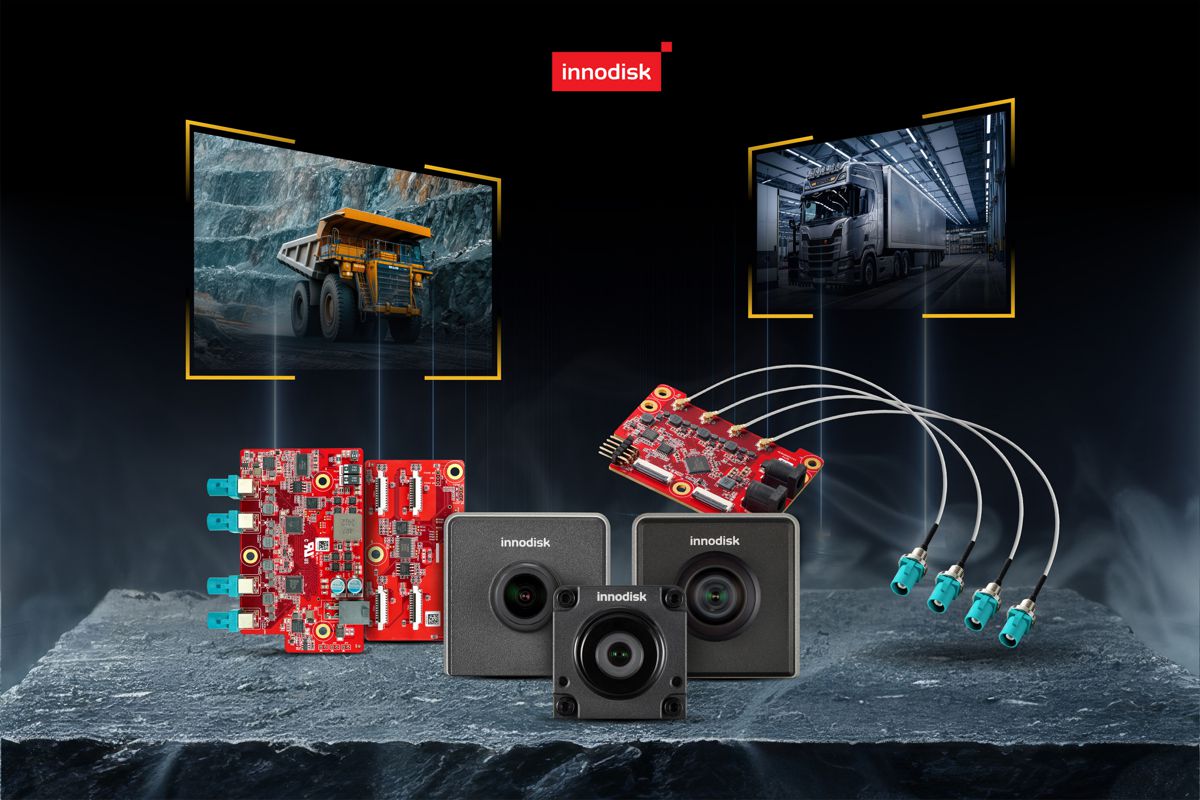

Innodisk Camera Module Delivers Edge Vision for Autonomous Systems

Innodisk has unveiled an innovative GMSL2 camera module and adapter board series that delivers long‑distance, low‑latency image transmission designed for demanding edge AI environments. The new series offers streamlined integration for mobility systems, heavy industrial vehicles, outdoor robotics, and advanced surveillance. These improvements support real‑time analytics, multi‑sensor perception, and accurate decision‑making within increasingly automated industrial ecosystems.

The solution enables stable video delivery over extended ranges, supporting real‑world conditions where vehicles, machinery, or robotic platforms may be dispersed across broad work environments. As industries adopt fully autonomous workflows, reliable edge‑based vision is becoming indispensable for intelligent navigation, safety systems, and asset monitoring.

Enhanced Range, Resolution, and Lighting Control

The Innodisk GMSL2 camera module supports transmission distances of up to 15 metres over a FAKRA cable while maintaining high‑quality 13‑megapixel imaging performance. At the core of the module is the Sony ISX031 image sensor featuring an integrated image signal processor, High Dynamic Range capability, and LED flicker mitigation.

The HDR performance delivers consistent brightness handling and stable image clarity in challenging environments that frequently alternate between very bright and low‑light conditions. Work taking place under intense artificial lighting, rapidly changing outdoor environments, or deep interior tunnels benefit from the camera’s ability to adjust dynamically without losing vital visual data.

