How to properly maintain heavy construction equipment

Heavy construction equipment is like Atlas of Greek mythology — the great titan holding up the sky, or in this case, doing all the heavy lifting for a particularly weighty industry.

Each of these modern marvels needs regular maintenance to function correctly and prevent breakdowns. Here’s what it takes to maintain these machines properly.

Follow Manufacturer Recommendations

Every piece of equipment, from the smallest forklift to the largest excavator, comes with a set of maintenance instructions directly from the manufacturer. The exact details might vary, but in general, these recommendations will tell you when components need to be replaced, when the equipment should be inspected and what to do if warning lights start flashing on the dash.

These recommendations might seem excessive, but they’re based on years of research, experience and practical applications. No one knows better when the best time to replace a filter or relube a joint is than the manufacturer. Don’t skimp on their recommendations, and don’t ignore them. They’re in place for a reason, and while they might not cover all the bases you need, they’re a great foundation for building your own maintenance schedule.

Design Your Maintenance Schedule

Once you’ve learned about the basic upkeep needs for a piece of equipment, you have enough information to start creating your own plan and schedule. Take the time to customize it to your requirements. Figure out when you can best take a piece of equipment offline without negatively affecting your deadlines or work timeline. You don’t need to delay everything just to change the oil in an excavator or lube the treads of a big backhoe.

Work around your existing deadlines, but make sure that you stick to them once you set your maintenance schedule. It shouldn’t be something your team does only when they feel like it. Aim to be proactive, catching problems before they crop up, rather than responding reactively to issues when they take your equipment offline.

Create a Routine

They say it can take anywhere from 18 to 254 days to turn something into a habit, with an average falling somewhere around day 66. That’s how long it takes to rewrite the pathways in your brain so you can do something without thinking about it. You must reinforce these maintenance schedules to ensure they become ingrained in your team’s gray matter. The easiest way to do that is to make it a routine. Set up a series of steps for your employees to follow at the beginning and end of each shift. Include things like:

- Equipment walkarounds

- Inspection checklists

- Regularly scheduled downtime

- Red flags to be on the lookout for

Make it as straightforward as possible so there’s no room for interpretation or error. Then stick to it, every single day, until the routine becomes a habit. Using a project management software can help keep track of these routine maintenance tasks, but the organization system that works best for your team is what’s most important.

