Caterpillar introduces updates to their PM310, PM312 and Pm313 Cold Planers

Caterpillar Inc. announces new updates to the PM310, PM312 and PM313 Cold Planers.

The PM300 Series is ideal for small-to-medium job sites where compact dimensions, optimum maneuverability and high production capabilities are required. Wheel or track undercarriage designs are available for each model.

More Power

The Cat® C9.3 engine is now available with 249 kW (334 hp) of power, a 3% increase. Along with additional power, these machines also meet U.S. EPA Tier 4 Final and EU Stage V emission standards.

Improved Visibility and Ergonomics

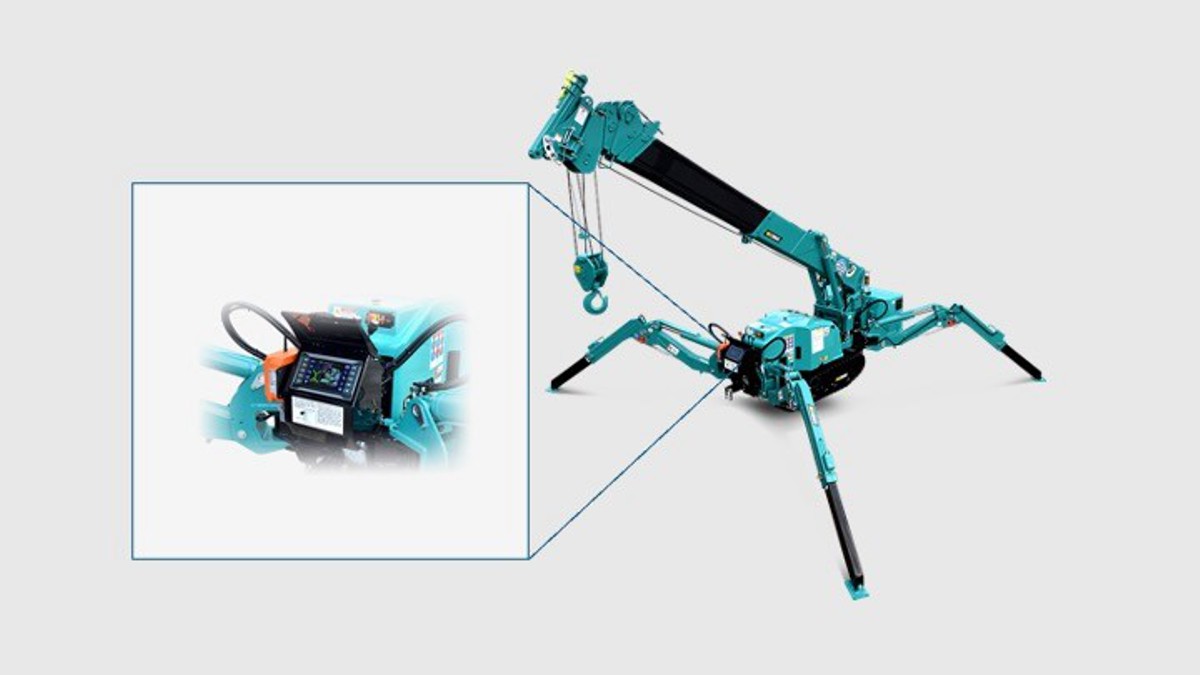

The Cat PM300 Series machines have improved visibility features with a sliding operator’s station, optional camera, and an auxiliary power connector for additional lighting. The new sliding station extends beyond the machine frame, approximately 215 mm (8.5 in.), providing operators with optimal visibility and line of site when following an edge.

These machines can be also equipped with an optional camera that mounts above the cutter box to improve visibility. The camera can be viewed through an LCD Display at the operator’s station enabling the operator to make closer cuts next to obstacles. With the addition of the sliding station, an armrest has been added to the right side to improve comfort. An optional auxiliary power connector located near the back of the machine accepts nighttime balloon lighting additions.

