3D Printed Sand gets super strength with Polymer discovery

Researchers at the Department of Energy’s Oak Ridge National Laboratory designed a novel polymer to bind and strengthen silica sand for binder jet additive manufacturing, a 3D-printing method used by industries for prototyping and part production.

The printable polymer enables sand structures with intricate geometries and exceptional strength – and is also water soluble.

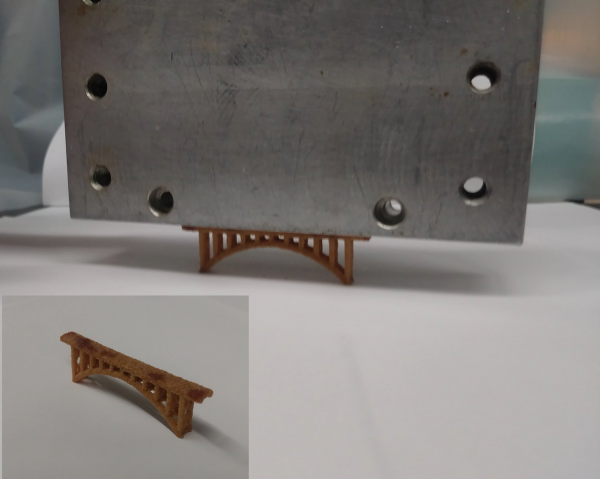

The study, published in Nature Communications, demonstrates a 3D-printed sand bridge that at 6.5 centimetres can hold 300 times its own weight, a feat analogous to 12 Empire State Buildings sitting on the Brooklyn Bridge.

The binder jet printing process is cheaper and faster than other 3D-printing methods used by industry and makes it possible to create 3D structures from a variety of powdered materials, offering advantages in cost and scalability. The concept stems from inkjet printing, but instead of using ink, the printer head jets out a liquid polymer to bind a powdered material, such as sand, building up a 3D design layer by layer. The binding polymer is what gives the printed sand its strength.

The team used polymer expertise to tailor a polyethyleneimine, or PEI, binder that doubled the strength of sand parts compared with conventional binders.

Parts printed via binder jetting are initially porous when removed from the print bed. They can be strengthened by infiltrating the design with an additional super-glue material called cyanoacrylate that fills in the gaps. This second step provided an eight-fold strength increase on top of the first step, making a polymer sand composite stronger than any other and any known building materials, including masonry.

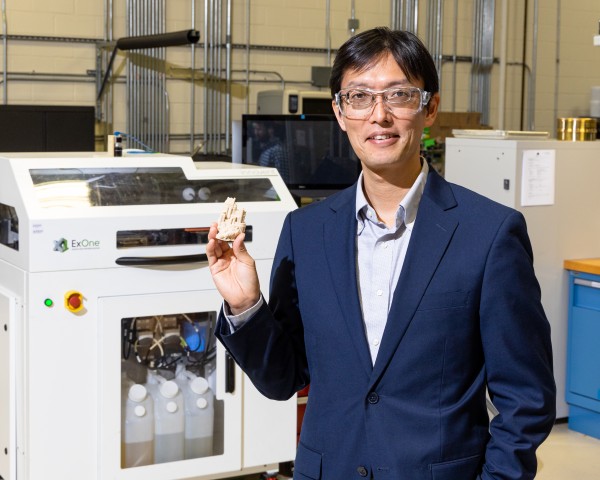

“Few polymers are suited to serve as a binder for this application. We were looking for specific properties, such as solubility, that would give us the best result. Our key finding was in the unique molecular structure of our PEI binder that makes it reactive with cyanoacrylate to achieve exceptional strength,” said ORNL’s Tomonori Saito, a lead researcher on the project.

Parts formed with conventional binders are made denser with infiltrate materials, such as super glue, but none have reached close to the performance of the PEI binder. The PEI binder’s impressive strength stems from the way the polymer reacts to bond with cyanoacrylate during curing.

Silica sand is a cheap, readily available material that has been gaining interest in automotive and aerospace sectors for creating composite parts. Lightweight materials, such as carbon fiber or fiberglass, are wrapped around 3D-printed sand cores, or “tools,” and cured with heat. Silica sand is attractive for tooling because it does not change dimensions when heated and because it offers a unique advantage in washable tooling. In composite applications, using a water-soluble binder to form sand tools is significant because it enables a simple washout step with tap water to remove the sand, leaving a hollow composite form.

“To ensure accuracy in tooling parts, you need a material that does not change shape during the process, which is why silica sand has been promising. The challenge has been to overcome structural weakness in sand parts,” said Dustin Gilmer, a University of Tennessee Bredesen Center student and the study’s lead author.

Current sand casting moulds and cores have limited industrial use because commercial methods, such as washout tooling, apply heat and pressure that can cause sand parts to break or fail on the first try. Stronger sand parts are needed to support manufacturing at a large scale and enable rapid part production.

“Our high-strength polymer sand composite elevates the complexity of parts that can be made with binder jetting methods, enabling more intricate geometries, and widens applications for manufacturing, tooling, and construction,” said Gilmer.

UT-Battelle manages ORNL for the Department of Energy’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. The Office of Science is working to address some of the most pressing challenges of our time.