Microfluidic Breakthrough Could Transform On Site Environmental Testing

Environmental monitoring has long wrestled with an inconvenient truth. The samples that matter most, river sediments after heavy rain, industrial discharge mixed with soil, wastewater carrying food residues, are rarely pristine. They’re messy, particulate-laden and difficult to process. Yet regulatory thresholds are tightening, particularly for trace pollutants such as per- and polyfluoroalkyl substances and pharmaceutical residues. Analytical precision is no longer optional. It’s mission critical.

Against that backdrop, researchers at the Korea Research Institute of Chemical Technology have unveiled a microfluidic analytical platform that could reshape how environmental samples are prepared and analysed. Working alongside Professor Jae Bem You’s group at Chungnam National University, the team has developed a trap-based microfluidic device capable of directly extracting target pollutants from solid-containing samples without filtration or traditional pretreatment.

Published as a cover article in ACS Sensors in December 2025, the research points towards faster, more compact and potentially automatable environmental testing systems. For infrastructure operators, utilities, regulators and industrial site managers, that’s more than an academic footnote. It signals a shift in how contamination could be monitored in the field.

Why Pretreatment Has Been the Weak Link

Conventional environmental analysis is built around a sequence of steps that haven’t changed dramatically in decades. When solids such as sand, soil or organic residues are present, samples typically undergo filtration, separation and preconcentration before chemical analysis. Liquid–liquid extraction has been widely used to isolate trace compounds from aqueous samples.

On paper, the approach is sound. In practice, it’s cumbersome. Filtration can unintentionally remove trace-level target pollutants along with particulate matter. That’s particularly problematic for compounds that adsorb onto fine solids. The result can be under-reporting of contamination levels, precisely when regulators and communities need clarity.

Moreover, traditional liquid–liquid extraction consumes significant solvent volumes and is difficult to automate. Liquid–liquid microextraction has reduced solvent use and system size, but it still struggles with samples containing suspended solids. Filtration remains an obligatory step. Each additional stage adds time, cost and risk of analytical error.

For sectors linked directly to public health, drinking water providers, wastewater utilities, food processors and pharmaceutical manufacturers, those limitations are more than procedural annoyances. They represent bottlenecks in compliance, traceability and rapid response.

A Microfluidic Architecture That Bypasses Filtration

The joint research team addressed the issue not by refining filtration, but by eliminating it from the workflow. Their solution is a trap-based microfluidic device that physically confines a small extractant droplet within a microchamber. Adjacent to this chamber, a microchannel allows the sample solution to flow continuously.

The geometry is deceptively simple. The extractant droplet remains immobilised in its chamber, while the bulk sample moves past it. As the liquid sample flows, target analytes transfer selectively into the extractant through rapid mass transfer. Solid particles, meanwhile, continue through the channel without interfering with the extraction zone.

After extraction, the droplet can be retrieved and subjected to downstream analytical methods such as high-performance liquid chromatography. By integrating confinement, extraction and sample handling into a single microfluidic structure, the device effectively compresses multiple pretreatment steps into one controlled process.

Dr. Ju Hyeon Kim of KRICT underscored the operational implications: “integrating multiple pretreatment steps into a single process offers substantial advantages for on-site analysis and automated systems,”

That remark points squarely at the infrastructure opportunity. Compact, modular and potentially field-deployable systems could be embedded in monitoring stations, industrial discharge outlets or even mobile inspection units.

Detecting PFAS and Pharmaceuticals Under Real World Conditions

To validate the platform, the researchers targeted two high-profile contaminants. The first was perfluorooctanoic acid, a representative PFAS compound. PFAS chemicals have become a global regulatory priority, with increasing restrictions in the European Union, the United States and parts of Asia due to persistence and potential health impacts.

Perfluorooctanoic acid was successfully detected within five minutes using the microfluidic platform. That detection speed matters. Rapid screening reduces lag between sampling and response, a crucial factor in managing contamination events or assessing compliance at industrial sites.

The second target was carbamazepine, an anticonvulsant pharmaceutical frequently detected in wastewater and surface waters. Pharmaceutical residues are increasingly recognised as emerging contaminants, particularly in regions where wastewater treatment plants are not optimised for micropollutant removal.

