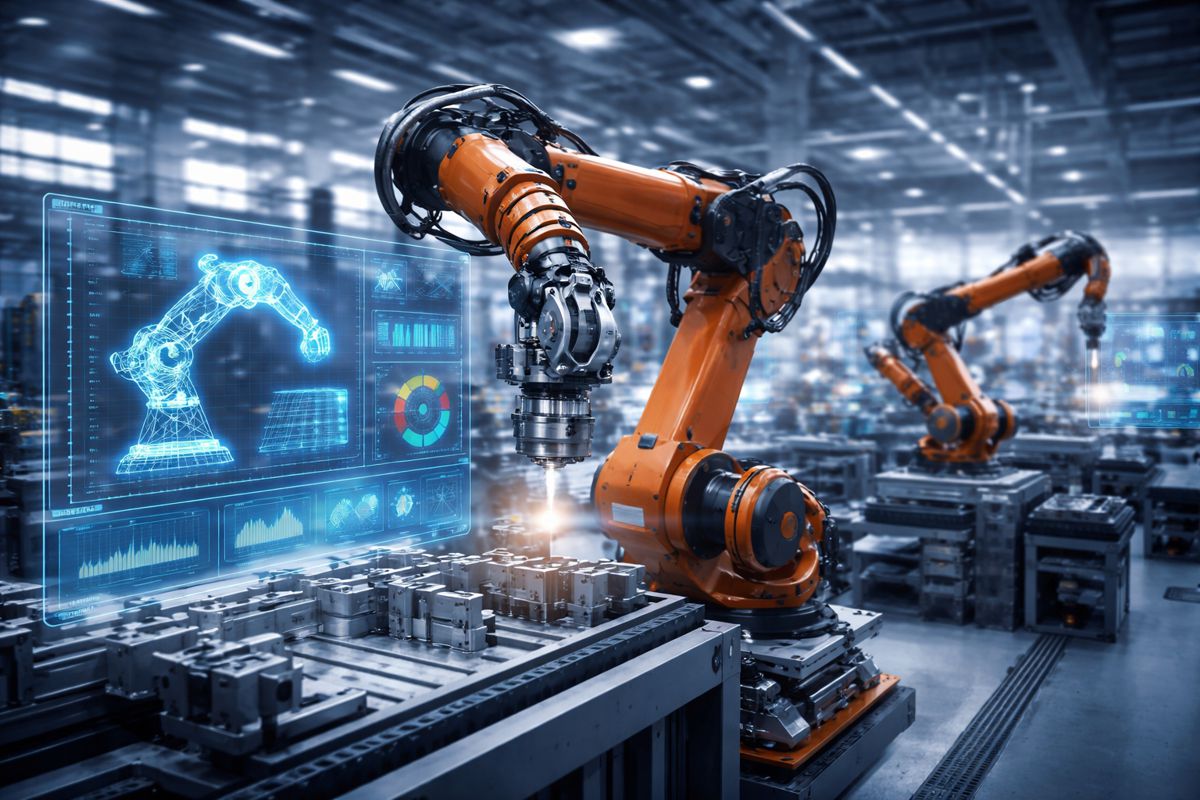

The race to make industrial robots more flexible, intelligent and commercially viable has taken a decisive turn. As manufacturers across Europe and North America grapple with labour shortages, volatile supply chains and the relentless pressure to improve margins, the next competitive frontier is no longer hardware alone. It is software defined intelligence.

Trener Robotics has now secured $32 million in Series A funding to accelerate development of its robot agnostic AI skills platform, Acteris. The round was co-led by Engine Ventures and IAG Capital Partners, with participation from Cadence and Geodesic Capital through Nikon’s NFocus Fund. With total funding now exceeding $38 million, the company is positioning itself not as another robotics hardware supplier, but as a foundational intelligence layer for physical automation.

The significance of this development extends well beyond one startup’s funding milestone. It reflects a structural shift in the global construction and manufacturing ecosystem, where the limitations of traditional robot programming are increasingly incompatible with high mix, high variability production.

From Rigid Code to Conversational Automation

For decades, industrial robotics has been synonymous with precision and repetition. Major robot brands such as ABB, Universal Robots and FANUC have deployed millions of robotic arms worldwide. Yet most remain confined to tightly controlled, single purpose environments, programmed through specialist code and often requiring system integrators for even minor task adjustments.

That rigidity has become a bottleneck. Modern factories are increasingly characterised by short production runs, product customisation and frequent changeovers. In construction equipment manufacturing, automotive supply chains and off highway machinery production, lines rarely stay static for long. Traditional procedural programming struggles to keep up.

Trener Robotics’ platform, Acteris, addresses this constraint by allowing operators to describe tasks in natural language. Instead of writing detailed motion scripts, users articulate objectives conversationally. The system translates those instructions into executable automation, supported by simulation and real time feedback. In effect, it shifts robot programming from code centric to intent driven.

Dr. Asad Tirmizi, Co Founder and CEO of Trener Robotics, described the shift: “For decades, industrial robotics has been limited by dynamic complexity, confining millions of robotic arms to repetitive, single-purpose tasks in highly controlled environments. We’re fundamentally changing this – transforming robots into intelligent, adaptable teammates by replacing procedural programming with a control system that supports a growing library of production-ready skills. Our go-to-market strategy empowers systems integrators and OEMs with a robot AI skills platform for deploying and controlling robots across diverse industrial environments.”

