WJ Group Champions Road Safety with Emergency Area Retrofit on M6 Motorway

When it comes to road safety, every second counts. Recognising the need for safer and more efficient emergency areas, WJ Group has stepped up to the plate, playing a pivotal role in National Highways’ National Emergency Area Retrofit programme.

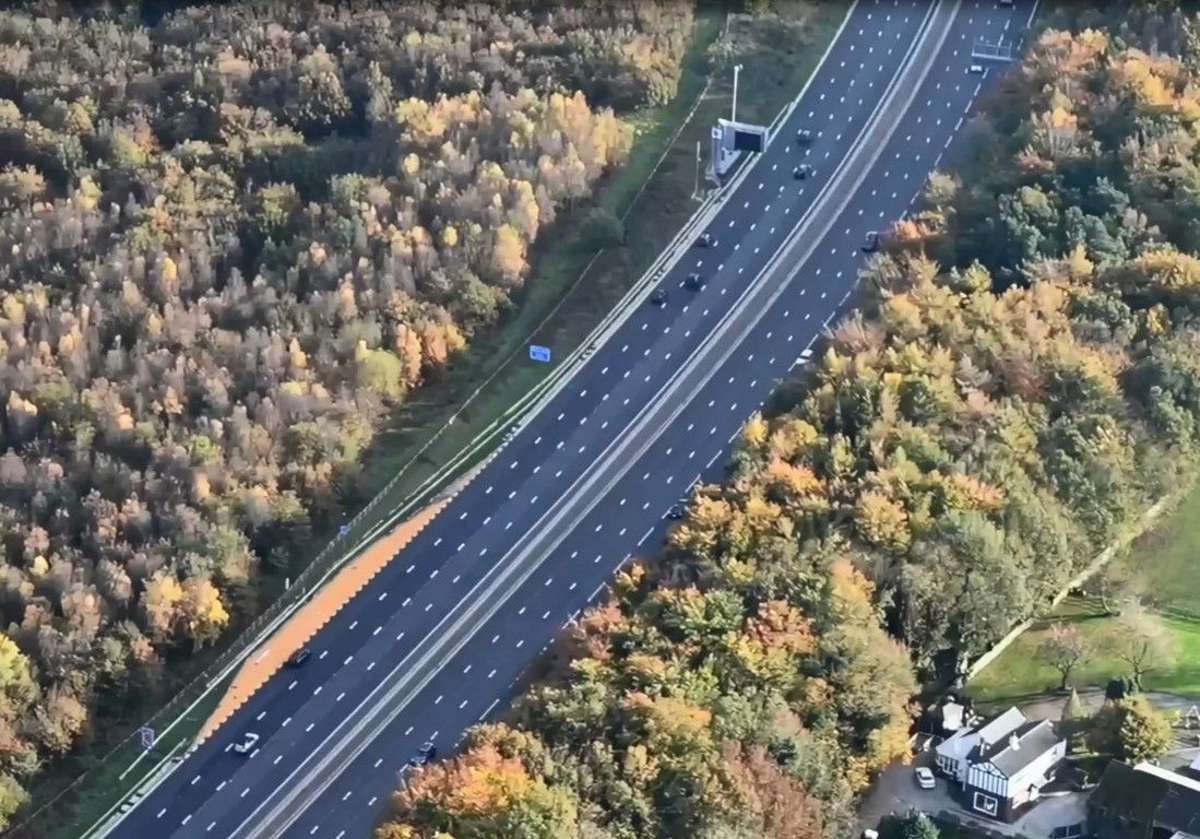

This ambitious initiative aims to bolster road safety across the M6, one of the UK’s busiest motorways, by introducing innovative solutions that enhance functionality and reduce downtime.

A Nationwide Effort to Boost Motorway Safety

Slated for completion by March 2025, the National Emergency Area Retrofit programme is spearheaded by National Highways and delivered by the SMP Alliance. The plan? To add 150 new emergency areas across all lane running sections of the strategic road network.

These dedicated zones are designed to give motorists a safe haven during emergencies, from breakdowns to sudden health issues. Between junctions 21a and 26 of the M6 alone, 22 new emergency areas are being installed with the help of WJ Group and their state-of-the-art coloured surfacing product.

Addressing the Need for High Friction Surfacing

Key to the success of these emergency areas is ensuring they provide high levels of friction to prevent skidding and minimise stopping distances. These friction levels are critical for enabling vehicles to come to a safe halt, especially under emergency conditions.

However, traditional surfacing solutions often fall short, requiring extended installation times that increase costs, environmental impact, and risk to workers. Each area could previously take up to two days to complete, necessitating prolonged on-site presence of workers and vehicles. This inefficiency spurred the need for an innovative approach, and WJ Group delivered.

Revolutionising Emergency Area Surfacing

Enter RapidGrip, WJ Group’s ground-breaking surfacing solution. Developed in collaboration with SMP Alliance partners like Costain Group and WSP, RapidGrip combines pigment, aggregate, and binder into a single application process. This eliminates the need for multiple curing periods and additional equipment like sweeper trucks, slashing installation times and disruptions.

With RapidGrip, WJ Group achieved remarkable efficiency. Two emergency bays could be completed per shift using just one truck, enabling all 22 bays to be retrofitted across 14 shifts. What’s more, the solution achieved an impressive average of 78 pendulum test value (PTV), ensuring optimal friction levels for motorist safety.

Martin Webb, Innovation Director at WJ Group, highlighted the importance of this achievement: “When drivers find themselves in the position where they need to pull over on the motorway, they require a safe and dedicated space to do so. With our high-friction RapidGrip solution, National Highways is ensuring that drivers can come to a stop safely in the new emergency areas.”

A Win-Win for Safety, Sustainability, and Efficiency

RapidGrip isn’t just about speed; it’s also about sustainability and worker safety. By reducing the number of curing periods and equipment required, the solution minimises the environmental footprint of each installation. Additionally, fewer on-site hours mean reduced exposure of workers to road hazards, aligning with SMP Alliance’s commitment to greener, safer, and more efficient solutions.

Webb further emphasised: “Innovations such as RapidGrip mean that the installation and retrofit of these emergency areas can be carried out with minimal disruption to the public and ensure workers are not on the road for an extended period, while maximising the safety of road users.”

The Broader Impact on Road Safety

While the retrofit on the M6 is a notable milestone, it’s part of a larger strategy to enhance safety across the UK’s motorways. The integration of innovative technologies like RapidGrip sets a precedent for future infrastructure projects. By fostering collaboration between suppliers and delivery partners, the SMP Alliance is paving the way for smarter, more effective road safety solutions.

Moreover, this initiative underscores the importance of proactive maintenance and modernisation in adapting to the evolving needs of road users. With more vehicles on the road and increasing demand for safer infrastructure, solutions like those provided by WJ Group are indispensable.

A Safer Journey Ahead

The National Emergency Area Retrofit programme and WJ Group’s innovative contributions exemplify what can be achieved when safety, efficiency, and sustainability take centre stage.

As these new emergency areas become operational, motorists can rest assured that the roads are becoming safer, one innovative solution at a time.