AI and Digital Twins could lower Nuclear Energy Costs

Nuclear power plants provide large amounts of electricity without releasing planet-warming pollution. But the expense of running these plants has made it difficult for them to stay open. If nuclear is to play a role in the U.S. clean energy economy, costs must come down. Scientists at the U.S. Department of Energy’s (DOE) Argonne National Laboratory are devising systems that could make nuclear energy more competitive using artificial intelligence.

Nuclear power plants are expensive in part because they demand constant monitoring and maintenance to ensure consistent power flow and safety. Argonne is midway through a $1 million, three-year project to explore how smart, computerized systems could change the economics.

“Operation and maintenance costs are quite relevant for nuclear units, which currently require large site crews and extensive upkeep,” said Roberto Ponciroli, a principal nuclear engineer at Argonne. “We think that autonomous operation can help to improve their profitability and also benefit the deployment of advanced reactor concepts.”

The project, funded by the DOE Office of Nuclear Energy’s Nuclear Energy Enabling Technologies program, aims to create a computer architecture that could detect problems early and recommend appropriate actions to human operators. The technology could save the nuclear industry more than $500 million a year, Ponciroli and colleagues estimate.

A typical nuclear plant can hold hundreds of sensors, all of them monitoring different parts to make sure they are working properly.

“In a world where decisions are made according to data, it’s important to know that you can trust your data,” Ponciroli said. “Sensors, like any other component, can degrade. Knowing that your sensors are functioning is crucial.”

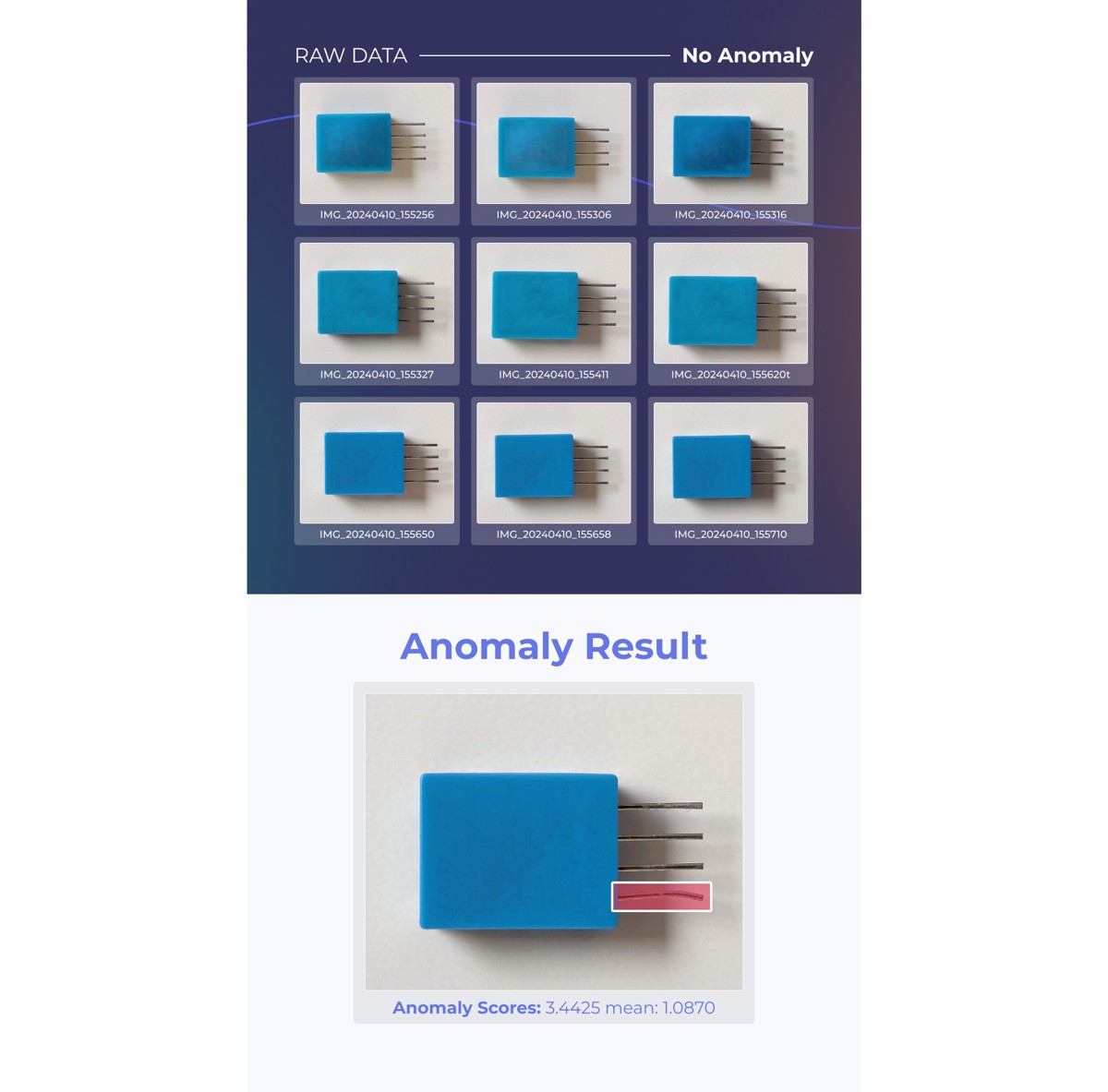

The job of inspecting each sensor — and also the performance of system components such as valves, pumps, heat exchangers — currently rests with staff who walk the plant floor. Instead, algorithms could verify data by learning how a normal sensor functions and looking for anomalies.

Having validated a plant’s sensors, an artificial intelligence system would then interpret signals from them and recommend specific actions.

Ponciroli offers an example: Let’s say your car’s dashboard alerts you to a tire with low air pressure. You know that you don’t need to pull over right away, but you might decide to slow down a bit to avoid a puncture until you can fill the tire with air.

Humans make these types of judgment calls all the time. We evaluate information, make a decision and take action, like altering controls (in the scenario above, slowing down the car) and making repairs. An artificial intelligence method called reinforcement learning replicates the brain’s logic by teaching the system to make decisions by evaluating potential outcomes. At a nuclear plant, computers could detect problems and flag them to plant operators as early as possible, helping optimize controls and also avert more expensive repairs down the line. At the same time, computers could prevent unnecessary maintenance on equipment that doesn’t need it.

“The lower-level tasks that people do now can be handed off to algorithms,” said Richard Vilim, an Argonne senior nuclear engineer. “We’re trying to elevate humans to a higher degree of situational awareness so that they are observers making decisions.”

Partnering with industry to develop testing scenarios, Argonne engineers have built a computer simulation, or “digital twin,” of an advanced nuclear reactor. While the system is designed to serve new reactor technologies, Vilim said, it’s also flexible enough to be applied at existing nuclear plants.

The team is validating its artificial intelligence concept on the simulated reactor, and so far they have completed systems to control and diagnose its virtual parts. The remainder of the project will focus on the system’s decision-making ability — what it does with the diagnostic data.

Because an autonomous nuclear plant requires these varied functions, the end product of the Argonne team’s work is a system architecture that stitches multiple algorithms together. For example, engineers are adapting code including Argonne’s System Analysis Module (SAM), an analysis tool for advanced reactors. SAM, which was developed in collaboration with engineering firm Kairos Power, won a 2019 R&D 100 award.

“Argonne is well suited to this project, because we already have all the capabilities we need in-house,” Ponciroli said. “It’s just a matter of combining them to get even more out of them.”