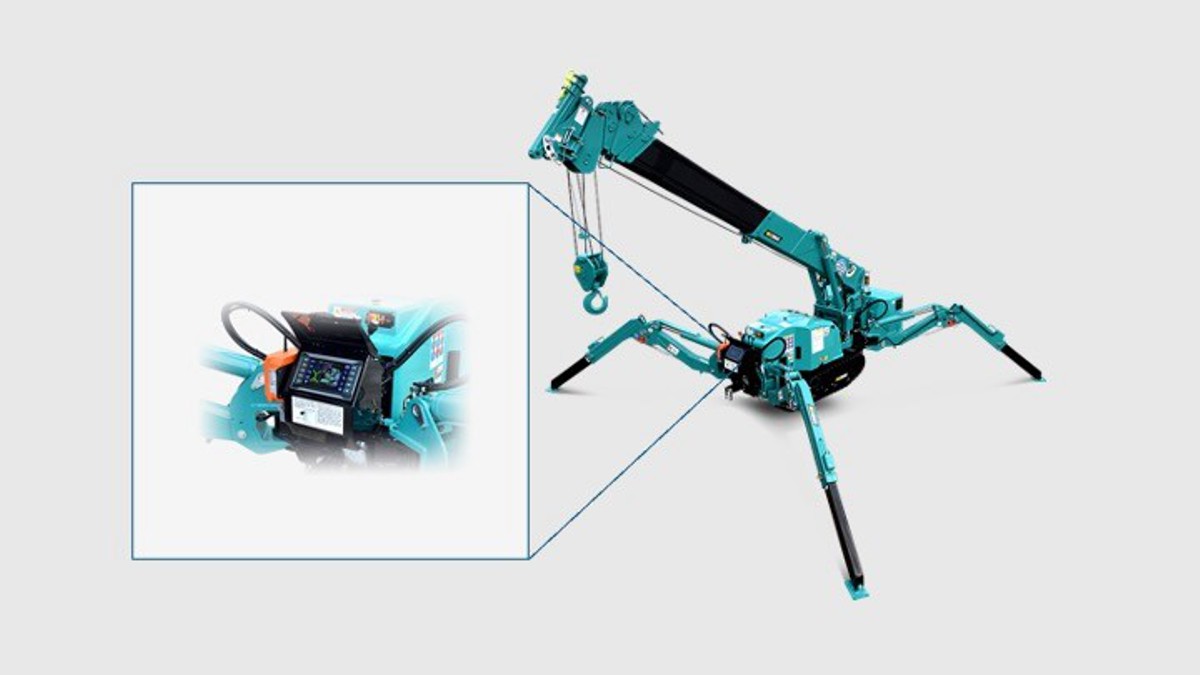

Roadtec compact milling machines – manoeuvrable, flexible and versatile

Some projects have small, tight spaces that require compact equipment with maneuverability. In these cases, contractors employ small dozers, mini-excavators, and compact track loaders. Add to that mix a small milling machine specifically suited for removing road pavements, milling pavement strips, or milling tie-ins.

The Roadtec RX-100e is designed to be a highly manoeuvrable small-size mill with a base cutting width of 20-inches (508 mm), maximum cutting depth of 8-inches (203 mm) deep, and a drum diameter with teeth of 30-inches (750 mm).

“Our customers have been telling us that the weight, balance, and power of the RX-100e make it ideal for cutting trenches, demarcation and precise manoeuvring, such as milling around manholes, or for other narrow spaces,” said Kyle Hammon, product manager for Roadtec, Inc., Chattanooga, TN. “It is a highly versatile machine that is capable of reaching spots that larger machines can’t get to.”

The compact machine features a shipping weight of 15,840-pounds (7,184 kg), a length of 12-feet, 8-inches (3.87 m), and a width 4-feet, 8-inches (1.42 m). The RX-100e milling machine is equipped with a hydraulically driven drum to provide, as the manufacturer states, high performance and reduced maintenance. Large service doors on both sides of the machine are for maintenance access to the interior components.

A Cummins QSB 4.5 Tier 4i compliant diesel engine powers the small utility cold planer. The machine’s 140 horsepower (103 kW) engine is cooled by a high-efficiency variable speed fan. The speed of the fan is based on cooling demand, which is designed to decrease the engine load and increase the fuel economy of the machine.

To add functional versatility, the right, rear leg tube on the cold planer is positioned alongside the cutter housing for normal milling, but the leg tube can also be rotated to a position in front of the cutter housing for flush-cut operations.

The operator station includes simple controls and an operator seat with comfort suspension that can slide out to the right of the machine to improve visibility.

“The RX-100e utility milling machine is proving to be the ideal choice for congested urban areas and other confined work sites,” Hammon states. “And like all other Roadtec machines, the RX-100e has an extremely strong frame completely fabricated, welded and assembled by us in Chattanooga.”

Article by Jeff Winke.