Welsh Water uses Siltbuster wastewater treatment solution for Visitor Centre Refurb

Siltbuster Process Solutions, the water treatment specialist, has provided a temporary wastewater treatment solution for Welsh Water at its visitor centre in the Llys y Frȃn Country Park Reservoir, Pembrokeshire, whilst a brand-new works is built.

The visitor centre, which is currently being refurbished, will include a new outdoor activity zone, as well as a waterside cabin, which will support walkers, cyclists and water sports enthusiasts. The centre will also include staff offices and meeting rooms, plus a café, and cycle hire and repair facilities. A total of £4 million is being spent on the project, with £1.7m million of EU funding having been secured through the Welsh Government’s Tourism Attraction Development Programme.

The original wastewater treatment works, located onsite, would not have been capable of treating the increased amount of wastewater produced when the refurbished visitor centre reopened.

Young Bros (YB), the leading civil engineering contractor, is responsible for demolishing the works and constructing an enhanced capacity Rotating Biological Contractor (RBC) treatment works in its place. However, this can’t be built alongside the existing works, due to the lack of space, so YB tasked Siltbuster with providing a temporary solution to treat the waters generated onsite while the RBC system was under construction.

Jordan Jones, Project Manager at Young Bros, comments: “The great thing about Siltbuster Process Solutions’ work is that it means minimal wastewater has to be tankered offsite while the RBC is being built. Tankering can be really expensive, and Siltbuster Process Solutions’ solution has ensured that unplanned costs associated with tankering waste flows have been avoided. As well as that, with the daily lorry movements to and from site that would have been required, we would have risked upsetting locals, which nobody wants. Plus, when it comes down to it, Siltbuster Process Solutions’ temporary solution is simply more reliable than tankering for avoiding pollution events– after all, wastewater can still collect and overflow if you’re purely relying on tankering.”

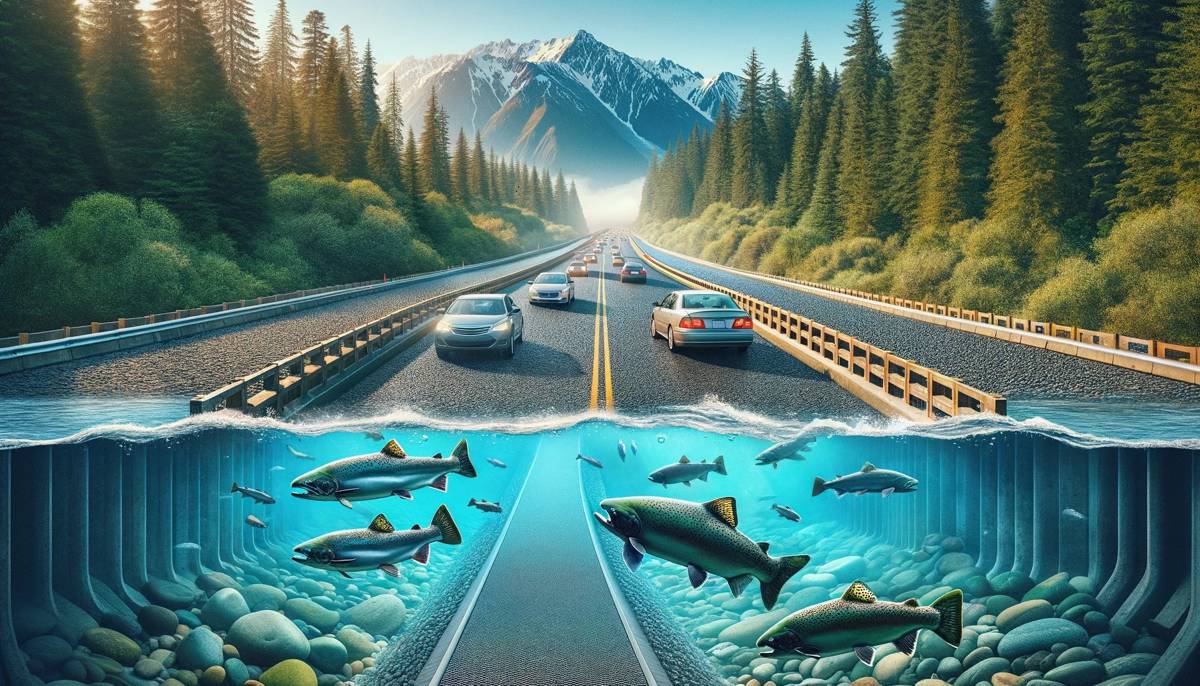

One of the main challenges on site is treating the domestic wastewater, such as the flushing of loos and draining of shower waters. This water can have a high Biological Oxygen Demand (BOD) and can contain a high concentration of ammonia, which if released to the watercourse, would deplete the dissolved oxygen within it, potentially killing fish and other aquatic wildlife.

To prevent this from happening, Siltbuster Process Solutions designed and installed a bespoke solution that primarily consisted of two HB20 units, tasked with separating suspended solids and associated organic matter from the waste stream, and an MBBR10, which provides the biological treatment stage. The solution also incorporates Clarity; Siltbuster’s new online, real-time water quality and monitoring system. This gives YB an accurate and up-to-the-minute overview of how effectively the system is working and provides a text-warning system if something was not working quite as it should have been.

Following an onsite consultation with YB, Siltbuster Process Solutions proposed locating its temporary treatment works on an area of land below the existing works. This eliminated the need for YB to pump wastewater in order to feed it, and instead leveraged the natural gravitational flow.

Iain Moir, Technical Sales Engineer (Municipal), at Siltbuster Process Solutions, explains: “By gravitating the flow of wastewater to our treatment works, we’ve negated certain issues, such as blockages, that can arise when using pumps. The domestic wastewater that our works treat contains rags and plastics, which can compromise how effectively pumps are able to work.”

Jordan Jones concludes: “Siltbuster Process Solutions’ solution has enabled us to easily meet our discharge criteria of less than 20mg/l BOD, 30mg/l total suspended solids and 10mg/l ammonia. Not only that, but its team of experts has trained our staff to operate the plant, and have been regularly visiting the site to ensure it is performing as it should be, and to discuss any small alterations that will help optimise the operations. Until the RBC is up and running, we’re safe in the knowledge that Siltbuster Process Solutions’ kit is keeping us fully compliant.”