Pavement Milling

Also called cold planing or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to create a smooth pavement or full-depth removal of the road surface and courses underneath.

Recycling

This is the greatest benefit from milling a road, and widely used for pavement rehabilitation throughout the world. The milled pavement materials are removed from the site, put through a crusher, and recycled for use as aggregate for the new pavement.

Reclaimed Asphalt Pavement (RAP)

Has substantial financial benefit savings, not only on the costs associated with quarrying and transporting new aggregates, but also in time as pavement milling is a fast process that leaves a level base behind.

Pavement Milling Operations

- Removing distresses from the surface to leave a level and smooth surface

- Removing aggregate that has become separated from the binder course (Ravelling)

- Removing sections where the bitumen has come to the surface of the road (Bleeding)

- Removing low spots or wheel tracking in the road (Rutting)

- Removing washboard like effects formed along the road width (Shoving)

- Removing uneven road surface defects such as swells, bumps, or depressions

- Removing damage caused by vehicle accidents, fires or chemical spills

- Removing existing material to allow road structures for proper installation These include kerbs, reveals, manholes and guardrails / barriers

- Removing existing material under structures such as bridges where height must be maintained.

- Grading the roadway to create the required camber or gradient to maintain proper drainage of the roadway

- Forming speed tables and rumble strips used to slow traffic

Definitions

The Asphalt Recycling and Reclaiming Association (ARRA) has created the following standard definitions for cold milling recognised by the US Federal Highway Administration:

- Class I Milling to remove surface irregularities

- Class II Milling to uniform depth as shown on plans and specifications

- Class III As class II with the addition of cross slope

- Class IV Milling to the base or subgrade (full depth)

- Class V Milling to different depths at different locations

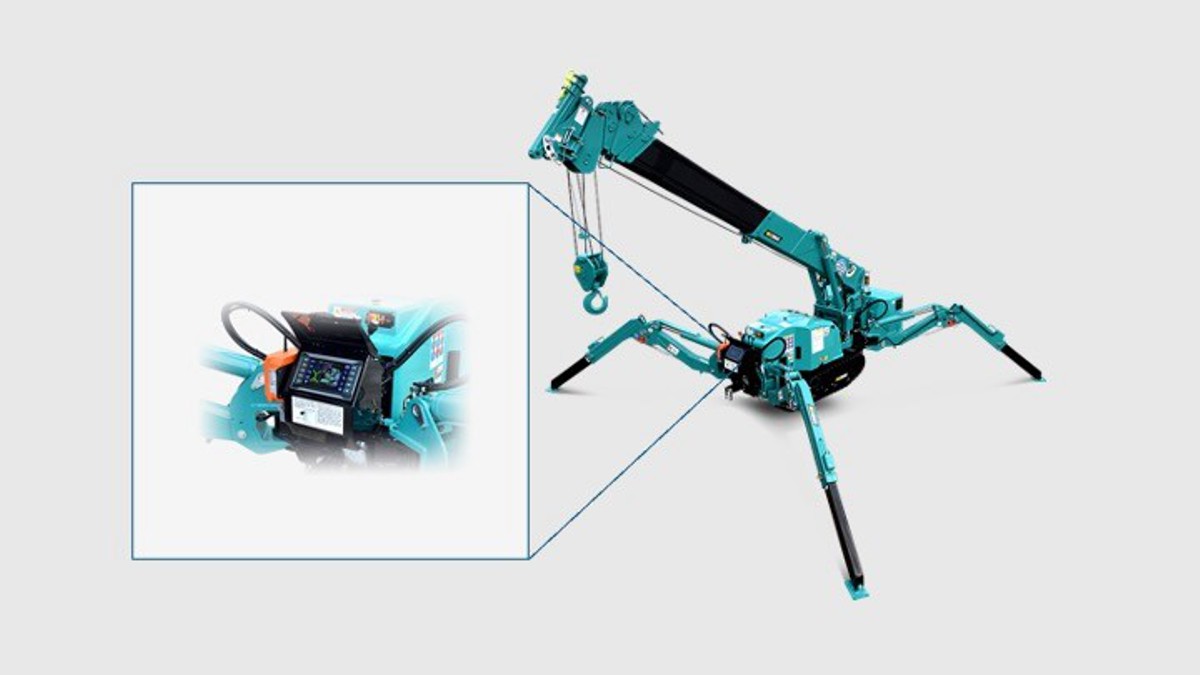

Asphalt Milling Machines

Large milling machines or cold planers have a large rotating cutting drum used to grind into and remove the existing asphalt pavement.

The cutting drum has removable carbide teeth that spiral in from the edges to push the loosened material to the centre and taken away by a conveyor belt into a waiting truck. The teeth are replaced as they wear out which can be hours or days depending on the abrasiveness of the aggregate in the existing pavement. Road furniture such as iron manholes can damage the teeth.

The spacing of the teeth around the drum determines the finish of the milled surface with micro-milling drums giving the best finish with much tighter spacing.

Modern milling equipment use state of the art computers and sensors such as lasers to control depth, slope, and the profile of the milled surface to an accuracy of +/- 5 mm or less.