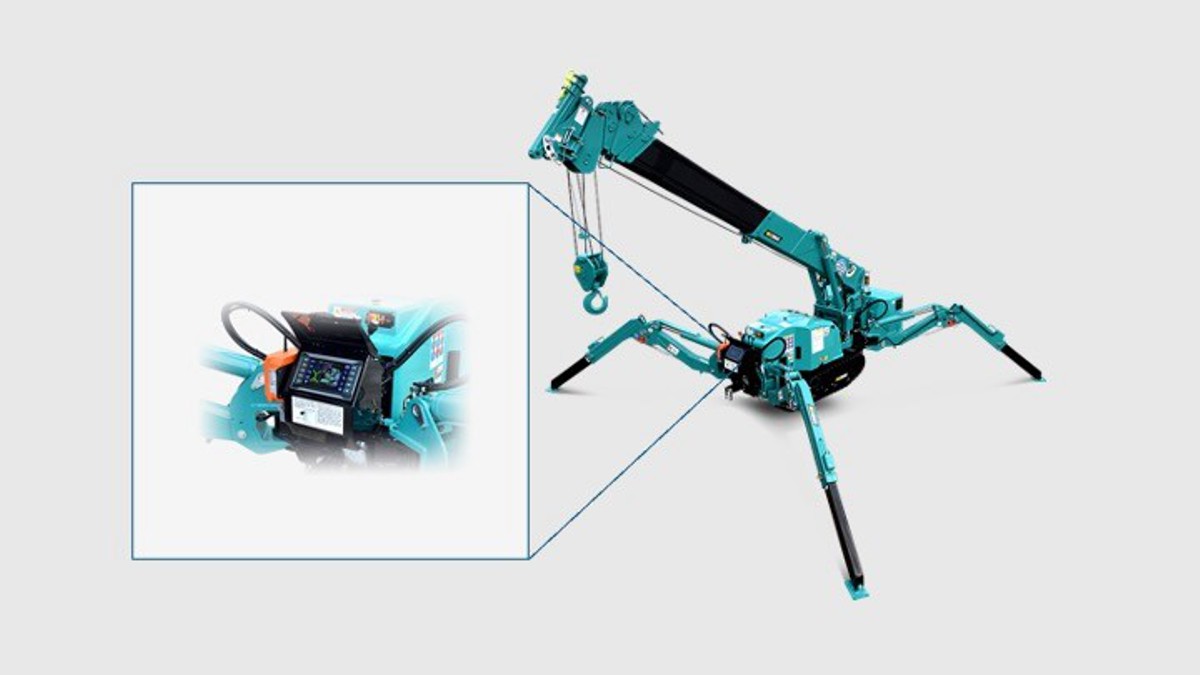

You will need to customize these routines for each type of heavy equipment you have on your job site. A crane might share basic maintenance or inspection steps with an excavator, but there are things unique to each device that you’ll need to address. Customizing your routines to each machine can help keep everyone on the same page even though they’re working on different tasks.

Train All Operators

Operators don’t necessarily need training in every aspect of equipment maintenance — especially if you have dedicated teams for that. However, they do need to understand the basics of how to care for their equipment. Ensure everyone is trained before they get behind the wheel for the first time. Research shows that comprehensive training, which includes both textbook and hands-on experience, can help extend your equipment’s lifespan and prevent small problems from becoming big ones.

Don’t rush through your heavy equipment training. This might sound like a disconnected suggestion, but spending time and money on employee education will reduce the amount of necessary maintenance. Consider this when you’re building your schedules and trying to structure that routine. The return on investment, in breakdowns and downtime prevented alone, is worth the expense of ensuring everyone is properly trained on your job site.

Be Mindful of Storage

Keeping your equipment on hand can help speed things up and ensure you meet deadlines, but storing it in the open can create several problems, especially in wet or humid environments. The No. 1 enemy of heavy construction equipment is rust, especially in areas that you might not spot during a casual daily inspection.

The easiest way to prevent this sort of environmental damage is to be mindful of your storage situation. Smaller equipment can be kept in garages or warehouses, while larger items might prove more challenging, depending on the sort of space and facilities you have available. However, you should try to store them indoors or keep them covered when not in use.

Keep Things Lubricated

There’s probably no worse thing to hear on a construction site than the shrieking, grinding whine of metal on metal — especially if it’s coming from a piece of equipment that isn’t supposed to sound like that. Regular lubrication is usually detailed in a machine’s maintenance schedule. However, if you work in a dry environment or spaces with lots of sand and other small debris, you may need to design an accelerated lubrication schedule to ensure everything works smoothly.

Don’t skimp on this step. It doesn’t take long for small problems to become big ones, especially when you’re using a piece of heavy equipment for hours or days on end.

Only Use Equipment as Intended

It can be tempting, especially once operators start to become comfortable with their machines’ idiosyncrasies, to begin pushing the devices to their limits and using them for things outside their intended applications. Using an excavator to lift and move equipment might work, but it also increases the risk of undue wear and tear.

Ensure everyone is only using a piece of equipment for its intended purpose. Don’t allow any leeway when it comes to these applications, especially if you’re concerned about maintenance. This is especially important if you’re renting your items rather than purchasing them outright. Using rental equipment outside of its intended purpose could void your agreement and leave you on the hook for repair or replacement costs if something breaks down.

Protect Your Investment With Maintenance

To an outside observer, maintenance might look like costly downtime, but it’s an integral part of operating heavy equipment and keeping it running smoothly. Taking care of your machinery through proper maintenance doesn’t just keep it running smoothly. It also makes your job site safer, reduces costly downtime and increases the lifespan of your fleet.

Taking proper care of heavy equipment starts with your manufacturer’s recommendations, but it doesn’t end there. Use this advice as a foundation to create a maintenance routine that will, over time, become second nature for your entire team. Taking care of your fleet will become much easier once it becomes a habit.