Easier Service

Servicing the rotor is now easier with an integrated rotor turning system. The hydraulically operated turning device controls the position of the rotor with a 2-button pendant that simplifies bit removal and replacement.

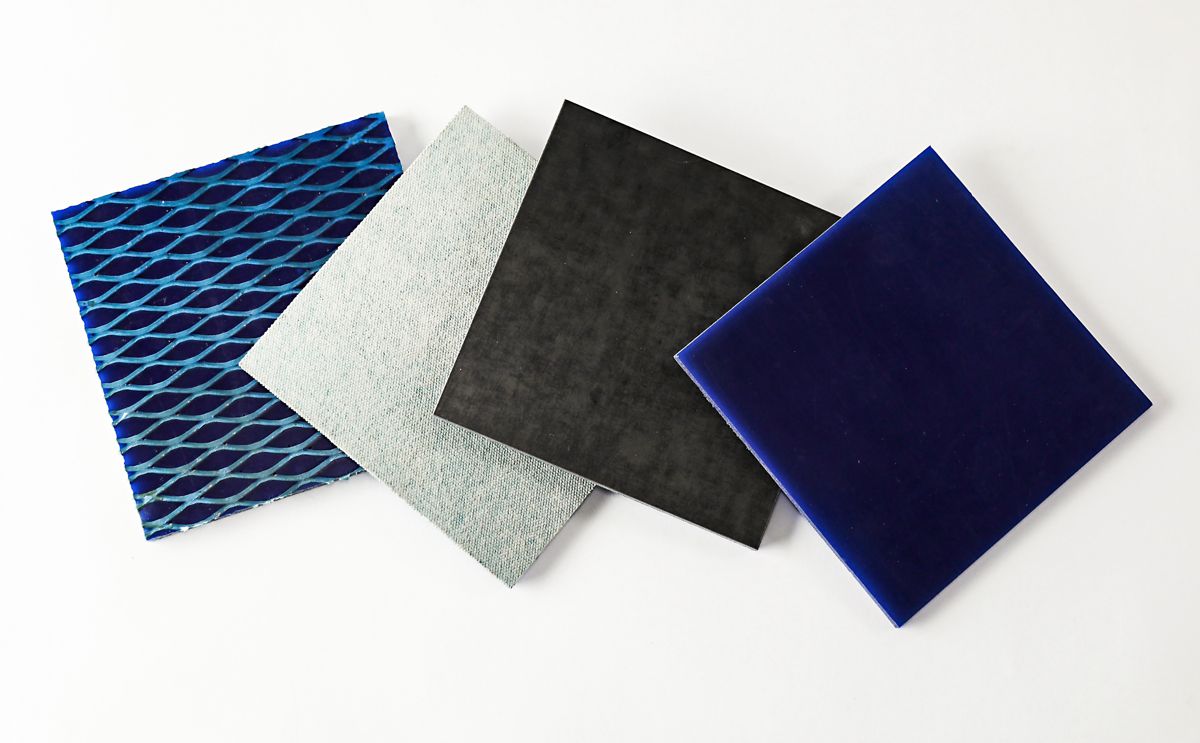

System K Rotors Optimized for Cat Cold Planers

Cat cold planers are available with the Cat System K milling rotors and feature efficient material flow with an excellent cutting pattern. Rotors are available with spacings of 8 mm, 15 mm and 18 mm for a wide range of milling applications. The dual taper retention design provides a reliable method for holding the tool holders in the blocks without the need for a retaining pin or bolt.

Reversible paddles and high strength alloys offer more resistance to abrasion and reduce wear for extended rotor life.

Optional Cat diamond bits feature a new design for the System K rotors and last up to 80 times longer than conventional carbide bits to extend intervals between bit maintenance, increase production and reduce operating costs. Cat Diamond Bits are sharper than conventional carbide bits, allowing the machine to cut faster and to reduce drag on the cutting system for better fuel economy in demanding applications.