RoboSense launches Flash Solid-State LiDAR and Smart Manufacturing System

RoboSense, a world-leading provider of Smart LiDAR Sensor Systems, held a new product launch and Tech Day event. During the conference, RoboSense officially launched RS-LiDAR-E1 (E1), a flash solid-state LiDAR that sees 360° based on its in-house, custom developed chips and flash technology platform.

Also debuted was the only China National Accreditation Service (CNAS) recognized on-board LiDAR lab of the industry to date and held the unveiling ceremony of the smart manufacturing joint venture, Luxsense, jointly with Luxshare-ICT, a domestic leading electronics manufacturer.

RoboSense launched E1, the first automotive-grade flash solid-state LiDAR. It serves as a new product platform featuring area array transceiver technology with application-specific developed chips as the core.

E1 is designed for large-scale series production with a simple bill of materials including no moving parts and excels in all the three aspects of detection performance, cost efficiency and automotive-grade safety and reliability of LiDARs. As a key piece to realizing the core functions of autonomous driving, E1 will assist partners to further bridge the gap in smart driving perception and improve the all-scenario perception capability of automated and autonomous vehicles.

4 core features of E1

- Horizontal FOV of 120°, which ensures 360° coverage area without blind zone using minimum sensors.

- Vertical FOV is designed to be 90°, to allow the perception area to cover both blind zones on the ground and lateral vision.

- Ultra-high frame rates of over 25Hz, capturing target objects’ motion states and predicting their moves faster.

- Detection range of 30m @10%, which enables better perception planning control.

E1 uses RoboSense’s first in-house, custom chips for flash solid-state LiDAR platform and its first 2D electronic scanning technology. With highly integrated chips that incorporate the three core components of transmission, reception, and processing, E1 greatly streamlines the circuit design and production processes, creating the performance and cost advantages necessary for the durability and reliability requirements of blind spot LiDARs in the automotive market.

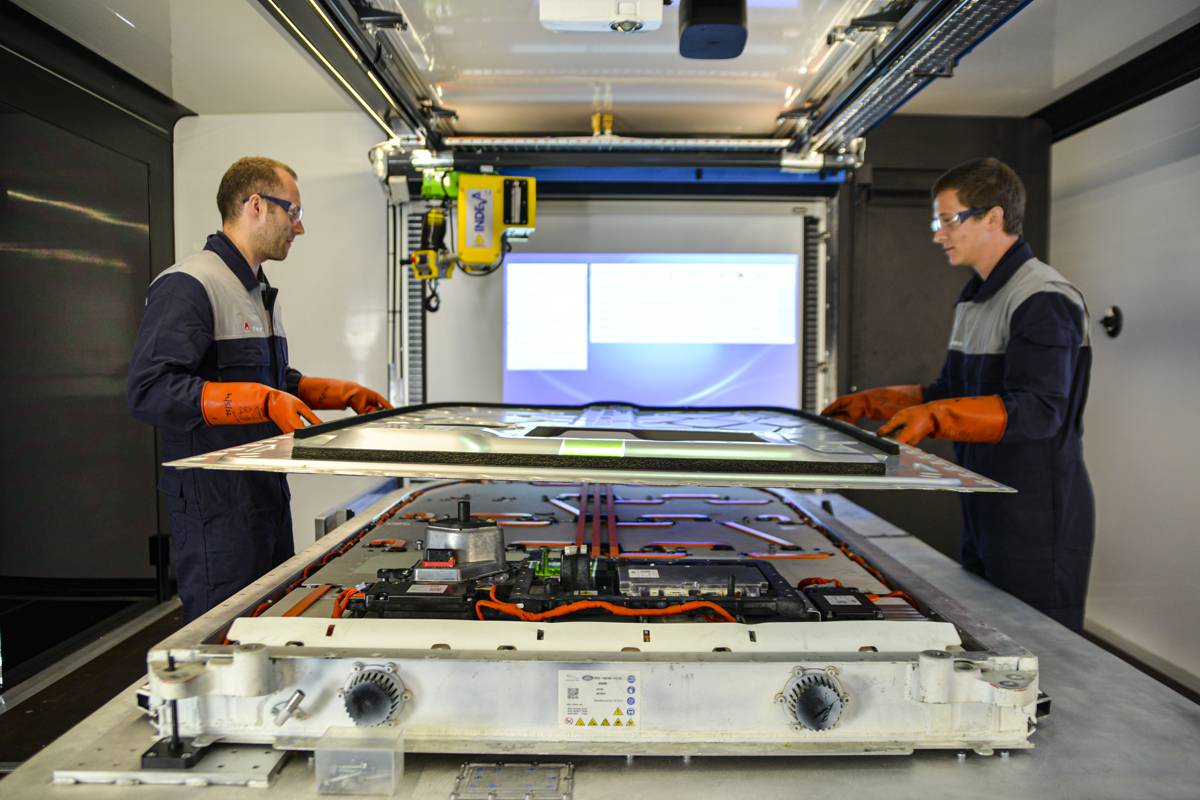

To ensure product performance and rapidly improve production capacity, RoboSense launched the first and only CNAS certified LiDAR lab to analyse LiDAR and their components and developed a complementary smart manufacturing system to produce this high-tech, precision sensor.

During the event, leaders of RoboSense and Luxshare jointly held the unveiling ceremony of Luxsense. Investment in the first phase of RoboSense smart manufacturing system exceeded 1 billion RMB cumulatively; the plant area exceeds 55,000 square meters including nearly 20 automated production lines built with highly intelligent production software to achieve a top-level production efficiency of “a LiDAR every 12 seconds” and guarantees capacity by connecting our Shenzhen, Dongguan and Guangzhou plants.

Additionally, RoboSense announced a new strategic financing round which attracted top industry investors. In particular, industry investors in this new financing round include car companies with self-owned brands, emerging automakers, top luxury supercar brands, leading commercial vehicle companies, supply chain pioneers and the tier 1 institutions. Greatly empowered by capital investments from the industry, RoboSense gained unprecedented momentum and sustainability

.

.