Hexagon Robotics and Microsoft Building the Autonomous Factory Floor

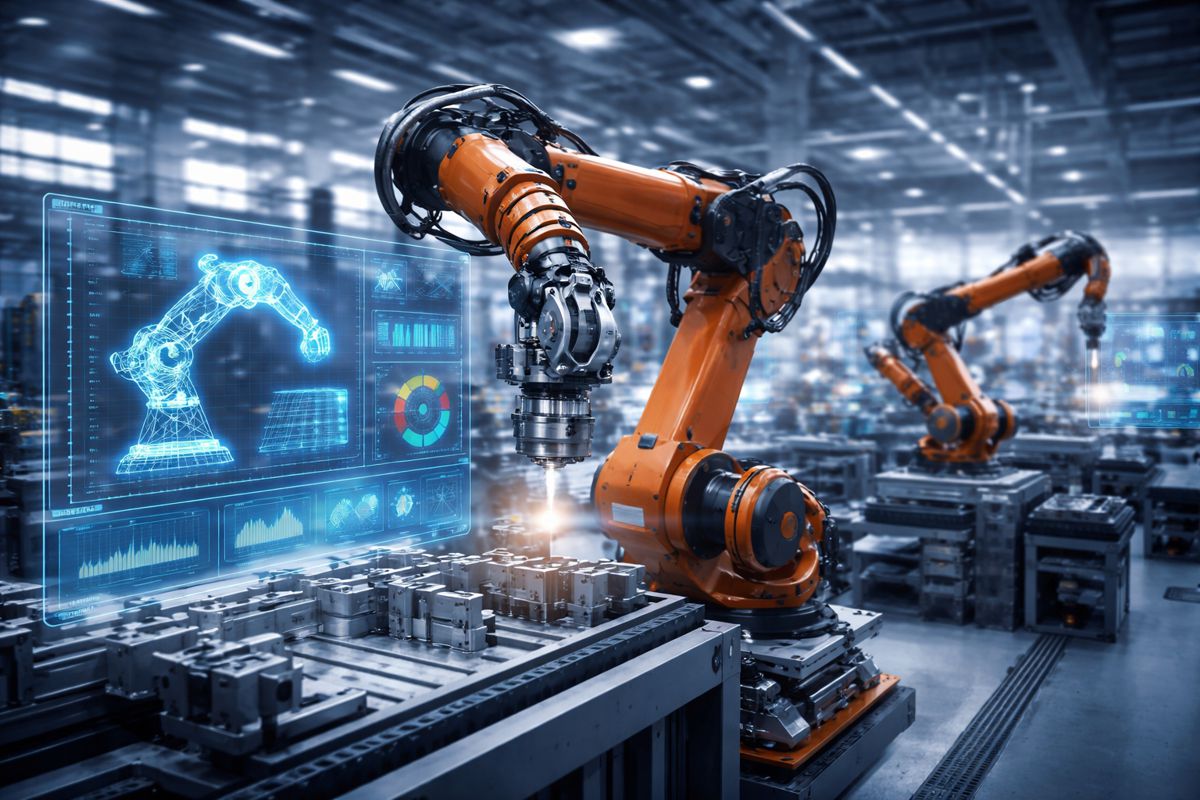

In a move that underscores the accelerating convergence of cloud computing, artificial intelligence and advanced robotics, Hexagon Robotics has entered into a strategic partnership with Microsoft to push humanoid robots closer to large-scale industrial deployment. The collaboration centres on data-driven, adaptive manufacturing and aims to translate years of research in Physical AI into production-ready systems that can operate safely and efficiently alongside human workers.

At its core, the partnership reflects a shared belief that the next wave of industrial automation will not be defined by isolated machines performing repetitive tasks. Instead, it will be shaped by intelligent, adaptable humanoid robots capable of learning from their environment, interpreting complex data streams, and responding to real-world variability on the factory floor. By aligning Hexagon Robotics’ strengths in sensor fusion, spatial intelligence and robotics with Microsoft’s cloud-scale AI infrastructure, the two companies are positioning themselves at the forefront of this shift.

A Strategic Alliance Built on Complementary Strengths

Hexagon Robotics brings to the table decades of experience in measurement technologies, industrial sensors and robotics. Its work in sensor fusion enables machines to combine data from multiple sources, such as vision systems, force sensors and spatial mapping tools, to form a coherent understanding of their surroundings. This capability is fundamental for humanoid robots expected to manipulate objects, navigate dynamic environments and perform inspection tasks with high precision.

Microsoft, meanwhile, contributes its extensive cloud and AI ecosystem. Platforms such as Azure provide the computational backbone required to train, deploy and scale complex AI models, while services including Fabric Real-Time Intelligence, Azure IoT Operations and Azure App Service enable real-time data processing and seamless integration between digital systems and physical assets. Together, these capabilities create a pipeline that runs from data acquisition on the shop floor through to actionable intelligence delivered at scale.

Scaling Physical AI From Concept to Reality

One of the partnership’s primary goals is the scaling of Physical AI frameworks across imitation learning, reinforcement learning and multimodal vision-language-action models. These approaches allow robots to learn tasks by observing human demonstrations, refining their behaviour through trial and error, and interpreting instructions that combine visual cues, language and contextual understanding.

In industrial settings, this matters because traditional programming methods struggle to cope with variability. Parts may be positioned slightly differently, lighting conditions may change, and workflows often evolve. By leveraging one-shot imitation learning and multimodal training, humanoid robots can adapt more quickly, reducing downtime and the need for extensive reprogramming. The collaboration seeks to overcome long-standing challenges in data management and model training that have slowed adoption to date.

