Ammann Mini Paver proves a popular choice

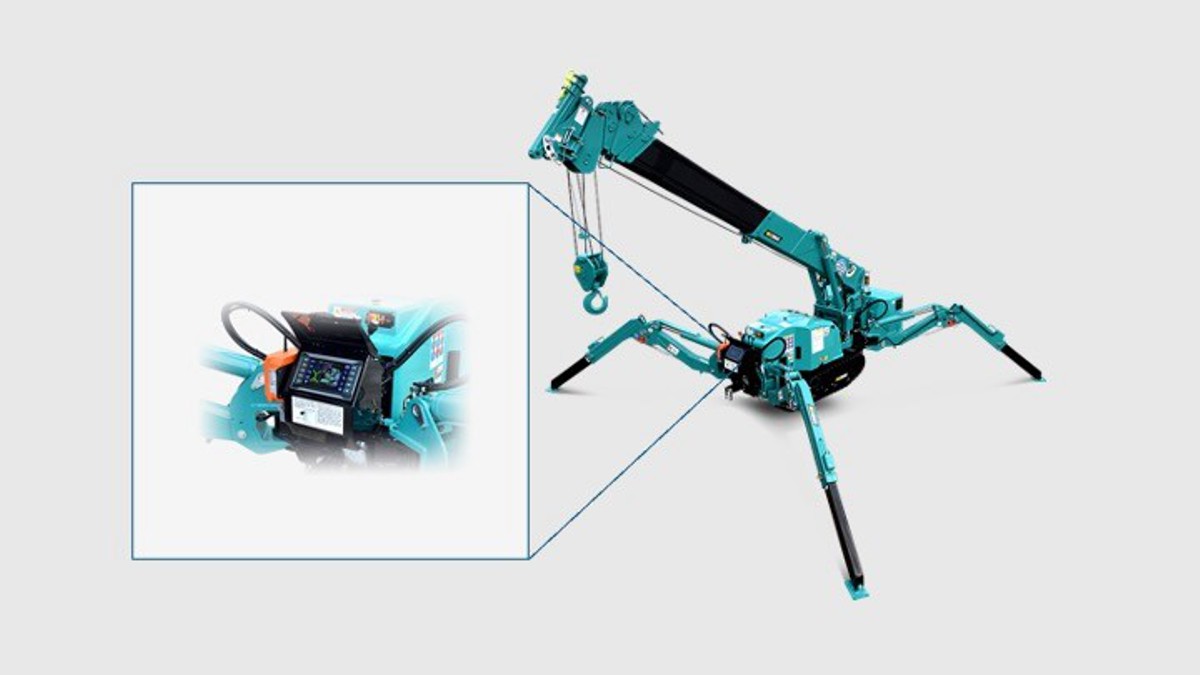

Customer reviews of the new Ammann mini paver continue to be positive, with contractors reporting the machines are ideal for small paving applications.

“The AFW 150-2 always draws a lot of attention when it shows up on jobsites or tradeshows,” said Marcus Utterodt, Global Commercial Manager Pavers. And this continues with the first machines being sold to customers. “Now we are seeing the next step: enthusiastic feedback from customers in the field.”

Separating the paver from the competition is its range of working widths – from 250 mm to 1650 mm. The narrowest widths are possible because material flow can be limited to half of the machine with a unique material flow divider system.

“Without the AFW 150-2, contractors working at those widths would have to place the material by hand, risking quality issues in terms of unevenness or bad pre-compaction,” Utterodt said.

Contractors have given the mini paver glowing reviews – and it’s easy to see why, Utterodt said. “We worked together with customers and took their feedback into consideration when developing this paver,” he said.

That input drove key features, including an improved dashboard, a new steering wheel and a hydraulic screed extension. The improved material flow system includes the capability to limit paving to a single side of the machine.

The paver maintains the unique machine concept of its predecessors that made it so successful in the field. It is a 3-wheel paver: 2 in the rear to enable traction and 1 in the front for steering. The fixed hopper can be side-loaded by a skid steer. Its tight turning radius enables performance in close spaces and when working with sharp curves.

“We kept features that made this mini paver unique, and then added some significant improvements when developing the AFW 150-2,” Utterodt said. “It’s very encouraging to see that the changes are having a real impact on the jobsite. Contractors continue to give the machine very positive reviews.”