Physical AI Moves from Research to Shop Floor

The broader industry context reinforces why this matters. According to data from the International Federation of Robotics, global robot installations have reached record levels in recent years, yet deployment remains concentrated in automotive and electronics sectors. Small and medium sized manufacturers have often struggled to justify the cost and complexity of automation.

At the same time, market research indicates that flexible automation solutions are expanding at a compound annual growth rate of approximately 14.3 percent, driven by labour shortages, reshoring strategies and escalating operational costs. In Europe in particular, demographic trends are shrinking the industrial workforce. In the United States, manufacturers report persistent hiring challenges for skilled production roles.

Physical AI, combining vision, language, haptics and motion control, promises to unlock automation in environments previously considered too complex or variable. Acteris is trained on visual, haptic, language and action data, enabling robots to adapt in real time to changing parts and unstructured conditions. That capability has long been a research ambition, but translating it into reliable production systems has proved difficult.

By positioning itself as robot agnostic and compatible with existing equipment, Trener Robotics is targeting a pragmatic route to market. Manufacturers are unlikely to replace entire fleets of installed robots. A software layer that enhances current hardware offers a more commercially attractive path.

An Intelligence Layer for the Factory Stack

Strategic backing from Cadence and Nikon highlights a deeper trend: the convergence of robotics, advanced simulation and precision vision technologies. Cadence, known globally for electronic design automation, plays a critical role in high performance compute and simulation infrastructure. Nikon, through its NFocus Fund, brings expertise in advanced optics and industrial precision systems.

Their participation underscores the idea that robotics is becoming increasingly software defined. As digital twins, AI models and high fidelity simulation integrate into production planning, the factory stack is evolving. Robots are no longer isolated electromechanical units. They are nodes within a broader computational ecosystem.

Acteris incorporates high fidelity simulation, natural language interfaces and real time dashboards for performance monitoring. It includes intelligent collision avoidance and safety features designed to mimic human common sense, along with vision based part identification under adverse conditions. In industries such as heavy equipment manufacturing or component machining, where tolerances are tight and safety is paramount, these features are commercially significant.

Reed Sturtevant, General Partner at Engine Ventures, commented on the company’s trajectory: “When we co-led Trener Robotics’ seed round, we saw a team with a clear vision to solve one of automation’s biggest bottlenecks. Their execution and ability to rapidly scale has been remarkable. This traction positions Acteris as the intelligence layer for physical automation and reinforces their ability to scale through partner-led distribution.”

High Mix Production and the SME Opportunity

The implications for small and mid sized enterprises are particularly noteworthy. CNC machine tending, assembly, inspection and material handling tasks often require frequent reconfiguration. Historically, SMEs have been cautious about robotics due to integration complexity and specialist skill requirements.

Dennis Sacha, Partner at IAG Capital Partners, framed the opportunity: “Industrial automation is at an inflection point, with Trener Robotics well-positioned as a platform accessible to manufacturers of all sizes, creating a repeatable path for expanding capabilities beyond CNC machine tending. This is precisely what small and mid-sized enterprises globally need to compete as AI redefines manufacturing.”

In practical terms, a conversational interface reduces reliance on scarce robotics programmers. System integrators can deploy solutions more rapidly, while shop floor operators gain greater autonomy. For construction machinery suppliers, infrastructure component manufacturers and industrial fabricators, this lowers the barrier to entry.

Furthermore, as governments across Europe and North America pursue industrial competitiveness strategies, including support for advanced manufacturing and digital transformation, platforms that promise rapid return on investment are likely to attract policy attention. Automation is no longer optional in many sectors. It is increasingly tied to resilience and strategic autonomy.

Leadership Rooted in Robotics Research

Trener Robotics was co founded in 2024 by Dr. Asad Tirmizi and Dr. Lars Tingelstad, both with extensive backgrounds in robotics and automation research. Tirmizi previously worked at Vicarious, a robotics company later acquired by Google, and contributed to robotics and haptics initiatives at ByteDance. Tingelstad served as an Associate Professor of Robotic Production at NTNU.

Their combined experience reflects a blend of academic research and commercial deployment. That combination has often been decisive in robotics, where bridging the gap between laboratory prototypes and industrial reliability remains one of the sector’s greatest challenges.

Industry recognition has followed quickly. In late 2024, Trener Robotics was selected as winner of the ABB AI Startup Challenge, reinforcing its relevance to established robotics players. The company also received the Machine Tool Innovation Award at EMO Hannover, one of the world’s largest machining trade shows, signalling that its approach resonates with traditional manufacturing audiences as well as technology investors.

What This Means for Construction and Infrastructure

While the immediate focus is manufacturing, the ripple effects extend into the construction and infrastructure supply chain. Heavy equipment production, prefabrication, modular construction components and specialist metal fabrication all rely on flexible automation.

As construction shifts toward greater industrialisation, with off site manufacturing, robotics in precast facilities and automated rebar processing, the need for adaptable robotic systems becomes acute. Platforms capable of handling part variability, changing workflows and non uniform materials could significantly improve throughput and quality control.

In addition, real time production dashboards and simulation tools align with the broader digitisation of infrastructure delivery. As digital twins become embedded in asset lifecycle management, from design through to maintenance, physical automation systems must integrate seamlessly into data driven workflows.

In short, the emergence of AI driven skills platforms represents more than a technical upgrade. It signals a maturing phase in robotics where intelligence, rather than hardware alone, defines competitive advantage. For manufacturers serving the global construction and infrastructure sectors, that shift may prove decisive in the decade ahead.