New Holland wins SIMA 2019 Innovation Award for Combine Feed Roll Reverser

The international jury panel of agricultural experts of the SIMA 2019 Innovation Awards bestowed the Bronze Medal to New Holland’s Dynamic Feed Roll (DFR) Reverser on the CR combine.

This innovative feature enables the operator to clear blockages of the Dynamic Feed Roll from the cab, saving considerable time and making the most of the massive productivity of the highest-capacity combine in the world. This new feature adds to the existing Header and Feeder Reverser and the Concave Overload Protection system, to provide even better protection from crop overload.

Lars Skjoldager Sørensen, Head of Harvesting Product Line, said: “We are delighted with the recognition of this innovative feature, which addresses the challenge of maximizing up-time, one of the most important factors in combine operations. A blockage can always happen, and customers don’t want to have to leave the cab to clear it, wasting precious time. With our DFR Reverser, they can do it very quickly without leaving their seat.”

The benefits of the DFR Reverser for customers is not only the convenience of clearing blockages from the cab, but most importantly the dramatic reduction in the time it takes to complete the operation, from 2 hours to 10 minutes. The cost to a harvesting operation with a high-capacity combine such as the CR9.90 with tractor and cart can add up to 600 to 800 € per hour, with 50 tons less harvested based on 5-6 ha/hour and 8-10 tonnes/ha. This means a significant benefit to the customer’s productivity and profitability.

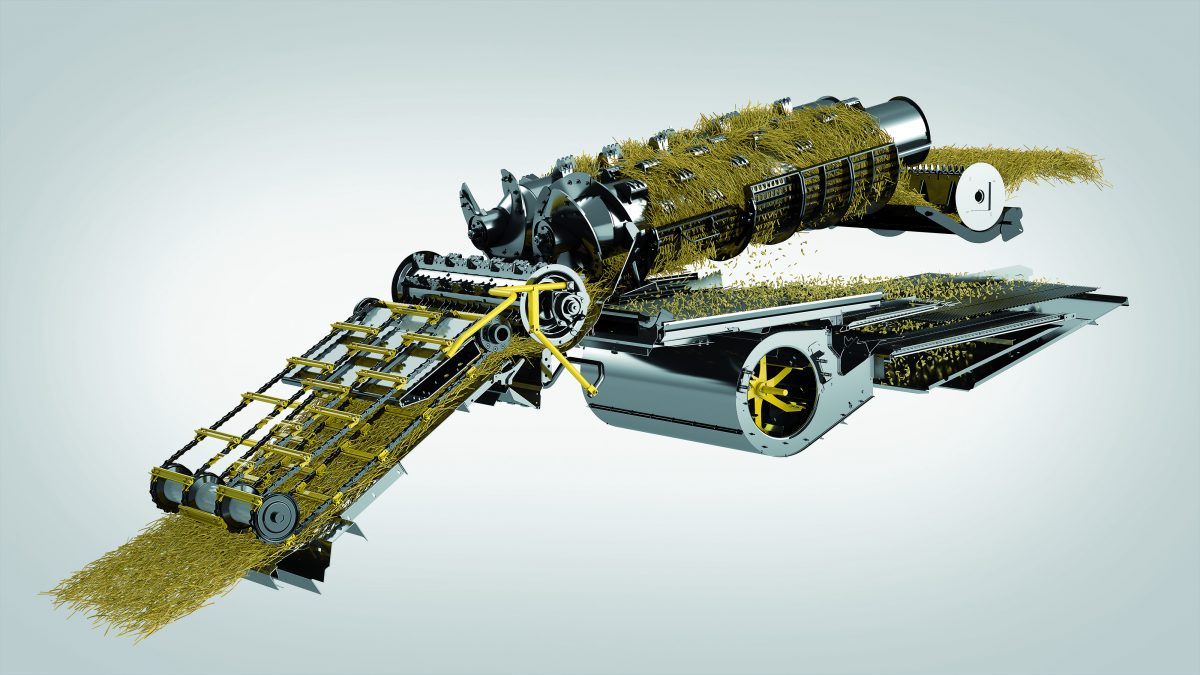

The Dynamic Feed Roll Reverser, which consists of a hydraulic cylinder, a ratchet system and a toothed wheel on the DFR shaft, unblocks the DFR by rocking the drum. When a blockage occurs and the drum speed drops below 100 rpm, the combine’s threshing and feeding functions automatically disengage. The operator just needs to stop the combine and engage the reversing procedure using the IntelliView screen. The feeder reverses to empty the full length of the feeder chain; the hydraulic cylinder and ratchet system reverse the DFR drum.

When the crop is cleared and the hydraulic circuit doesn’t meet resistance, the reversing procedure is completed. The feeder reverses again to empty the full length of the feeder chain. When this is completed, the operator can re-engage the rotors and feeder to resume combining. The entire operation to clear the blockage only takes around 10 minutes.

New Holland Agriculture’s reputation is built on the success of our customers, cash crop producers, livestock farmers, contractors, vineyards, or groundscare professionals. They can count on the widest offering of innovative products and services: a full line of equipment, from tractors to harvesting, material handling equipment, complemented by tailored financial services from a specialist in agriculture.

A highly professional global dealer network and New Holland’s commitment to excellence guarantees the ultimate customer experience for every customer. For more information on New Holland visit www.newholland.com