The LED flicker mitigation technology is particularly valuable for applications involving pulsed LED lighting or fast‑moving vehicles where light sources are not captured evenly. This eliminates unstable visual artefacts that compromise computer‑vision accuracy, which results in safer and more reliable perception even at higher speeds.

Engineered for Harsh Industrial Conditions

The module is designed using a ruggedised IP67 and IP69K enclosure, enabling it to withstand heavy vibration, pressurised water contact, dust ingress, and extreme weather. This durability is suited for high‑impact applications such as port machinery, mining operations, large construction vehicles, logistics machinery, and outdoor robotic fleets.

Modern industrial environments depend on uninterrupted visual operation for autonomous movement, remote supervision, anti‑collision systems, and on‑equipment diagnostics. By eliminating the vulnerability of conventional cameras, Innodisk provides a dependable platform for safety‑critical infrastructure where equipment operates in remote and unpredictable conditions.

Integrated NVIDIA Jetson Orin Connectivity for Faster Deployment

To accelerate development cycles, Innodisk provides flexible adapter board solutions fully optimised for NVIDIA Jetson Orin AI computing platforms. These customisable boards reduce integration challenges and provide a faster pathway from prototype to deployment, particularly for OEMs, fleet automation companies, or robotics manufacturers.

The system supports multi‑camera connectivity and synchronous streaming, allowing simultaneous viewpoints or sensor fusion without latency issues. This capability supports multi‑angle perception and enhances AI accuracy by combining several cameras or different sensor types.

Users gain rapid validation during system development and can scale complex edge‑vision applications without lengthy software reconfiguration. This creates advantages across autonomous mining trucks, warehouse logistics platforms, last‑mile delivery robots, and industrial surveillance systems.

Multi‑Sensor Collaboration for Advanced Autonomy

Innodisk is expanding its partnerships to further enhance interoperability and cross‑platform intelligence. These collaborations include heavy‑duty vehicle applications with Advantech, a major provider of rugged computing solutions.

Van Lin, Senior Director of Advantech’s iMobile Solutions and Rugged Edge AI Division, commented: “Innodisk’s GMSL2 cameras, combined with Advantech’s TREK/REX rugged in‑vehicle edge computing solutions, leverage sensor fusion technology to integrate LiDAR, radar, and other diverse sensors. This enables comprehensive environmental sensing, significantly enhancing the reliability of AI vision for autonomous operations while driving greater safety and efficiency of intelligent and autonomous industrial vehicles.”

These combined platforms allow edge‑vision systems to integrate multiple data layers from radar, LiDAR, optical cameras, and additional industrial sensing mechanisms. Autonomous machinery can evaluate movement, proximity, and spatial conditions with far greater accuracy, reducing operational hazards and improving fleet efficiency.

Expanding Edge‑Vision Ecosystems Through Partnerships

The GMSL2 product line is deployed alongside Innodisk’s subsidiary Aetina, which provides heterogeneous edge‑AI computing solutions. Aetina contributes to broad visual sensing and advanced analytics across edge robotics, surveillance, and industrial computing.

Innodisk and Aetina work with several global partners, including Advantech, ASUS, and ASRock Industrial, to scale the availability of GMSL2 camera modules across multiple AI and embedded computing environments. Their combined deployments cover industrial controllers, robotic automation systems, in‑vehicle platforms, and advanced AI acceleration hardware.

Together, these partnerships improve adoption speed and expand market reach across mining operations, smart manufacturing, intelligent logistics, and outdoor fleet automation.

Supporting the Future of Autonomous Industry

As industries transition towards autonomous mobility, the importance of long‑range, low‑latency edge‑vision systems will continue to grow. The Innodisk GMSL2 series demonstrates how sensing reliability, environmental resilience, and real‑time AI processing can allow heavy machinery and robotic platforms to operate more safely and efficiently.

High‑confidence perception is becoming a strategic requirement in mines, ports, automated warehouses, tunnel construction, and other complex operational landscapes. By addressing sensor interoperability, edge‑based processing, and harsh‑environment reliability, the system enables greater scalability and a more intelligent industrial infrastructure.

Innodisk and its partners are advancing the direction of rugged AI‑driven vision, which is moving increasingly closer to full automation, remote fleet coordination, and predictive supervision. Emerging applications will continue to evolve as more sectors adopt integrated sensor fusion and real‑time machine perception to minimise operational risk and improve sustainability.