From Cloud to Factory Floor

A defining feature of the alliance is its emphasis on joint customer engagement. Rather than limiting the collaboration to research and development, Hexagon Robotics and Microsoft plan to work directly with customers to deploy AI-driven robotics powered by Azure, taking automation from concept through to operational reality.

This approach acknowledges that industrial adoption depends as much on integration and reliability as on technical capability. Manufacturers need solutions that can be deployed within existing production lines, comply with safety standards, and deliver a clear return on investment. By combining cloud-native services with robotics expertise, the partners aim to shorten deployment cycles and de-risk implementation for end users.

Targeting High-Impact Industries

The initial focus of the partnership will be on automotive, aerospace, manufacturing and logistics. These sectors face mounting pressure from labour shortages, rising quality expectations and the need for greater operational flexibility. Humanoid robots, designed to operate in environments built for humans, offer a compelling alternative to fixed automation systems.

In automotive and aerospace manufacturing, for example, humanoid robots can assist with manipulation and inspection tasks that require dexterity and situational awareness. In logistics, they can support material handling and quality checks across complex warehouse environments. By targeting these use cases first, the partnership aims to demonstrate tangible benefits where the business case for automation is already strong.

AEON and the Promise of Industrial Humanoids

Central to the collaboration is Hexagon’s industrial humanoid robot, AEON. Designed with advanced sensor fusion and spatial intelligence, AEON has already demonstrated real-time defect detection and operational intelligence in industrial scenarios. These capabilities highlight how humanoid robots can move beyond simple task execution to become active participants in quality assurance and process optimisation.

The integration of AEON with Microsoft’s cloud infrastructure enables continuous learning and improvement. Data collected during operations can be analysed in real time, feeding back into AI models that refine performance and adapt to new conditions. This closed-loop approach is essential for scaling humanoid robotics across multiple sites and use cases.

Addressing Labour Shortages and Workforce Evolution

Labour availability has emerged as a critical constraint across many industrial sectors. Ageing workforces, skills gaps and competition for talent are prompting manufacturers to rethink how work is organised. The Hexagon and Microsoft partnership explicitly positions humanoid robots as a response to these challenges, not as a replacement for human workers but as a means of augmenting them.

By keeping humans in the loop, humanoid robots can take on physically demanding, repetitive or hazardous tasks while enabling skilled workers to focus on supervision, problem-solving and continuous improvement. This vision aligns with broader industry trends that emphasise human-centric automation and the responsible use of AI.

Executive Perspectives on the Collaboration

Arnaud Robert, President of Hexagon Robotics, framed the partnership as a milestone in the company’s long-term strategy: “The strategic partnership with Microsoft is a big step towards realising our vision to build an autonomous future and address labour shortage across vital industries. We are excited to collaborate with Microsoft to advance our Physical AI roadmap and deploy high-performing and adaptable humanoid solutions for our customers”.

From Microsoft’s perspective, the collaboration represents an opportunity to bridge innovation and practical impact. Aaron Schnieder, Vice President of Engineering and Emerging Technologies at Microsoft, noted: “This partnership with Hexagon Robotics marks a pivotal moment in bridging the gap between cutting-edge humanoid robot innovation and real-world industrial impact. By combining AEON’s sensor fusion and spatial intelligence with Microsoft Azure’s scalable AI and cloud infrastructure, we’re empowering customers to deploy adaptive, AI-powered humanoid robots that advance autonomous manufacturing from the factory floor to the global supply chain”.

Overcoming Deployment Challenges

Despite rapid advances in robotics and AI, deploying humanoid robots at scale remains complex. Data management, model training and system integration can become bottlenecks, particularly when dealing with multimodal inputs and real-time decision-making. The partnership aims to tackle these issues head-on by leveraging cloud-native architectures and standardised platforms.

Microsoft Fabric’s real-time intelligence capabilities, combined with Azure IoT Operations, allow for continuous monitoring and optimisation of robotic systems. This infrastructure supports not only performance improvements but also traceability and compliance, which are critical in regulated industries such as aerospace and automotive manufacturing.

A Broader Vision for Autonomous Industry

Beyond immediate applications, the collaboration points towards a broader transformation in how industrial systems are designed and operated. As humanoid robots become more capable and interconnected, they have the potential to act as mobile data hubs, feeding insights into enterprise systems and enabling more responsive supply chains.

For policymakers and industry leaders, this raises important questions around standards, safety and workforce development. Partnerships like the one between Hexagon Robotics and Microsoft illustrate how cross-industry collaboration can accelerate innovation while addressing practical constraints. By aligning technological ambition with real-world requirements, the two companies are contributing to a more resilient and adaptable industrial landscape.

A Commitment to Intelligent, Scalable and Autonomous Solutions

As the partnership progresses, its success will be measured not only by technical milestones but by adoption on the factory floor. Demonstrating reliable performance, clear productivity gains and positive workforce outcomes will be essential to building confidence in humanoid robotics as a mainstream industrial tool.

With a shared commitment to intelligent, scalable and autonomous solutions, Hexagon Robotics and Microsoft are setting out to redefine what is possible in modern manufacturing and logistics. Their collaboration signals a future where humanoid robots play an integral role in addressing labour challenges, enhancing efficiency and supporting the evolution of global industry.