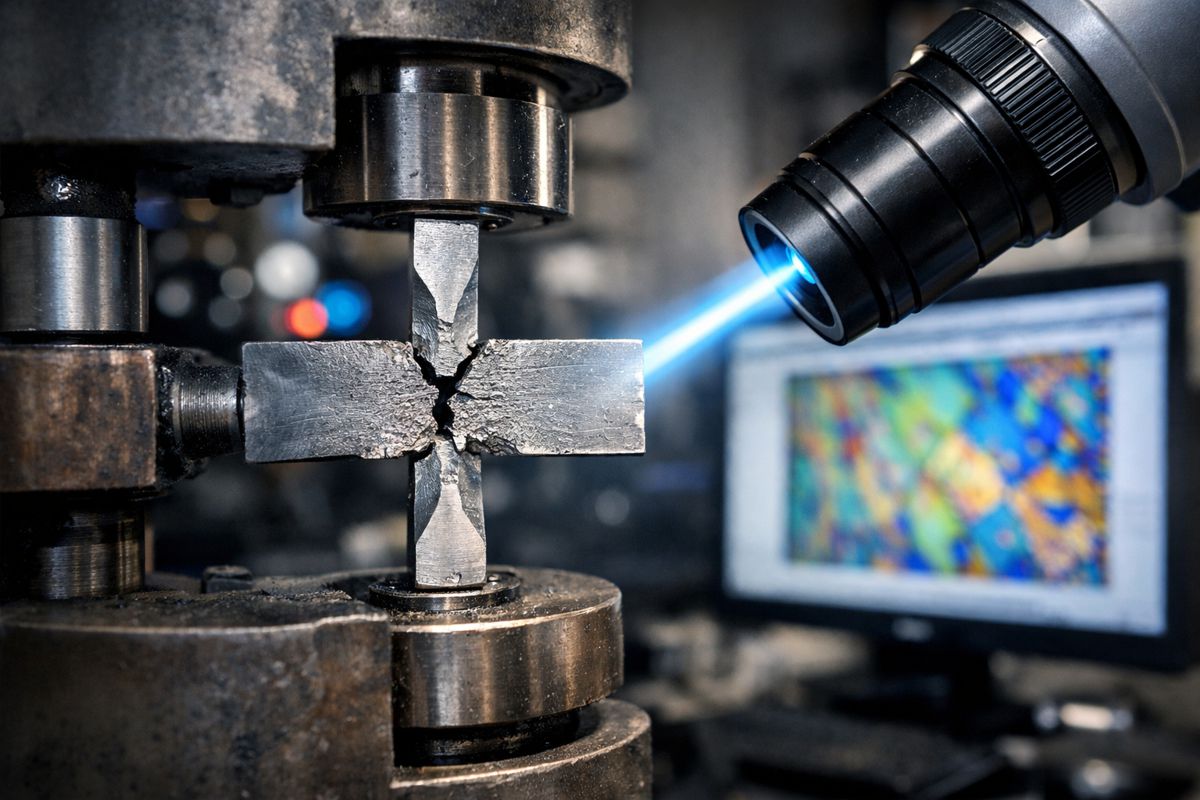

In a notable demonstration, carbamazepine was extracted directly from sand-containing slurry samples without filtration. High-performance liquid chromatography clearly identified the compound after microfluidic extraction. That’s a practical milestone. Slurry samples resemble real environmental matrices far more closely than filtered laboratory-grade solutions.

The ability to handle particulate-laden samples without loss of analytical reliability strengthens the case for in situ environmental diagnostics. In river monitoring after storms, construction site runoff testing or landfill leachate assessment, solids are the rule rather than the exception.

Implications for Infrastructure and Public Health

Environmental monitoring is increasingly intertwined with infrastructure resilience. Climate change is intensifying rainfall events, mobilising sediments and contaminants into water bodies. At the same time, regulators are tightening thresholds for micropollutants. Utilities and infrastructure operators must therefore measure more compounds, more often, and under more challenging sampling conditions.

The proposed microfluidic platform addresses three strategic pressures simultaneously. First, it reduces solvent consumption, aligning with greener laboratory practices and lower operational costs. Second, it shortens analysis time, enabling quicker decision-making. Third, it enhances reliability in complex sample matrices.

For drinking water utilities, accurate detection of PFAS and pharmaceutical residues under turbid conditions is critical. For construction and infrastructure projects, especially those near sensitive watercourses, reliable monitoring supports environmental compliance and community trust. For policymakers, technologies that enable decentralised or automated monitoring systems can strengthen regulatory frameworks without disproportionately increasing cost burdens.

KRICT President Young-Kuk Lee highlighted the public health dimension: “this technology can enhance the reliability of environmental and food safety analyses that directly impact public health.”

That link between analytical chemistry and societal outcomes is often overlooked. Yet in practice, every regulatory limit rests on the credibility of the measurement behind it.

Microfluidics in the Broader Analytical Landscape

Microfluidic technologies have gained traction over the past two decades in biomedical diagnostics, lab-on-a-chip systems and chemical sensing. Their appeal lies in precise fluid control at microlitre scales, reduced reagent consumption and integration potential with automated platforms.

The trap-based configuration introduced by the KRICT and Chungnam National University team extends those advantages to environmental and industrial analysis. By physically isolating the extractant droplet while maintaining continuous sample flow, the system sidesteps a longstanding obstacle in microextraction.

If scaled and engineered for durability, such platforms could be integrated into remote monitoring units powered by solar panels, deployed in agricultural runoff zones or installed at industrial outfalls. Coupled with digital reporting systems and IoT connectivity, microfluidic pretreatment could form part of a broader smart environmental monitoring network.

That vision aligns with global trends towards digital twins of infrastructure systems and real-time environmental dashboards. Data quality is the foundation of those models. Without reliable sample preparation, even the most sophisticated analytics fall short.

From Laboratory Demonstration to Field Deployment

The research was supported by the KRICT Core Research Program, the National Research Foundation of Korea and the Korea–Switzerland Innovation Program. Institutional backing reflects recognition that analytical innovation underpins regulatory, industrial and environmental strategy.

Still, translating a laboratory prototype into a rugged field-ready system will require further engineering. Microfluidic channels must withstand variable temperatures, pressure fluctuations and potentially corrosive samples. Integration with portable analytical instruments will be key.

Yet the direction of travel is clear. As environmental standards evolve, the analytical bottleneck must shrink. Devices that combine solid tolerance, rapid extraction and compatibility with established analytical techniques represent a logical next step.

Founded in 1976, the Korea Research Institute of Chemical Technology has positioned itself as a national centre for chemical, materials and environmental science. With this development, it has contributed a practical solution to a problem that has long complicated environmental compliance and pollution assessment worldwide.

For infrastructure stakeholders navigating stricter environmental regimes and rising public scrutiny, that’s a development worth watching closely. Cleaner data leads to clearer decisions. And in environmental management, clarity is everything.