OptiFuel natural gas Freight Locomotives aim to decarbonize the Rail Industry

OptiFuel Systems, a solution provider of zero emission rail, marine and generator products, is now taking orders for a new line of affordable 1,200 hp to 2,400 hp, 100% natural gas freight locomotives.

All of the locomotives use OptiFuel’s proprietary, EPA rail certified engine (KOFSG11.9400), which feature 0.00 g-bhp/hr NOx and PM criteria emissions. Powered by 100% RNG/Biomethane, the locomotives can have energy-weighted carbon intensity (CI) value ratings that are 200 to 300% lower than even a 100% battery-electric locomotive powered by renewable energy such as solar or wind. OptiFuel certified rail engine is based on the Cummins ISX12N. Since 2016, the ISX12N onroad engine has been utilized in more than 12,000 Class 8 long-haul trucks. With OptiFuel’s multi-engine configuration and instant stop and start capability, the fleet owner can expect to reduce fuel consumption by 20% to 40%, compared to a standard single engine locomotive configuration.

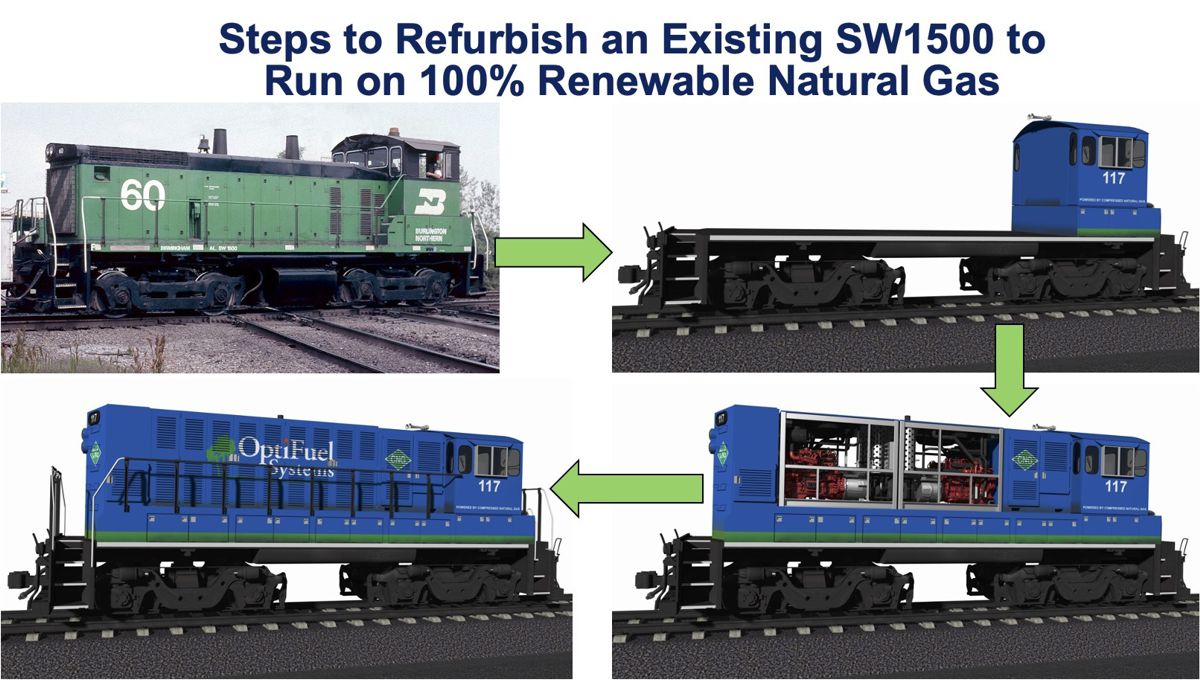

OptiFuel is capable of refurbishing most of the standard switcher and road switcher families (SW, MP, GP, SD, U, B, C, etc.) and lengths from 44 ft to 68 ft with modular components. Multiple modular KOFSG11.9400 engine pods can be incorporated into the overall design of the locomotive to provide for 1,200, 1,600, 2,000, or 2,400 hp. Each engine pod can be replaced within 3 hours with a forklift or crane. Customers have a choice of two different modular electronic controls manufacturers – TMV or Medha – containing the locomotive controls and high-power traction system electronics.

Depending on frame size, horsepower, size of onboard fuel storage system, and other options, the estimated cost for a completely refurbished locomotive is $1.7 to $2.4 million and a new locomotive is from $2 to $2.7 million. OptiFuel is also able to provide kits and assembly support, allowing the customer to provide preferred content in the final assembly of the locomotives. OptiFuel also has the ability to work with customers to arrange for leasing options, including dovetailing leases with grant funds, where permissible.

OptiFuel is providing a standard 5 year / 10,000 hours warranty for all engine pods, CNG onboard storage system, and locomotive controls. Total semi-annual and annual maintenance hours for each engine pod is 8 to 10 hours. Just as in onroad use, periods between locomotive engine overhaul are 18,750 to 25,000 hours with overhaul cost of around $20,000 per engine. All parts and supplies for the KOFSG11.9400, as well as the overhaul, can be purchased at any certified Cummins dealer or from OptiFuel. All CNG storage cylinders have a 20 years lifecycle, that may be extended to 30 years.

OptiFuel is providing a variety of mobile or fixed refuelling options depending on the operating conditions of a customer’s fleet. Customers can rent or purchase mobile refuelling equipment, or OptiFuel can manage the refuelling for the customer.

For those customers who refuel multiple locomotives from a single refuelling site, OptiFuel will provide its proven locomotive CNG fuelling station solution and expect the CNG to cost between $0.90 to $1.35 per DGE in most deployments. This is well below the 10-year average cost of $2.45 that the Class 1 railroads have paid for diesel. Customers can purchase the refuelling station or OptiFuel will cover the cost of the station and manage the refuelling for the customer for a fixed DGE cost.

In addition to switcher production, OptiFuel has a U.S. Department of Energy (DOE) grant to demonstrate a zero emission, 4,400 hp line-haul locomotive powered with renewable natural gas (RNG). This program will allow pre-production testing at AAR’s Transportation Technology Center, Inc. (TTCI) and will demonstrate in-service with a regional railroad to validate that OptiFuel’s low-risk, affordable technology can also be applied in the higher horsepower freight and passenger locomotive markets.

“We believe there is a need for locomotives that deliver value and cleaner, more economical solutions simultaneously to railroads, railroad customers, and urban and Environmental Justice communities,” said Scott Myers, President of OptiFuel. “Beyond Tier 5, EPA certified technology is available today. We think that in the next two years there will be a 50-state Low Carbon Fuel Standard (LCFS) program that includes rail and an extension of the existing federal Alternative Fuel Credit program to include rail. These programs, just as in trucking and aviation, will provide RNG to the railroads at a near zero cost and providing them the financial incentive to decarbonize their fleets over the next 15 years.”